Inventory optimization for non-series material

Stabilus GmbH, Koblenz, was looking for a new solution to optimize inventory management based on the SAP system used for non-series material – i.e. purchased parts that are not or only indirectly related to production at a series manufacturer, such as office and general consumables, maintenance material and tools. After a three-month test phase, Stabilus decided to use DISKOVER 4.1. (DISposition with the help of confidence intervals, taking into account the actual stock issue distribution).

Uwe Mollenhauer, Head of International Logistics, Production Control and Material Scheduling (SILS) at Stabilus: “DISKOVER enables us to optimize stocks quite elegantly at the level of agreed delivery readiness for the large number of our non-series materials.”

Stabilus GmbH in Koblenz is a manufacturer of systems for hydraulic damping and adjustment of flaps, doors and seats in numerous industrial applications. A large area of application for the products is in the automotive industry, which has had a significant influence on the handling processes in the area of procurement and production of series materials. The area of non-series materials is structured quite differently. They are subject to natural fluctuation and cannot be optimally planned using standard parameters, which generally provide for a normally distributed stock issue. Why? In practice, the proportion of normal distributions in outgoing stock is only around 5%. However, a relatively large proportion of the distributions (approx. 25 %) cannot be assigned to any theoretical distribution type at all. Stabilus was looking for a solution in SAP for the scheduling of non-series items, which often cannot be assigned to a theoretical distribution type, with which non-series material can also be scheduled as easily as possible and found it in DISKOVER.

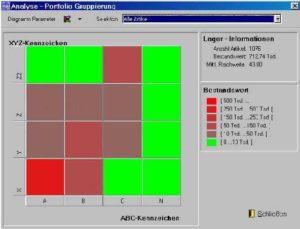

DISKOVER now works together with the leading SAP system to determine the optimum scheduling procedures and parameters. The MRP system is characterized above all by its methodical approach in two successive stages: First, the parts are arranged in an article structure according to demand and consumption behavior. For each item class, the optimum scheduling procedures and parameters are then determined with regard to stock levels and the required readiness to deliver. These parameters are then transferred to the leading HOST system (in this case SAP) or used directly in DISKOVER to determine the order proposals for parts procurement. Item-specific basic requirements and safety stocks are determined taking into account a specified target delivery readiness level and the actual distribution of stock issues and replenishment fluctuations in the company.

About DISKOVER

The DISKOVER 4.1 scheduling system is an operational management system for optimizing the supply chain from purchasing to delivery. It is characterized by extensive selection mechanisms for daily planning as well as by its portfolio analysis and simulation functions. DISKOVER also offers distribution-free scheduling procedures. DISKOVER (DISposition with the help of KOnfidenzbereiche under consideration of the actual stock issue distribution) is executable as an add-on tool under SAP and all common ERP, PPS and WW systems. The use of DISKOVER is generally worthwhile from an average stock value of around € 2.5 to 5 million.

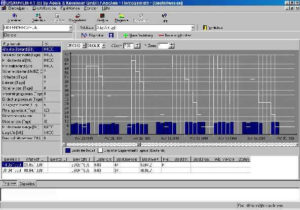

IT facts

DISKOVER is programmed in C++ and runs as a client on all Windows platforms. The central database server (e.g. Oracle, MS-SQL) communicates with the leading ERP system via a standardized interface. The client and server must be configured depending on the data volume: The minimum requirements for the system are an Intel Pentium III processor, 64 MB RAM, 10 MB hard disk space for the client and 200 MB free disk space on the server. The server is designed as a WindowsNT/2000 server.

Track record

By using DISKOVER, Abels & Kemmner has so far achieved two goals at over 40 companies that are actually contradictory: They increase the degree of delivery readiness and reduce stock levels at the same time. 82% of the companies were able to save at least 15%, 32% were even able to save more than 25%. The largest cluster with 43% of companies saved between 20 and 25%. However, it should be emphasized that DISKOVER as software alone is not a panacea. Rather, it is important that the know-how about scheduling procedures is applied in day-to-day operations. This always requires initial data preparation and detailed analysis of the product portfolio as well as intensive training of the dispatchers. In addition, operational practice should be reviewed at regular intervals even after the introduction of DISKOVER.