Consistent market orientation with pull system at Hansgrohe

Ulrich Jaeckle

Hansgrohe AG, one of the few global players in the sanitary industry, is currently optimizing its supply chain processes. The “Logistics 2010” project is of extraordinary strategic importance for the company. The focus here is on optimizing the entire value chain. In an initial sub-project, production and procurement were to be optimized and consistently aligned with market requirements. The first results are now available: Thanks to the consistent implementation of the pull system, from now on no order will be triggered without a demand requirement, which creates inventory security. In addition, the potential for reducing inventories of raw materials by more than 30 percent has an enormous impact on liquidity.

Summary

Stock reduction by over 30 %

– consistent market orientation with the aid of the Pull System at Hansgrohe

Hansgrohe AG, one of the few global players in the sonitary branch, is currently optimizing its supplychain processes. The project “Logistics 2010” has an extraordinary strategic meaning for the company Priority is given to optimizing the entire value added choin. In the first part of the project the areas of production and procurement have been optimized and consistently been adopted to morket requirements. First results are evailable: to consistently opply the Pull System, no order has been launched without a specific demand which has lead to stock security. Furthermore, the potential to reduce the stock of row material by over 30% has increased liquidity tremendousty.

Project goals

The objective of the project was clearly defined from the outset: To react flexibly to the increasing demands of the market with short response times. The aim is to keep stocks as low as possible without compromising the delivery service or increasing process costs.

In plain language, a consistent focus on the market means that products in demand must be available at short notice and that no procurement or value creation can take place without demand. This requires finely tuned process steps within the company, but also across companies and suppliers.

The tasks at hand were tackled in parallel in several teams: The process team was responsible for designing the process-oriented production lines. The product team was to convert the company’s internal material flow to consumption control. The procurement team had the task of optimizing procurement planning and integrating suppliers into the procurement process.

Inventory analyses

Inventory analyses

With the aim of achieving positive effects in the short term, a two-stage approach was adopted in the area of procurement logistics. The first step was to analyze and change the procurement planning. By optimizing scheduling parameters and logistics sizes, it is often possible to reduce inventory levels with little effort.

The second step was to integrate the suppliers into the procurement process in order to make the overall process more efficient and flexible. The suppliers include small and medium-sized companies in the vicinity of Hansgrohe’s headquarters in Schiltach as well as numerous companies spread throughout Germany. Other suppliers can be found in Europe and Asia.

In many cases, the players used tried-and-tested methods and procedures. These included.

- ABC/XYZ analyses,

- Stock range and stock swamp analyses,

- Recording of current procurement processes and supplier integration,

- Simulation of different disposition and planning procedures with variation of certain parameters (e.g. forecast parameters) and logistical control variables (e.g. minimum order quantities, delivery times).

An initial review of the current procurement processes and existing supplier relationships showed that Hansgrohe AG is already operating at a high level. The procurement processes were mapped and supported by the SAP system throughout. Framework agreements (volume contracts) with delivery call-offs already existed with many suppliers. This was also already an integral part of the SAP processes.

The “Lextra” supplier information tool developed by Hansgrohe proved to be very efficient. This is an Internet platform where suppliers can access all the necessary and supplementary information. The information includes long-term requirements planning for materials, framework agreements and short-term delivery call-offs. This means that suppliers receive their orders without paper or faxes.

Some suppliers also use this source of information for automatic data transfer to their own merchandise management system and can save time, effort and error costs in this way.

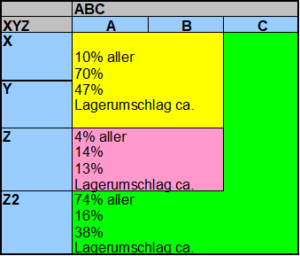

The second step involved an ABC/XYZ analysis for the purchasing materials at the West plant (Schiltach). The data required for this was provided by specially developed reports from the SAP system, which were analyzed using external tools. The observation period was twelve months.

The XYZ analysis was carried out on a weekly basis. While X and Y articles show a relatively even consumption in the past, Z articles have an irregular to sporadic stock-out character. In addition, in the XYZ analysis, items that were not in demand for more than six months were specially marked. These Z2 items are primarily new or discontinued purchased materials that are to be treated separately.

The results of the ABC/XYZ analysis show a classic picture: While it is possible to keep inventories in the AB/XY area low in relation to sales, inventories of sporadically required items (Z2 items) and low-value C items are too high, which is reflected in low inventory turnover. (Fig. 1).

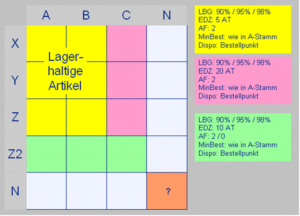

The range of coverage analysis illustrates the way the planners work (Fig. 2): High-quality A and B parts are stocked at lower levels and have shorter ranges, while C parts are stocked at higher levels, thus saving administrative effort.

