Reengineering the supply chain at Montblanc

by Burkard J. Kiesel1 and Dr. Helmut Abels

Abels & Kemmner optimized the delivery readiness and inventory management at Montblanc-Simplo GmbH, Hamburg. Production planning and warehousing along the supply chain were significantly changed by the reengineering project. Central planning was upgraded, sales planning was refined with the help of Diskover 4.1 and linked to SAP R/3 (SOP). Today, demand peaks and supply bottlenecks can be recognized earlier despite the wide range of variants and seasonal business and can therefore be reduced in good time.

Sales planning for Montblanc’s luxury goods was previously submitted monthly by the respective sales locations with country-specific split factors, recorded centrally and processed further for procurement and production purposes as well as for supplying the national warehouses. With around 1,000 product groups and 3,000 articles today, this planning method proved to be too complicated, too labor-intensive and increasingly less accurate. For this reason, the management initiated a reengineering of the entire planning process in spring 2001, which extended from budget planning and the forecasting process to rolling monthly requirements planning and supply of the Landersläger.

The result is a clear separation between strategic and operational planning. In future, the planning input of the sales locations will focus on strategic planning at a highly aggregated product level with approx. 120 items to determine the “route” for production and procurement. Operational planning works exclusively at item level and is divided into two independent control loops that follow the same methodology.

A replenishment system is set up to supply the national warehouses, which is managed by the national logistics provider with clear inventory responsibility.

At the same time, the role of planning and inventory management at the Hamburg site will be significantly enhanced: In future, the Hamburg central warehouse will increasingly be responsible for ensuring delivery readiness. To cope with this new task, a two-stage planning approach was developed together with the consultants from Abels & Kemmner:

1. the Logistic Category Managers (central sales logisticians), who are organized by product area, will in future be responsible for item-specific sales planning from the central warehouse. Its central task is to determine the future sales requirements per item as accurately as possible, taking into account all available information. This determination is initially made independently of all capacity restrictions. The logistics category managers are responsible for this and are measured by the quality of their planning.

2. the planning data determined in sales planning is then used by production control and procurement for capacity planning of in-house production and for coordinating component procurement with suppliers. Expected future peaks in demand can thus be recognized and managed in good time.

For the practical implementation of this planning approach, the articles will in future be analyzed with the DISKOVER 4.1 scheduling optimization software from Abels & Kemmner, firstly with regard to their planning capability and then the optimum planning procedures and parameters will be determined. The easily plannable AB-XY articles (approx. 30% of all articles) already account for 66% of sales and more than 75% of annual production capacity. DISKOVER forecasts the future planned requirements for these items and transfers them to the SAP system’s Sales and Operation Planning (SOP). The SOP planning table was tailored as a central planning tool for coordination with production program planning: Based on expected sales, the production and procurement quantities are initially planned on a rolling monthly basis, taking into account the capacity utilization of the affected workstations and machines along the supply chain. If there is a risk of capacity overload during a period, the necessary smoothing measures, e.g. bringing forward partial requirements quantities, can be planned in advance in the SOP tableau.

Structured approach to optimizing item-specific sales planning

The structured approach to item classification developed by Abels & Kemmner was implemented to determine the appropriate planning procedures for each item in the context of sales planning:

In future, the item-specific requirements occurring across all sales companies will be cumulated per time unit and then analyzed in terms of sales significance (ABC analysis) and existing demand behavior (XYZ analysis). This study was carried out using the DISKOVER 4.1 scheduling optimization software from Abels & Kemmner. The analysis of demand behavior includes a trend and seasonal analysis for each item as well as an analysis of demand regularity. Each article is therefore assigned to both an ABC and an XYZ class. The results of such an analysis can be presented in an aggregated ABC-XYZ portfolio.

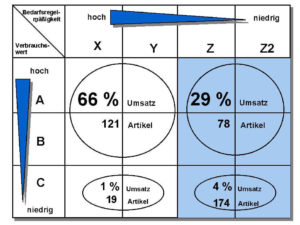

Figure 1 shows an example of such an item portfolio for a main product group (product category). X and Y articles exhibit regular demand behavior with small to medium fluctuations. These articles are easy to forecast. Z and Z2 articles, on the other hand, have a sporadic demand behavior with considerable fluctuations, which can also arrive completely unprepared. Future requirements are difficult to forecast. A different planning method is therefore recommended here, e.g. reorder point or minimum stock planning.

