by Erich Kiltz1 and Dr. Bernd Reineke2

Change processes in the range of services also have an impact on the organizational form. Especially when a company develops from a component supplier to a solution provider. illbruck was looking for the ideal organizational form for this. Together with Abels & Kemmner, an organization tailored to this new orientation was developed. With the help of the bottleneck and value stream analysis, the requirements for the realignment were quickly worked out and presented to the management as feasible concepts. Now it’s time for implementation.

As part of the general wellness trend, the bathroom in the home, which has mostly been neglected up to now, is gaining in importance and is increasingly being designed holistically and developed into an individual feel-good and relaxation space in the home. illbruck Sanitärtechnik recognized this trend early on and made the transition from a supplier of individual components such as bathtub supports and base plates to an integrated problem and system solver. However, there was potential for optimization in the organizational form. Before a customer places an order, they first want a solution for the bathroom they want to design. Ideally, he uses the illbruck bathroom layout program together with the sanitaryware dealer by sketching his bathroom with the correct dimensions and drawing in the preset bathroom components. After transferring the data to the illbruck order processing department, an offer can be submitted to the customer on this basis within a short time.

So much for the ideal case. However, this is only used in very few cases. The reasons for this are, on the one hand, the necessary familiarization with the bathroom layout program and, on the other, the fact that special installation situations are not so easy to reproduce and require the design components to be adapted. For this reason, a quick hand-drawn sketch is often faxed over with a request for a quote. The task of order processing is then to implement the sketch itself in the bathroom layout program; the missing information must be requested from the customer and added.

This was not enough for the management. Customer service should be a top priority. The customer should be advised. Taking the special bathroom layout into account, he should be offered the ideal solution with design variants. In addition to the required components, supplementary products such as shelving systems or shower canopies with integrated lighting will round off the range.

But even with these individual solutions, the usual speed with which an offer is prepared is expected. At the same time, order processing must not be held up by these procedures and the production and procurement process must not be impaired. The previous organization could no longer meet these requirements, which is why the management decided to work with Abels & Kemmner to change the future organization to focus on customer orientation and complete bathroom offers.

Even during the initial discussions, it became clear that although the interests of production and sales both had the profitability of the company as their goal, their ideas of how to achieve this were very different. For the production department, which also creates the technical designs for the customer-specific offers, the focus was on optimizing costs and streamlining processes. Sales and marketing saw the improvement of market presence and consulting expertise as the main focus and called for the establishment of a Customer Competence Center.

As part of a bottleneck analysis, the existing organization and processes were first documented and examined using value stream mapping. This allowed uncoordinated processes and inconsistencies in procedures to be quickly identified and, where possible, eliminated using ad hoc measures. Breaks in the system landscape were also evident where interfaces were present that were characterized by manual data transfer. The majority of the throughput time through production was due to process-related drying times, which make it impossible to cycle the material.

Due to the low level of automation, standard products could hardly be produced more cheaply than customized products, which tempted customers to choose the slightly more expensive but customized product. Due to the increasingly high proportion of individual solutions, the products and processes can only be standardized to a limited extent; automation approaches are not worthwhile due to the low quantities of standard products.

The analysis of the quotation and order processing revealed that too many departments and people were involved. This led to long processing times and friction losses with sources of error in the interfaces. Until now, there was no electronic filing system for processes that could be called up anywhere, which led to long idle times and corresponding walking distances for inquiries.

The aim of the new concept was therefore to eliminate the inconsistencies in the processes, to convince the customer with fast response times on the one hand and with strong consulting expertise on the other. The different requirements of standard and customized products should also be taken into account.

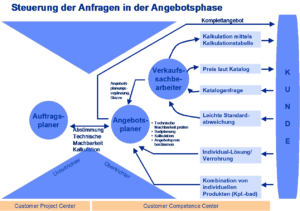

The Customer Competence Center was therefore established to process inquiries and prepare quotations, which can handle the majority of customer inquiries and orders independently, without the involvement of other departments. Only special customized solutions still require coordination of technical feasibility and costs (see illustration).

While the interface between production and sales is quite simple for normal component sales, communication between production and sales must be redefined for integrated offers in order to avoid frictional losses and delays.

There are two teams within the CCC: the sales clerks and the quotation planners.

The sales clerks are able to offer standard products and minor customizations, incl. calculation and pricing without any queries. This eliminates interfaces, time wasters and sources of error, and the customer has just one contact person who can answer all their questions.

The quotation planners are involved when the desired products are major adaptations of standards or new designs. You plan the bathroom with the support of the bathroom layout program, create sophisticated 3D visuals and create the calculation for pricing. They consult with their colleagues in production order planning to clarify technical feasibility and estimate costs. The order planner also integrates standard components into complete bathroom plans, which are delivered to the customer as part of a complete offer.

This organization means that the CCC group is decoupled from technical order processing. You can concentrate on the customer’s requirements and put forward ideas and suggestions without interrupting the operational process.

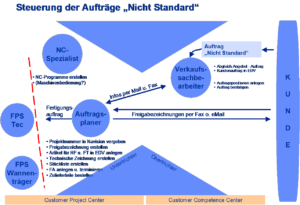

Production planning only becomes active once the customer order has been received and can be dispatched as part of scheduling and capacity planning. However, before production is released, the order planning department has the bathroom layout approved by the customer by sending the drawings to the customer by fax or email and receiving them back signed. All further steps are handled by the production department until the products are delivered to the customer. The CCC is therefore not burdened with operational issues and can concentrate fully on processing inquiries and advising customers.

1 Production manager at illbruck

2 Managing Director Abels & Kemmner