How to cope better with a slump in sales

by Dr. Götz-Andreas Kemmner

Companies that continuously work on their competitiveness can more easily absorb slumps in sales. However, competitiveness is more than just productivity. If you only focus on growth and productivity, you have to resort to more drastic measures in bad times.

More and more companies are struggling with enormous growth rates and slumps in turnover in short cycles. Successful entrepreneurs can withstand such fluctuations, which last year amounted to more than 30 percent in the electronics industry. They live with these ups and downs because they can always react flexibly. “Normal” Entrepreneurs have not yet prepared for the new economic situation. But no company today is immune to a slump in sales. This is demonstrated not least by the current economic situation, which is forecast to pick up speed again in a few months. But do we really know? Who didn’t want to invest in shares again last April after prices had already fallen sharply at that time? However, now is not the time to worry, but to rethink and act in order to ensure the flexibility and competitiveness that will allow you to safely absorb major sales losses.

The most important principles of action

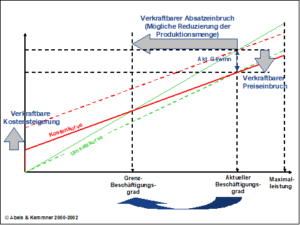

- Lower the marginal employment rate by reducing fixed costs. We define the marginal employment rate as the level of employment at which sales just cover costs. The lower the marginal employment rate of your company, the further the production volume can be reduced without incurring losses. The lower the marginal employment rate, the greater the increase in costs or reduction in product prices that can be absorbed. Accept higher variable costs to a certain extent.

- Reduce variable costs continuously through productivity improvement measures. This makes your productivity (more) independent of your level of employment! A tip for finding productivity improvement potential: Unspoken laws and company principles are often the cause of inefficiencies that have never been addressed in the past.

- Streamline your organizational structure: As the productivity of production workstations is easier to measure than the productivity of office workstations, many companies tend to “eat their bacon” in the administration department when times are good. In practice, the potential for reducing administrative staff is regularly overlooked.

If you work continuously and hard on these principles, the next recession will have less of an impact on you.

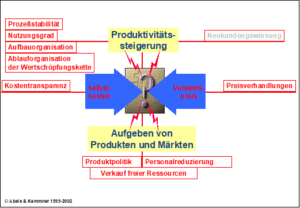

Ultimately, the problems in a recession or a sales crisis begin with the fact that sales cannot cover the cost price. Once the situation has arisen, it is usually not possible to increase sales in the short term by means of marketing measures and sales efforts. There are only two ways to tackle the earnings problem: either increase productivity or give up unprofitable markets and products.

Low productivity and high fixed costs lead to failure

The example of a Dutch group that has expanded in recent years by acquiring several production sites in Germany shows how this cannot be done. However, not all of the acquired locations were organized particularly efficiently. Some of the locations were up for sale precisely because they had hardly made any money in the past. In the years of the electronics boom, with all companies operating at practically full capacity, the high investments in new locations paid off. However, when the high-tech economy collapsed, capacity utilization problems quickly arose. Production systems for electronic PCB assembly require high capacity utilization anyway in order to generate profit margins. Due to their poor productivity, some of the Group’s companies found themselves in shallow waters very early on. Instead of at least reducing the flexible production capacities at the individual locations, the decision was made to close a plant in northern Germany in the hope that this would improve capacity utilization at the other plants. It was realized too late that the costs of closing the plant were too high to be able to afford in the current economic situation. However, the reduction in capacity at the other locations had been delayed for too long to be able to reduce costs sufficiently in time. The entire group went bankrupt in the fall of 2001. Neglecting productivity and tolerating high fixed costs therefore makes no sense in the long term.

Productivity increase

The economy is not just on the up. A company that is not in the top third of the competition in terms of productivity has not done its homework. Improving your own productivity costs money and must be tackled at times when you are earning money. Many companies therefore miss the right time. When the market goes flat, sales collapse or your own products are no longer competitive, it is too late for long-term productivity measures. However, a number of measures can also lead to initial successes in the short term. Examples of this are

Rethink work processes in principle

Incorrect workflows and unnecessary work steps are hidden in practically every value chain, you just have to have an unbiased eye to spot them. In order to achieve significant leaps in productivity in the short term, “operational axioms” need to be questioned. Unspoken laws and business principles are often the cause of inefficiencies that have never been addressed in the past. In a large German company, we were able to reduce the personnel costs of a division by around €400 thousand by breaking through a corporate paradigm and switching the audit to a random check.

