Reengineering

The world-famous luxury goods specialist Montblanc completed a multi-year restructuring project with resounding success: the work-in-process was halved, inventories were significantly reduced and the level of delivery readiness was considerably increased.

Time is money. Material that is being processed ties up capital. The faster an order can be processed, the faster it can generate sales. The more time an order takes to get from goods receipt through various production stages to the customer, the more material and capital it ties up. If you reduce the volume of material in work-in-process (WIP) accordingly, you can react faster with the same output and free up a considerable amount of the capital tied up in production. Fast response times open up the possibility of reducing stocks in finished goods warehouses. Ultimately, the supply chain is accelerated and streamlined in every respect. At Montblanc, the work-in-process was reduced by a remarkable 50% through purely planning measures. This required a complete reengineering of the supply chain.

Just a few years ago, Montblanc had a product range of less than 1,000 different models. Sales planning for Montblanc’s luxury goods was submitted monthly by the respective sales locations with country-specific split factors, recorded centrally and processed further for procurement and production purposes as well as for supplying the national warehouses. With around 1,000 product groups and well over 3,000 articles today, this planning method proved to be too complicated and too labor-intensive. The accuracy deteriorated increasingly. For this reason, the management initiated a reengineering of the entire planning process in spring 2001. “The management consultancy Abels & Kemmner developed a suitable conceptual approach for us to reorganize the entire supply chain, which we worked out together in several stages,” explains Burkard J. Kiesel, Director of Technology, Montblanc-Simplo, Hamburg. “As the aim was to optimize the supply chain from sales to procurement, all specialist departments, in particular sales logistics, production control, procurement and our IT department, were fully involved.” The result is a clear separation between strategic and operational planning. The planning input of the sales locations today concentrates on strategic planning with approx. 120 items to determine the “route” for production and procurement. Operational planning works exclusively at item level.

Clear portfolio responsibility

A replenishment system has been set up to supply the national warehouses, which is managed by the national logistics provider with clear inventory responsibility. At the same time, the role of planning and inventory management at the Hamburg site has been significantly enhanced: The Logistic Category Managers (central sales logisticians), who are organized by product area, are responsible for item-specific sales planning from the central warehouse. Its central task is to determine the future sales requirements per item as accurately as possible, taking into account all available information. The planning data determined in sales planning is then used by production control and procurement.

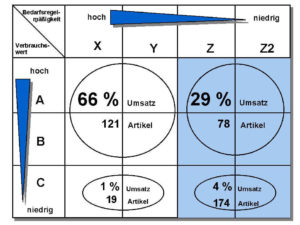

To implement this planning approach in practice, the items are first analyzed with regard to their planning capability using the “Diskover 4.1” scheduling optimization software. The system then determines the optimum planning procedures and parameters for the items identified as predictable. The easily plannable AB-XY articles (approx. 30% of all articles) already account for 66% of sales and more than 75% of annual production capacity. Diskover forecasts the future planned requirements for these items and transfers them to the SAP system’s Sales and Operation Planning (SOP).

The launch went according to plan. However, the first test runs showed that “the quality of our master data, e.g. replenishment times, rounding factors and minimum lot sizes as well as the current article status still needed to be revised,” says Burkard J. Kiesel. Added to this was the necessary employee training: “Initially, we significantly underestimated the time it took to familiarize our employees with this new approach. Necessary personnel changes cost valuable time and required a sure instinct,” says Kiesel.

Central planning tool

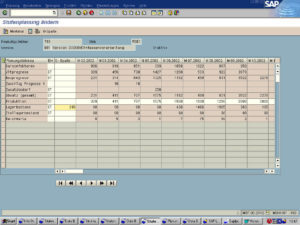

The SAP R3 SOP planning table was specially adapted as a central planning tool for coordination with production program planning: Based on the expected sales, the production and procurement quantities are initially planned on a rolling monthly basis, taking into account the capacity utilization of the affected workstations and machines along the supply chain and synchronized with demand. If there is a risk of capacity overload in a given period, necessary smoothing measures, e.g. bringing forward partial requirements quantities, can be recognized and planned in advance in the SOP tableau.

Production control and procurement planning will also use the SOP planning table in future: based on expected sales, they can plan production or procurement quantities in good time or order partial quantities earlier, taking into account the capacity utilization of the workstations and machines concerned along the supply chain. “This is particularly relevant for Montblanc, as we have a pronounced seasonal business, which makes this coordination and adjustment essential, especially to cope with the quarters with strong sales,” emphasizes Burkard Kiesel.

The key parameter in this reconciliation is the target stock level. Production control varies production and procurement quantities in such a way that capacity bottlenecks can be avoided and the target stock level is always available in future planning months. If there is already a recognizable capacity overload in a planning month, the planner can split the finished article quantities and bring them forward. In this way, the required quantities or partial quantities are shifted to other months and an impending capacity bottleneck is avoided. In future, Montblanc’s main suppliers (e.g. for leather) will also be included in this coordination so that capacity can be synchronized along the entire supply chain at an early stage.

The planning methodology presented was initially tested in two product categories. It has been used in all product categories since February 2003 and since then has ensured 98% delivery readiness to the national warehouses.

