Inventory and production optimization with a simple rule: 80/20

by Gerd Däumler and Helmut Abels

If you want to gear your production and warehouse to the highest possible readiness for delivery, you should follow the 80/20 rule. It states that around 80 percent of sales are made with around 20 percent of items and that special attention should therefore be paid to these items. The Decorations business unit of Ferro GmbH, Frankfurt, has had good experience with this. After capacity planning was changed to a utilization rate of around 80% for stock replenishments and only those items that account for around 80% of sales were stored in the warehouse, the level of delivery readiness was increased to over 98%. At the same time, the value of inventories was reduced by more than DM 2 million.

In recent years, Ferro GmbH’s Decorations business unit has seen a sharp increase in demand for decorative paints, precious metal preparations and organic decoration additives, which are used for high-quality decorations on ceramic substrates (porcelain, bone china, earthenware, enamel) and glass. This was an extremely pleasing development, as the associated high levels of capacity utilization seemed to ensure an optimal cost structure.

However, the high capacity utilization blocked the flexibility to react quickly to important customer requests. To counteract this, special rush orders were introduced, which were to be given priority in production. However, this meant that the number of rush orders increased steadily and production plans had to be constantly revised. In the age of modern PPS systems, this was not a particular problem, but this approach did not lead to the desired result of high delivery readiness, because

- Constant planning changes put production in a permanent state of unrest

- Machine or personnel-related downtimes increase the pressure and inevitably lead to a reduction in delivery readiness with demand-synchronized production and borderline capacity utilization planning

- Production also ran the risk of being increasingly divided into smaller batch sizes due to rush orders, which would lead to an increase in set-up times

To avoid this, stocks in the warehouses for intermediate and end products would have had to be increased if production planning had remained unchanged. However, these had already taken on considerable proportions. It was therefore imperative to take a close look at the existing overall concept for planning and controlling order processing. It was necessary to estimate to what extent an optimization of the production throughput time could be realized and to what extent stocks would then be required to ensure delivery readiness.

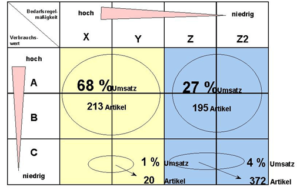

Abels & Kemmner’s first task was to examine the material flows in the entire logistics chain and to determine the capacity situation in production and the warehouse. The data obtained quickly showed how Ferro could achieve better delivery readiness: The item assortment not only represented the classic 80/20 rule, according to which 20% of items generate 80% of sales, but also the realization that two thirds (68%) of sales are attributable to a quarter (27%) of the item range, which includes regular and therefore easily plannable items (see chart). However, this weighting was reflected neither in production nor in the warehouse.

Warehouse contains a disproportionate amount of materials for C/Z items

For historical reasons, for example, there were still a disproportionately high number of materials in the warehouse that belonged to the C/C items in the period under review of the last 12 months or that did not show any movement at all. In addition, production was interrupted too often by rush orders, which meant that the throughput time for orders was sometimes up to three times longer than the actual process time required. At the same time, three times as many intermediate products were stored at the plant. The solution to the problem was therefore obvious.

Today, Ferro plans and manages its production and the associated warehousing and material procurement according to the 80/20 principle. This means that the products in categories AB/XY are stocked and continuously taken into account in production planning with approx. 70-80% capacity utilization. The remaining items (C/Z items) were largely removed from stock and only ordered and produced as required.

The result of this simple planning approach is enormous: the stock level has been reduced by more than 2 million stock value. This improved both the company’s liquidity and its earnings situation, as the warehousing costs required for these stocks (insurance, warehouse management costs, interest on tied-up capital, etc.) are no longer incurred. On average, series and variant manufacturers such as Ferro assume that this is around 15 to 25 percent of the stock value.

The significantly lower number of express orders now only affects weekly planning in exceptional cases. Depending on how incoming orders develop within the planning time frame, later scheduled stock replenishments are brought forward if machine capacities are available. Decision-making authority was largely transferred to the production managers, which led to a significant improvement in self-direction skills and the working atmosphere.

The 80/20 planning approach

Empirically, in most companies there is a certain distribution of importance of the articles, which approaches the “pi times thumb” guideline value of 80/20. It states that around 80 percent of sales are made with around 20 percent of items and that special attention should therefore be paid to these items. In detail, attention must be paid to the significance of sales and earnings and the sales frequency if you want to optimize stock, production and delivery readiness. This is also referred to as the ABC/XYZ analysis. Once this analysis has been carried out, optimal production and inventory optimization can be implemented using scheduling procedures. For AX articles (high turnover/regular orders), different disposition procedures apply than for CZ articles (low turnover/irregular orders).

About Abels & Kemmner

The medium-sized Abels & Kemmner Gesellschaft für Unternehmensberatung mbH, Herzogenrath, was founded in 1993 by Helmut Abels and Götz-Andreas Kemmner, who both have a doctorate in engineering and economics. The company focuses on streamlining value chains (supply chain optimization) for series and variant manufacturers as well as wholesalers. In addition, the consultants have made a name for themselves in crisis and turnaround management through successful corporate reorganizations. Abels & Kemmner clients’ supply chain concepts have already won two Best Practice awards following a redesign.

Abels & Kemmner caused a sensation in 1997 with the founding of the first virtual company made up of six medium-sized companies in the automotive supply industry. Today, the consultants at Abels & Kemmner work in four networked teams for supply chain optimization, turnaround management, IT consulting and IT-supported inventory management. They have generated constant growth of 20-25% in recent years.

Authors:

Gerd Däumler is Head of the Decorations division at Ferro GmbH

Dr. Helmut Abels is Managing Director of Abels & Kemmner