DISKOVER 4.1 is also used to determine the optimum planning procedures and parameters as well as the expected stock levels for the desired target delivery readiness levels for each item class. For each item, the expected average stock levels are simulated for different degrees of readiness for delivery and the optimum combination of process and degree of readiness for delivery is selected. The forecast values for sales planning are then determined for X and Y articles and transferred to the SOP (Sales and Operation Plan) module of the SAP system. Reorder points and safety stocks are determined for Z and Z2 articles and transferred to SAP for reorder point planning.

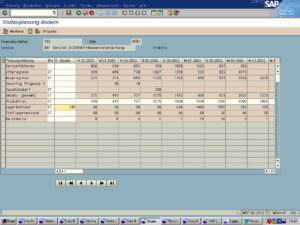

In future, it will be the task of the Logistic Category Managers to check the transferred plan values in the SOP planning table. The planning table was adapted accordingly (see Figure 2). In principle, the Logistic Category Manager has access to both last month’s forecast and the current new forecast. He decides which forecast he wants to use for the further planning of the article. It can also take into account additional requirements in the form of percentage surcharges or exact additional quantities per month based on the findings of the trend report or for unforeseen special orders. All demand quantities are then cumulated to form the sales volume (total). This line Sales (total) is the decisive quantity target per month for production and procurement.

Coordination of capacities along the entire supply chain possible at an early stage!

Production control and procurement planning will also use the SOP planning table in future: based on expected sales, they can plan production or procurement quantities in good time or order partial quantities earlier, taking into account the capacity utilization of the workstations and machines concerned along the supply chain. This is particularly relevant for Montblanc, as the company has a pronounced seasonal business, which makes this coordination and adjustment essential, especially to cope with the strong sales quarters. The key parameter in this reconciliation is the target stock level. The target stock level is determined by DISKOVER together with the planned values of the forecast and transferred to SOP. It has the function of a safety stock and serves to hedge against random, unplannable deviations from the planned values in future periods. The reconciliation process in the context of production control and sales planning is then carried out in such a way that the production and procurement quantities can be varied to the extent that capacity bottlenecks can be avoided on the one hand and the target stock level is always available in future planning months on the other. For this purpose, SOP offers the option of displaying the current capacity situation. For each planning month, all affected capacity loads can be displayed for the current article or planning group. If there is already a recognizable capacity overload in a planning month, the planner can shift the required quantities or partial quantities to other months and thus avoid the impending capacity bottleneck. In future, Montblanc’s main suppliers (e.g. leather) will be included in this coordination so that capacity can be synchronized along the entire supply chain at an early stage.

Over 75% of the production capacity can be systematically planned!

Figure 1 shows for a product category that not only the A articles account for approx. 80% of the sales volume, but also the AB-XY articles already account for 66% of the sales volume. These 4 article classes only comprise approx. 30% of the total number of articles in this product category. This finding is so important because these are the items that are easy to forecast and for which the procedure described above using the SOP planning table is applicable. In addition, start-up planning for new products will also be carried out via DISKOVER and the SOP planning table in future. A review of the capacity requirements for these articles shows that AB-XY articles already account for around 75% of the company’s own annual production capacity and, including new products, more than 80% of annual production capacity. This means that a large part of production can already be planned in advance using the above planning methodology. Although the remaining capacity requirement is distributed over approx. 75% of the range of articles, these articles only occur sporadically (difficult to predict) and are used to replenish production.

Results and further measures planned to optimize the supply chain

The planning methodology presented is currently being piloted in two product categories. The primary objective is to ensure a high level of supply readiness for the national warehouses. At the same time, inventory levels at the national companies will be reduced to a level that can be replenished from the central warehouse. As a further support measure, the reengineering of our own production according to the Kanban principle is currently in preparation. The aim here is to achieve a significant reduction in inventories, particularly for sporadic Z and Z2 items, as the high level of vertical integration and the resulting long replenishment times mean that considerable reorder and safety stocks still have to be held.

1BurkardJ. Kiesel has been Director of Technology at Montblanc-Simplo GmbH since April 1, 2002 and has been the main project manager for the entire reengineering project for the past 15 months.