Product and variant diversity determine business in the German baked goods industry. The customer-oriented large assortment eats up earnings if the product portfolio is not regularly analyzed and optimized. Kronenbrot started out as a small country bakery in 1865. The success of the fifth-generation family business is based on tradition and constant innovation. What Franz Joseph Mainz started as a founder in Würselen near Aachen, his grandson Franz laid a forward-looking foundation in 1915 under the name Kronenbrot.

Today, the company is one of the most modern industrial bakeries: Baked goods for North Rhine-Westphalia (NRW), Rhineland-Palatinate, Belgium and the Netherlands are produced at the Würselen near Aachen, Cologne and Witten sites. Today, Kronenbrot is the leading supplier of bread and baked goods in NRW. Around 3,000 food retailers and bulk consumers are supplied with fresh baked goods every day.

New innovations are constantly enriching the range of baked goods for the market: in addition to bread toast and rolls, cakes, pastries and stollen, the Kronenbrot range also includes European specialties such as ciabatta and ciabatta rolls, flatbread, baguettes, baguette rolls, brioche and croissants.

Kronenbrot was one of the first bakeries to stop using preservatives more than a decade ago. This is possible because the grocery stores are supplied with freshly baked bread straight from the oven in the early hours of the morning.

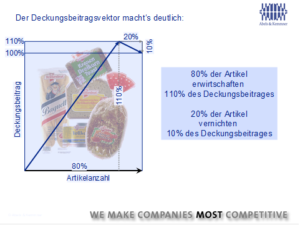

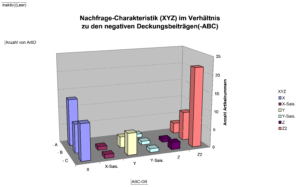

For Kronenbrot, this aspect of freshness makes it impossible to have a finished goods warehouse to cushion the fluctuating market demand compared to production: yesterday’s goods can no longer be sold today. Every day, around 600 items have to be produced and baked in sync with market demand. In some cases, delivery and production batch sizes only correspond to very small quantities, the production conditions of which have little to do with a large bakery. As is usual for most companies, it was found that the Würselen plant also generates around 80% of its sales with 20% of the articles being AB-XY articles that are easy to plan. This contrasts with a group of over 25% of articles (non-forecastable CZ2 articles) that together generate less than 5% of sales. This diversity of variants with small batch sizes increases the process costs associated with handling small quantities. There is a risk here that certain items can no longer be produced economically.

As part of a project to analyze the potential of the Würselen plant, the product portfolio was therefore subjected to a critical review. Kronenbrot KG commissioned Abels & Kemmner to do this. The aim was to streamline the current product range from a business and sales perspective.

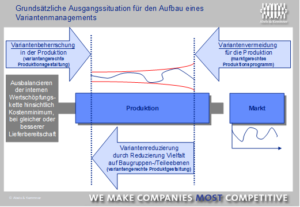

From a logistical point of view, a large number of variants should be avoided. However, if it is present, it is important to check whether and how it can be reduced.

From a logistical point of view, a large number of variants should be avoided. However, if it is present, it is important to check whether and how it can be reduced.

In order to start at the right point, the contribution margins of the articles are analyzed, both in terms of absolute values and unit contribution margins. Depending on the sales opportunities, articles with negative contribution margins should be

- their contribution margins can be improved,

- be deleted,

- expire,

- be replaced by substitute products with higher contribution margins or

- be procured externally.

With these articles, money is added to each item produced.

Storage options pose particular problems. It makes more sense to replace the item than to optimize its cost. Negative contribution margins were also found in the analysis for high-turnover items. Here, however, the options for action are more limited. Products of this type can only be improved in their contribution margins or replaced by substitute products with higher contribution margins. External procurement, deletion or phasing out would inevitably lead to major cuts in the company.

Calculate with the right numbers

The contribution margin analysis requires differentiated cost accounting in order to calculate the correct contribution margins and uncover the cause of negative contribution margins. In many cases, the contribution margins must first be calculated correctly, and this also applies to the data from the ABC-XYZ analyses.

The use of substitute products as an alternative for Kronenbrot does not necessarily require different recipes. Sometimes it is sufficient to standardize packaging or to implement packaging variants in a simpler way. A positive contribution margin can be generated by streamlining marginal variants.

Where end products or end product variants cannot be dispensed with, attempts must be made to reduce the variety of articles at upstream production levels. Assemblies are standardized for this purpose. The “platform strategy” familiar from the automotive industry pursues precisely this goal of producing a wide range of variants from just a few assemblies. This strategy is more difficult to pursue in the production of baked goods and, where it is possible, such as in the case of fruit Danish pastries, has already led to a large number of variants.

Ultimately, the remaining variant diversity with a negative contribution margin must be further optimized in production. Strategic levers for this at Kronenbrot are, for example, special baking lines for small quantities, which are constantly being optimized.

Outlook

Outlook

Buying habits are increasingly changing, also under the influence of new product ideas from Kronenbrot. Optimizing the product portfolio is a task that should be carried out at least once a year for baked goods. In order to be able to carry out portfolio optimization systematically in the future, the next step is to automate the necessary data selection, preparation and processing to a greater extent. As a traditional family business, Kronenbrot has a special responsibility towards its employees. From this perspective, product portfolio optimization is an important step towards securing jobs in the face of growing competition.