Recognize production bottlenecks

Beyond unnecessary work processes, it is often individual bottleneck workstations that determine the performance of an entire production department. In the case of stable bottlenecks that can be identified directly, significant leaps in productivity can be achieved by increasing the utilization time or the degree of utilization (see below). In most cases, dynamic bottlenecks are encountered that are difficult to recognize. Tip: It is often not the longest queue that marks the bottleneck, but the queue with the greatest work content for subsequent workstations.

Improve utilization rates

In many production plants, the degree of utilization can be increased through simple continuous improvement measures. For this purpose, downtimes and reasons for downtimes are recorded manually in the simplest case, corrective measures are determined and implemented. Sounds simple, is simple, but is not handled consistently in most companies. In one refurbishment case, we increased the added value per hour worked by almost 47% within 12 months.

Reduce luxury

A few years ago, we had to deal with an insolvent medium-sized automotive supplier. The company had already been experiencing earnings problems for some time. Not only did they afford an extremely expensive technical center that did not correspond to their own size and needs. The company’s own hunting lodge, forester and house staff were retained until the very end. Compared to what we experienced for a long time in the so-called “new economy”, the hunting lodge was a modest hobby. The boards of directors of companies that had never earned a cent were buying company jets and luxury sports cars, willingly financed by a venture capital industry that had apparently come to the realization that you don’t have to earn money, you just have to spend it. Business magazines scrambled to name people Entrepreneur of the Year who had not yet proven for a second that they could make money.

Hidden luxuries can be found almost everywhere, even in companies that pride themselves on their thriftiness. It’s worth looking for them!

Discontinuation of products and markets

Every innovative company struggles with unprofitable products and markets. Which new product, which new market will generate income from day one? However, abandoning unprofitable products and markets is an art that only the most successful companies have mastered.

Scrutinizing new products and services

Every company is working on new products or new services that cost more than they bring in in the short term. Such projects are very important for a company because they secure tomorrow’s turnover and separate the entrepreneur from the underperformer. But you have to be able to afford them. It is usually easier to fight through an idea or a project against all odds than to bury it because it does not promise sufficient returns in a reasonable amount of time.

In crisis situations, it is therefore essential to scrutinize all products, services and new developments that do not generate a contribution margin. This insight sounds banal, but we regularly come across “cash burners” in our projects that the management simply didn’t want to part with. Reference is then always made to the imminent breakthrough in development or on the market. If you scrutinize the situation, it becomes clear that people have been clutching at straws for months or even years.

Sometimes a project can be frozen in order to reactivate it later, but often a stop also means the end of a project. We can only recommend that you consult an independent advisor in good time who is not involved in the social structure of the company and whose judgment is therefore not impaired. The projects should be jointly evaluated and prioritized in terms of their prospects of success, their ongoing and termination costs and their interruptibility.

Review existing products and services

Not only new products, projects and services need to be put to the test, but also existing ones. It’s a bold statement, but I stand by it: in eight out of ten companies, cost accounting is so bad that you can’t tell from the figures whether you’re making or losing money with a product or service. We regularly encounter this problem in reorganization and restructuring projects and have therefore made it a habit to critically scrutinize the quality of cost accounting before working with the figures provided. I have already seen numerous reports from renowned management consultancies that may have been brilliant in their conclusions, but unfortunately were based on incorrect cost structures.

You almost always discover products that do not generate any contribution margins in general or in certain markets. Fig. 1 shows what to do

Create profitability or reduce resources.

If you have discovered unprofitable products, projects or services – both new and established – you should first check whether you can make them profitable in the short term. This will rarely be achieved through price increases, but will mostly require productivity measures. Anyone struggling with earnings problems not only has no money, but also no time. In the case of “dark red” products, no time should be wasted examining measures to increase productivity, but the products should be buried immediately. With “bright red” products, on the other hand, initial productivity measures often take effect in good time.

Numerous operational resources in the form of the “4 M’s” are attached to the products or services that are removed from the performance program,

- Moneten” (=financial resources, at least in the form of capital commitment),

- Material,

- Machinery (= real estate, equipment, consumables and supplies) and

- people (= direct “productive” production and assembly personnel and indirect, “unproductive” administrative personnel (overhead)),

which need to be reduced, thereby improving the cost structure. Firstly, it is important that these cost factors can and are actually reduced. There is little point in trying to save a quarter of a person and a third of a machine in 10 places in the company. In the end, nothing remains of these imputed savings.

