Konrad Ernst (SCHOTT Rohrglas GmbH, Mitterteich)

Bernd Reineke (Abels & Kemmner GmbH, Herzogenrath)

It is possible to keep stocks of finished products low and at the same time achieve a high level of delivery readiness of over 95% without significantly changing the production process. A joint project team from Abels & Kemmner and SCHOTT-Rohrglas GmbH was able to prove that this also applies to glass production, where melting tanks cannot be switched on or off “on the fly” and the downstream production steps cannot be converted “on demand” at short notice.

In logistics and production, every industry has its own specialties. As a process manufacturer, SCHOTT-Rohrglas GmbH, one of the world’s leading manufacturers of special glass tubing, has special requirements for inventory management. The continuous production process is characterized by high set-up costs, high energy costs and the highest demands on process and product quality. There are strict limits to flexibility in terms of batch sizes and capacity utilization. The production sequence of the articles, which are divided into 16 product groups, is also subject to strict technological rules that offer little scope for planning. Fluctuations in sales have a direct impact on delivery readiness and stock levels: When sales increase, the capacity limits are quickly reached, which can immediately lead to an impairment of delivery readiness for items with low stock levels. Falling sales cause an increase in inventories due to the continuous production process. The melting capacity of the tanks can only be reduced at considerable expense in terms of time and money. On the other hand, these production capacities may not be available when sales pick up again.

SCHOTT-Rohrglas therefore commissioned Abels & Kemmner GmbH to set up a systematic inventory and delivery readiness management system with the aim of achieving the target delivery readiness levels and reducing inventories to a level in line with the market, taking into account the technological constraints.

Abels & Kemmner’s process system, which has proven itself in many supply chain projects, provided for a bottleneck analysis and article structuring according to ABC and XYZ codes, as well as a concept phase tailored to the use case with simulation of the planning and scheduling procedures in question and subsequent implementation in the operational business processes.

The project team was made up of representatives from logistics. work preparation, sales and shipping from SCHOTT Rohrglas as well as industry and project experienced consultants from Abels & Kemmner. In the first step, the business processes of order processing, scheduling, production planning and shipping were analyzed and potential improvements were identified and documented. During a workshop, the project team members discussed this potential and developed the relevant fields of action. As a result of the bottleneck analysis, initial objectives for future processes and the SAP R/3 system in use were available in addition to the specific potential for improvement.

Fields of action

The bottleneck analysis resulted in the following areas of action in particular in order to link the value creation processes much more closely to market demand and thus reduce capital-binding and sometimes – due to indeterminable demand – high-risk finished inventories:

- Optimize scheduling support in SAP,

- Development of rolling sales planning,

- Integration of the new production and capacity planning into the new planning process,

- Design and optimization of order processing.

The article structuring according to ABC and XYZ criteria carried out in parallel to the business process analysis yielded the following results:

- High-turnover items (AB) with consistent consumption (XY) account for only a small proportion (3%) of all items.

- These items account for only 28% of the total stock, while over 70% of the stock is made up of items that only flow out irregularly and account for a small proportion of sales.

- More than half of the items did not move at all during the period under review (NN), but account for a significant proportion of the inventory volume.

The results of the ABC/XYZ analysis showed that the methods used for planning and scheduling did not meet the requirements of technology and engineering on the one hand and market requirements on the other. For this reason, the planning procedures in the second phase of the project, the concept phase, took center stage.

Stockpiling strategies

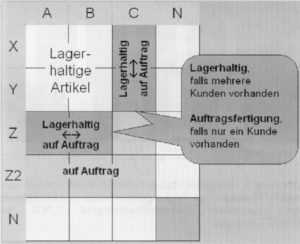

First, the stockpiling strategies were defined using the ABC/XYZ criteria. As only the AB/XY articles are regularly consumed and, due to the high proportion of sales, also quickly flow out of the warehouse again, it was decided to stockpile these articles in future. AB/Z and C/XY articles that are ordered by several customers and are therefore of strategic importance will also be produced in stock in future, while all other articles will only be produced to order (see Fig. 2).

Work preparation and production control

All items that are not in stock may only be produced in the required quantities, i.e. no stock may be built up, even if there is excess capacity. These are to be used exclusively for items in stock. If the inventory range of stocked items reaches twice the replenishment time, it should be checked to what extent maintenance-related downtimes can be extended in order to avoid excessive stock build-up in any case. Work preparation and production control in particular are now responsible for implementing and complying with these rules.

Simulation of planning and scheduling processes with DISKOVER

The DISKOVER inventory management and simulation tool from Abels & Kemmner was used to control and determine the average stock levels and safety stock levels of items in stock. Initially, only one type of glass was considered, namely DURAN®, which is used for technical glass, in order to gain initial experience with a few items and to verify the procedure for the remaining glass types.

DURAN® products are manufactured periodically, as the tools are changed in a specific sequence at the exit of the melting tank. These tools can only ever produce certain diameter and wall thickness ranges, meaning that an article can only ever be produced when the tool is in use again. To bridge this time interval, items in stock must be stocked at a correspondingly high level; this period is known as the stocking time (see Fig. 3) and is one of the main MRP input variables for the simulation.

In the simulation with DISKOVER, various planning and scheduling procedures are calculated for each item on the basis of historical data in order to obtain the best procedure with the optimum parameters. Further input variables for the simulation are the desired target delivery readiness levels, batch sizes and replenishment times. The achievable savings potential can be determined on the basis of the simulated average inventories and the simulated delivery readiness levels.

As with all simulation projects, various scenarios were defined to determine the influence of different input variables and processes. Since SCHOTT-Rohrglas uses SAP, a special scenario was calculated in which only planning and scheduling procedures were used that are also provided by SAP in order to determine the optimization possibilities both with and without further software investments.

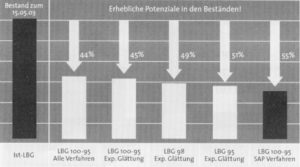

The results of the simulation runs with and without additional DISKOVER features showed that inventories can be reduced by almost half with the use of new planning and scheduling procedures (see Fig. 4). In all scenarios, the degree of delivery readiness was significantly improved to an average value of around 95%. For SCHOTT-Rohrglas, the simulation result of the SAP process was particularly pleasing: here, too, the inventory can be reduced by a good 50%, with an average simulated delivery readiness level of approx. 93% being achieved. An additional investment in DISKOVER for daily scheduling is therefore only necessary if the degree of delivery readiness is to be further increased under the given parameters.

Conclusion

Even in the process industry, where flexibility is severely limited and characterized by technological constraints, intelligent planning and scheduling procedures and demand-oriented stockpiling strategies can lead to considerable savings. Project members and the management of SCHOTT-Rohrglas were surprised by the amount of inventory reduction potential. Work is currently underway to implement the results quickly.