Simulation and optimization

Based on these findings, the next step was to define the parameters for the simulation runs using the Diskover optimization tool¹.The aim was to achieve a high stock turnover for the high-quality A and B articles wherever possible. For this purpose, a stocking period of five working days was selected, i.e. the requirements of five working days were combined in the order quantity calculation.

A stocking period of 20 working days was selected for the low-value C-items, which only has a minor impact on stocks, but should keep the administrative and physical effort in both purchasing and logistics to a minimum. The sporadically consumed Z2 items were also taken into account in the simulation, although these items should be procured on an order-related basis in future due to the higher inventory risk. All articles were simulated with three different degrees of readiness for delivery (90, 95 and 98 percent) in order to be able to assess the achievable degrees of readiness for delivery and to determine the effects of the degree of readiness for delivery on stocks (Fig. 3). The simulations were carried out both with the forecasting methods available in Diskover and, to a limited extent, only with the methods available in SAP, which meant that the distribution-free methods were excluded.

The results of the various simulation runs revealed stock reduction potentials of up to 47 percent. The delivery readiness rates for items that will be in stock in the future ranged from 91% to almost 96%. The high delivery readiness levels were achieved with the distribution-free procedures in Diskover, but the SAP procedures also produced satisfactory results.

The SAP process with a target delivery readiness level of 95% was therefore chosen as the preferred option, which still meant a stock reduction of around 34%.

Following the analyses and simulations, the team immediately set about implementing the results. To this end, the MRP procedures for selected stock items in the SAP system were converted to forecast-based reorder point procedures and the necessary planning parameters, as calculated by Diskover, were entered. The standard settings of the reorder point procedures in SAP were modified in Customizing so that the system also takes the current requirements into account in the procurement calculation and, after deducting these requirements, the stock level is still higher than the reorder level.

Integration of suppliers

Integration of suppliers

As a result of the changeover, Hansgrohe AG is no longer stocking up so heavily on materials. With the reduction in minimum order quantities and replenishment times that Purchasing was able to agree with suppliers, the number of delivery call-offs is increasing compared to the past.

In order to prepare the suppliers concerned for these changes, the project team invited them to an information workshop at which the procedure in the Logistics 2010 project was explained in more detail and the effects on future call-off behavior were presented. Each supplier received a list of their articles with details of the changed settings. The suppliers once again confirmed the delivery deadlines and delivery flexibility agreed in the framework agreements, as these settings will continue to gain in importance for Hansgrohe, particularly due to the lower stock levels in the future, and are essential for successful implementation.

The response from suppliers was consistently positive. Their involvement in the project work at Hansgrohe offered the opportunity to influence future processes and gave a clear signal for long-term cooperation. Many suggestions were incorporated into the results of the project work and contributed to the overall success.

The conclusion of the supplier meeting included an outlook on future cross-company material flow concepts, including the integration of suppliers via Kanban. The project team took this Kanban connection as the next step towards further optimization, also in terms of reducing internal administration.

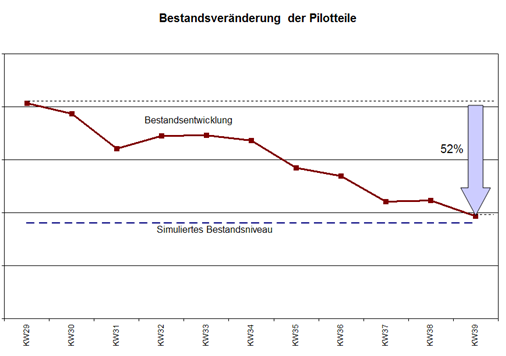

The success of the changes became apparent within a short space of time. Within ten weeks, the stock of pilot articles had already fallen by over 50 percent, meaning that the simulated target stock levels had almost been reached (Fig. 4). After further conversions, the total stock fell by over 15 percent within a short space of time.

With these positive results, material flow supplier integration is now being driven forward with the aim of further optimizing inventories and significantly reducing administrative costs in logistics and purchasing.

INFORMATION

Hansgrohe AG, based in Schiltach in the Black Forest, employs more than 2,800 people worldwide, a third of whom work abroad. The company, which in its 104-year history has earned a reputation within the industry as an innovation leader in technology and design, generated sales of 428 million euros in 2004 with its brands Axor, Hansgrohe, Pharo and Pontos (2003: 369 million euros) – an increase of 16 percent compared to the previous year. Hansgrohe AG produces in five German plants, in France, in the Netherlands, in the USA and in China. www.hansgrohe.com

The following consulting companies are involved in the project: Abels & Kemmner Gesellschaft für Unternehmensberatung mbH: Specialist in the field of supply chain optimization, supplier integration, kanban and inventory management.

ak-online.de

The Leonardo Group GmbH: Specialist for supply chain management with a focus on lean production, Kanban and flexible factory.

www.leonardo-group.com