Reconfiguration of the PPS system and order processing

by Dr. Wolfgang Stock, Michael Hugger and Dr. Götz-Andreas Kemmner

Business processes are changing and so are the requirements for a PPS system. On average, these need to be renewed every 10 to 15 years in order to meet new requirements. However, before considering a new PPS system, you should check whether the reconfiguration of the existing IT system combined with a reorganization of order processing would not lead to a cheaper, more effective and faster PPS. The example of Orthomol GmbH in Langenfeld shows how the performance of a PPS system can be tested pragmatically but systematically for the future needs of a company.

Orthomol is one of the leading companies in the orthomolecular medicine segment. The therapeutic principle of orthomolecular medicine is based on the knowledge that the human body requires over 40 vital substances, i.e. vitamins, minerals, trace elements and essential fatty acids, for the healthy, smooth functioning of all organs. In the right quantity and concentration, they offer optimum health protection. Orthomol develops and distributes such balanced doses of complex mixtures of natural micronutrients. Founded in 1991, the company was a perfect match for the population’s growing health awareness. Following dynamic growth, the company currently has 157 employees and continues to grow rapidly.

Only in the beginning was “little” enough

Orthomol uses the Rick PPS system from KEC Computersysteme GmbH in Eltville. Due to its ability to trace batches down to container level, Rick is a system that is used primarily in the pharmaceutical, chemical, cosmetics and food sectors. Orthomol operates Rick in a Novell network with NT clients. The use of Rick started with the sales module, other modules followed, but not all modules were in use so far, so that important planning functions as well as the parts list and recipe management were missing.

With a dynamically growing business volume, it was clear to Orthomol that the existing implementation status of Rick could no longer meet the future requirements of the market for fast and cost-effective order processing and delivery reliability. The company was therefore faced with the alternative of revising the existing PPS system or switching to a new PPS system. Orthomol was looking for an experienced consultant to provide a reliable answer to this crucial question with major financial implications, as it was clear that this task could not be carried out internally with sufficient experience. This estimate is very realistic if one assumes that such changes can only be made every 10 to 15 years and that no employee in the company has sufficient practical experience.

Keeping costs low with a pragmatic approach

Abels & Kemmner’s project management proposal was decisive for the selection of the consultant: The project approach was based on the realization that the business processes running in the company are generally not designed in a way that would make sense from a business and organizational point of view. They therefore suggested that a framework concept for the future design of order processing and production organization be developed first. The existing PPS system should then be subjected to a requirements review, which is similar to a new selection. The advantage of this procedure is that the requirements developed can also be used for a new selection if this proves necessary.

Requirements profile and “sticking points” list

The developed PPS requirements profile consisted of a “sticking points” list on the one hand and a detailed catalog of requirements drawn from the PPS market survey of the Research Institute for Rationalization (FIR) on the other.

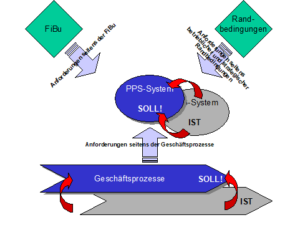

The “sticking points” list depicted the acute problems users had with the existing PPS solution and defined the desired future operating process, which was worked out in advance with Orthomol employees. The requirements for the interface between PPS and financial accounting as well as operational and strategic constraints were also taken into account. The latter included, in particular, requirements for the software provider and the software that could not be collected from the FIR market survey.

The requirements catalog created in parallel described all future software-specific or “state of the art” requirements for a new PPS system. Decisions were made here, for example, on detailed functional requirements such as the number of planning levels required or the necessary procedures for rough order scheduling. The organizational requirements resulting from the analysis and redesign of the operational processes were translated into the technical requirements catalog by the consultants in coordination with the IT department and the management. We also deliberately avoided setting knock-out criteria and involving the entire project team. This avoided three problems:

- A technical-functional catalog of requirements is too much for most normal system users in a PPS selection team from a technical point of view

- Requirements catalogs easily tempt PPS selection teams to adopt a “mail-order catalog” approach. You choose what sounds interesting and exciting without always critically questioning whether a certain functionality is really needed.

- Excessive knock-out criteria (mandatory requirements) filter out many good systems and mean that only the most complex systems on the market can fulfill the requirements.

The chosen approach avoided these pitfalls, saved time and made it unnecessary for Orthomol’s project staff to have to deal with the abstract PPS terminology.

PPS system in the shortage

These lists were then used to review the existing system. After a preliminary examination showed that a large part of the formulated requirements were met or exceeded by the Rick system, a two-day workshop was held to discuss the points that Rick could not easily fulfill. The more complex issues were then reproduced on the IT system. The moderated discussion showed that the difficulties in purchasing, for example, could be solved partly organizationally and partly through better system support. Orthomol’s requirements for the phase-in of new products and phase-out of discontinued products could even be solved purely organizationally without changing the functionality of the system. Such pragmatic problem-solving would certainly be more difficult without external moderation, because which specialist would be happy to have the process organization changed by a PPS manufacturer?

However, Rick was unable to find a solution that sufficiently met his requirements: In the area of sales forecasting and, in the medium term, the optimization of material planning, no in-house solution was available or could be programmed under realistic financial or time constraints. However, as these requirements could not be met by Orthomol, even by many other PPS systems, the use of a scheduling and forecasting module from a third-party manufacturer was suggested as a possible alternative.

Decided to optimize the PPS

After a cost estimate between the revision of the existing PPS system and the introduction of a new PPS system showed a cost advantage of 1:3 for the reorganization of the existing system, the project team came to the decision to stick with the Rick system and to optimize order processing and the IT system. A joint project team from Orthomol, Abels & Kemmner and the system provider is currently working on this task. The aim is to go live with the completely restructured PPS from July 1, 2001.