Kanban as card game art

Once the reengineering of the sales planning process had been completed, the project plan focused on ensuring replenishment of the central warehouse in Hamburg and reducing throughput times and stock levels in production. Due to the high level of vertical integration, the long replenishment times and the large and constantly growing number of variants, efficient value chains should be established by setting up decentralized organizational control loops that reduce the supply risk at all production levels to a minimum. However, the MRPII logic used, with its very high coordination effort, did not deliver satisfactory results. The previous approach lacked flexibility, particularly in the event of short-term fluctuations in demand for individual end products. In order to ensure delivery readiness on the market, excessive stock levels were necessary along the entire value chain up to the finished goods warehouse.

Improving delivery readiness

At Montblanc, the main lever for improving delivery readiness while simultaneously reducing inventories was the establishment of just-in-time final assembly and thus the shifting of inventories from the variant-rich end device to the variant-forming component level. The analysis of throughput and set-up times had shown that JIT production was possible without major costs. However, setting up JIT production requires a reliable supply of components and purchased parts for final assembly. For this reason, a central Kanban warehouse was set up before final assembly, which is served via several Kanban control loops from the upstream production stages. Suppliers are currently also gradually being integrated into the system. Thanks to the precise planning of the Ampel-Kanban system and the intensive and thorough preparatory work, the live switchover “took place without any major problems. All the preparations for the changeover were completed within just three days,” says a satisfied Peter Kluge, Head of Production Technology at Montblanc-Simplo and project manager for the Kanban project. For the first phase of the Kanban introduction, the SAP processes were redesigned so that they did not hinder the processes of the Kanban system with additional administrative work. The employees only opened a production order at the beginning of the production of a batch size and reported it back after completion. In the second phase, the Kanban system was linked more closely with the SAP system. SAP’s own Kanban control system was introduced for this purpose. Orders are now opened and closed automatically by scanning the barcodes on the Kanban cards.

Forward-looking planning

One of the major weaknesses in the dimensioning of a Kanban control cycle is the calculation using consumption from previous periods. In the dimensioning for Montblanc, on the other hand, the “future” in the form of rolling sales planning was used for the underlying consumption values. This was possible thanks to the previously revised, efficient sales and production planning chain.

This is where the fundamental reengineering process at Montblanc comes full circle. Today, MRP carries out the re-dimensioning of each individual item as required or at regular intervals using an SAP ABAP programmed on the basis of Abels & Kemmner’s special Kanban calculation system. With the help of this Kanban calculation system, the calculation of the yellow and red areas of the Kanban boards as well as a simulation of the capacity situation of the individual production areas were carried out at the same time for the dimensioning of the control loops, in addition to the currently required number of Kanban types per article and control loop. “This simulation determines the maximum and minimum number of setup operations required per time unit and compares these with the existing capacity situation,” explains Dr. Götz-Andreas Kemmner, Managing Director of Abels & Kemmner. In addition, the storage space required for the Kanban items is dimensioned by calculating the minimum, average and maximum storage space required per item and Kanban warehouse over time. At Montblanc, this data ultimately formed the basis for the procurement of sufficiently large Kanban boards and shelving systems.

The result counts

The reengineering project at Montblanc resulted in a halving of the work in process, a 48% reduction in inventories and, in particular, a significant increase in the delivery readiness level to 98%. For Montblanc, the investment in this reengineering project will therefore pay off not only through lower costs and more efficient production, but also through more satisfied customers.

Montblanc

Today’s global brand Montblanc celebrates its 100th anniversary in 2006. Birthday. The classic in the range, the Meisterstück fountain pen, dates back to 1924 and has since become a cult object. In 1998, the writing instrument manufacturer Montblanc-Simplo GmbH moved into the new production and administration buildings in Hamburg-Eidelstedt. Over the last ten years, Montblanc has developed into a luxury brand. The product range also includes leather goods, watches and other lifestyle items. The company has 16 distribution and production companies worldwide. Today, there are 200 Montblanc boutiques worldwide and over 8,000 sales outlets in 70 countries. The President and CEO is Norbert A. Platt. Around 1,800 employees currently work for the company internationally.

Abels & Kemmner

Abels & Kemmner GmbH, Herzogenrath/Aachen, was founded in 1993 by the engineers and economists Dr. Helmut Abels and Dr. Götz-Andreas Kemmner. The company focuses on streamlining value chains (supply chain optimization) for series and variant manufacturers as well as wholesalers. Abels & Kemmner deals with the design and optimization of order processing and logistics. The second focus is on restructuring and earnings enhancement projects.

Results in brief

- Planning method changed

- Disposition planning optimized by linking SAP R3 (SOP) with Diskover 4.1

- Over 75% of annual production can be forecast

- Final assembly switched to JIT

- Supply control of final assembly converted to Kanban

- Kanban activated in three days

- SAP integrated into Kanban processes with a simple barcode interface

- Finished parts warehouse dismantled

- 98% delivery readiness guaranteed

- 48% of the existing inventory value at the start of the project was reduced

- Work-in-process reduced by 50%