Secondly, it is important that, in addition to the production staff, the number of administrative staff is also adapted to the downsized production structures and thus reduced. This is more difficult than in production, as the organizational structures do not grow proportionally with turnover, but in stages. With this reference, managers often try to limit the reduction in the administrative workforce, especially as the administrative workforce is closer to them than the production workforce. In practice, the potential for reducing administrative staff is regularly greater than companies are willing to admit. If there is no chance of returning to the previous size in the long term, the potential for redundancies in administration is sometimes disproportionately greater than in production, as the company can be converted to simpler organizational structures.

As the productivity of production workstations is easier to measure than the productivity of office workstations, many companies also tend to “eat their bacon” in the administration department when times are good.

Thirdly, it is important that staff who are no longer needed are actually made redundant. This statement sounds banal, but it is regularly the biggest problem. This begins with line managers, who often find it difficult to specifically name people for redundancy measures, continues with the social selection process, which rarely leads to an efficient remaining personnel structure, and ends with severance payments and social plans, which many ailing companies are no longer able to pay because they react too late or have not made provisions. The fact that German labor law is responsible for more corporate insolvencies and unemployed people than all bad business decisions put together is of little use in an emergency. Nobody is forcing us to play entrepreneurs in Germany, but if we choose to do so, we are forced to play by the rules. But cheer up, in practice there is more leeway than you would expect in theory. Get support from an experienced consultant who knows how to do it. Small and fine consulting firms can achieve more here than large ones, which often represent a red rag for the employee side.

Prevention is better than cure

It certainly makes more sense to work continuously on competitiveness than to fight for it in the first instance under time pressure. Productivity is an indispensable prerequisite for being and remaining competitive, but productivity alone is not enough. There must be something else to it…

Productivity is vital

We all have a more or less precise idea of what productivity means. According to Brockhaus, productivity is the measure of a company’s economic efficiency, performance and competitiveness. The aim is to achieve the highest possible production result with the least possible use of resources (“4M”; see above). In other words, the aim of any increase in productivity is to reduce manufacturing costs, especially variable costs. Those who are more productive than their competitors, i.e. who have lower production costs, can lower their sales prices more than their competitors in a weak economic situation. Despite lower margins, it is still earning money, while some of its competitors have already had to give up the ghost. The market and pricing function according to this principle in some sectors, e.g. in parts of the chemical industry, in the steel industry or in agriculture, provided the public sector does not intervene in the market structure to regulate prices.

The principle here is: Keep the degree of utilization (capacity utilization) and thus the output as high as possible and, if necessary, reduce sales prices. Whoever can reduce their sales prices the furthest without losing money will survive.

In many sectors, it is not so easy to reduce prices.

Reducing sales prices is quick; raising them back to their original level can take years. Many markets are now so saturated that even drastic price reductions can hardly keep output up. Ultimately, higher productivity can also entail running costs that condemn you to a higher volume output that you cannot maintain in bad times. Let’s take a look at the example of a medium-sized German food company. A supply contract with a large retail company required the automation of production capacities in order to increase production volumes and manufacture them sufficiently cost-effectively. In the following 2 years, the demand for this product increasingly declined. The scope for price reductions in the form of special promotions was quickly exhausted. Due to the expensive production facilities, a reduced volume output inevitably resulted in losses. Today, parts of the company are in new hands and parts no longer exist; a German success story turned into a drama.

We see that productivity alone is not enough. You must also be able to adjust your costs flexibly to the capacity utilization situation.

Ensure a low marginal employment rate!

In business administration, the capacity utilization rate is referred to as the degree of capacity utilization. The capacity utilization rate represents the ratio of actual production output to potential production output. By the marginal employment rate, we mean the level of employment at which sales just cover costs (see Fig. 2). The lower the marginal employment rate of your company, the further the production volume can be reduced without incurring losses. The lower the marginal employment rate, the greater the increase in costs or reduction in product prices that can be absorbed.

How can the marginal employment rate be reduced? Making costs more flexible is the key buzzword when it comes to reducing the marginal employment rate. Lower fixed costs reduce the marginal employment rate. In return, variable costs can be increased to a certain extent.

A low marginal employment level gives you scope for decision-making. You can try to reduce prices and maintain sales, or you can maintain your price level but reduce sales figures.

Focus on productivity and marginal employment rate

If lower fixed costs are bought with higher variable costs, which is often unavoidable, this lowers the marginal employment rate. However, earnings power is reduced during economic phases. Paying attention only to the marginal employment rate is therefore only half the truth. You need to keep an eye on both productivity and the marginal employment rate.

The principle of action is therefore:

Lower the marginal employment rate by reducing fixed costs. Accept higher variable costs to a certain extent and continuously reduce variable costs through productivity improvement measures. This makes your productivity (more) independent of your level of employment! If you work hard on this principle during the next economic phase, the next recession will have less of an impact on you.