By Uwe Peters and Dr. Helmut Abels

More and more customers are reducing their stocks and using external wholesale warehouses. At the same time, they want to reduce the number of their suppliers to just a few and expand their product range to cover the entire range if possible. Of course, a high level of readiness to deliver and favorable prices are still a prerequisite. Wholesalers can only achieve this if they take a close look at their product ranges from a strategic perspective.

This is also the case at Widex Peters GmbH, headquartered in Düsseldorf: Widex Peters supplies screws and nuts in a main segment with a wide range of dimensions, material grades and surfaces in accordance with DIN or drawings. Over the years, the product range in this segment has grown to around 36,000 items due to the constant addition of new products. Inventory volumes and stock clearance developed accordingly. Efforts to maintain the usual high level of delivery readiness became ever greater. At the same time, the proportion of partial deliveries and short-term procurements from more expensive alternative suppliers increased.

To put a stop to this development, the retail company launched a project to optimize stock levels. However, the aim of this project was not to achieve a general reduction in stock levels, but rather to restructure the existing stock range in such a way that maximum delivery readiness to the customer can be ensured, taking into account the financial and local conditions.

Sales classification confirms Pareto principle

The article master data and the transaction data (quantity and value-related inflows and outflows) from the last two years were available as a database. This data was also considered representative for the near future (2-3 years). The first step was to structure the articles according to sales classes using ABC analysis. It was noticeable that around 9,000 articles had no sales at all in the period under review. These were therefore separated out immediately and excluded from further consideration with the aim of reducing the existing stocks as quickly as possible. The analysis of the remaining articles produced a nice rendition of the Pareto principle:

- 16% of the articles (A articles) generate sales of 80%,

- 42 % of the articles (A articles and B articles) have a turnover of 95

- 58% of the articles (C articles) therefore only generate a turnover of 5%.

The distribution of inventories across the article structure was similar to their sales shares, but with a slight shift in favor of C articles (12%). Drawing parts, i.e. screws based on customer designs and surface-treated items, were predominantly not stored.

High irregularity of demand prevalent

A further classification of the articles according to predictability or uniformity of demand patterns (XYZ analysis) clarified the actual planning problem:

- only 2% of A and B articles are X articles, i.e. articles with a consistent demand,

- 45% are Y articles with already significant fluctuations in demand and

- 53% are Z-articles with extremely high fluctuations and high irregularity of demand; in the case of C-articles, X-articles were not detectable and Y-articles only to a small extent. In the period under review, articles with a high degree of irregularity in demand through to articles with one-off demand clearly dominated here (96%)

Assortment strategy

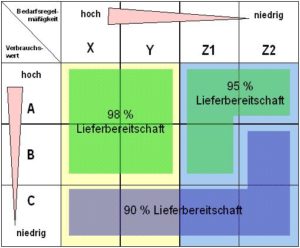

Following these preliminary analyses, the required stock levels for the individual article classes were determined using the strategic inventory planning program “Diskover” from Abels & Kemmner. Based on this, the stock range was determined, including the definition of corresponding delivery readiness levels. The calculation was carried out for three different degrees of readiness for delivery (90%, 95%, 98%). Contrary to the previous philosophy, items with surface treatment were also included in the analysis. Due to the lead time required for subsequent treatment, this was assumed to be the main reason for previous partial deliveries. The stock levels determined were compared with the inventory levels as a benchmark for the actual situation: For the X-items in the A and B sales classes, even with a 98% delivery readiness level, a total stock reduction of 45% compared to the inventory level was determined. For the Y-items, the total stock levels determined at 98% readiness for delivery corresponded approximately to the inventory levels. In some cases, however, considerable differences between target and actual stock levels were identified for specific items. This was also confirmed for items in the C sales category.

With this result, the scheduling strategy for these parts was already fixed: consumption-oriented scheduling with a parameter setting for 98% delivery readiness. If the customer demand is based on the sales share of the articles, 65% of the demand requirement can already be satisfied with 98% delivery readiness. In the case of Z-items, there were major differences in inventory development between the sales categories: As the degree of readiness for delivery increased, stocks of AZ articles grew disproportionately, reaching almost three times the current stock volume at 98%. In particular, stocks of surface-treated items increased to the level of the current stock volume.

In the case of FC articles, the increase was not quite as significant due to the lower overall volume; while the cumulative stock levels at 95% delivery readiness level were still roughly the same as the inventory level, the amount doubled at 98% delivery readiness level. The stock trend for CZ articles was similar to that for B articles. With a delivery readiness level of 98%, inventories here also reached around the same level as annual sales. In order to arrive at a more differentiated view of these article spectra, a further classification of the Z articles per sales class was carried out according to zero-period share. The number of months per year in which an item was not required was checked. This subdivision provided information on the proportion of each item influencing stock levels: Items with a zero-period share of up to five periods per year were designated as Z items. Stocks of these items rose by around 30%, with the delivery readiness rate increasing from 90% to 95%.

Articles with a zero-period share of six periods and more were designated as Z2 articles. As the proportion of zero periods increased, so did the rate of increase in inventories as the degree of readiness to deliver increased. 90% of BZ articles and 99% of CZ articles belong to this Z2 category.

Differentiated product range strategy required, especially for Z-parts

The following assortment strategy was therefore defined for Z articles: Due to their high demand share, old AZ articles are kept in stock with a delivery readiness level of 98%, despite the considerable increase in stock, so that an acceptable average stock turnover can still be ensured even with this increase in stock. The BZ and CZ articles are divided into Z1 and Z2 articles. The Z1 articles are stocked with a delivery readiness level of 95%, while the Z2 articles are to be largely reduced due to their high sporadicity (see chart). Two measures are being pursued to ensure that customers can still be supplied with these items at short notice: Sales is requested to work more intensively with customers on procurement planning for these items in order to obtain information on the demand for these items at an early stage; at the same time, cooperation partners are sought on the procurement side in order to bundle small and sporadic procurement quantities in particular and thus enable cost-effective warehousing and rapid procurement of these items.