The use of RFID technology must be carefully considered

by Dr. Bernd Reineke

Many companies are asking themselves whether the time has finally come to introduce RFID technology with the availability of the new Generation 2 tags or whether they should wait and see.

With any new technology, early adoption is always associated with risks on the one hand, but on the other hand there are always opportunities to achieve enormous competitive advantages. This also applies to the hyped topic of RFID. RFID technology actually offers everything logisticians can dream of: contactless reading of information without visual contact, decentralized updating of information directly on the product, automatic stocktaking at the touch of a button, automation of logistical procedures and manufacturing processes, huge savings potential, recognition of stock-out situations, and, and, and. All in all, there is huge potential for savings and enormous potential for business process optimization. And all this is now even more secure and flexible thanks to Generation 2 tags with additional frequency bands, faster transfer rates and less susceptibility to interference.

However, as with any investment in a new technology, the use of RFID raises questions about suitability and reliability, additional benefits and profitability. So before taking up the cause of RFID and declaring it a strategic business component, it is advisable to examine these questions in detail and, if necessary, test them in small pilot areas. It is not uncommon for poorly prepared restructuring – and this includes RFID projects – to lead to a cost trap, frustration and subsequent abandonment.

Of course, there are successful RFID applications that can be used as benchmarks. On closer inspection, however, they are often not transferable one-to-one to corporate logistics: Car immobilizers, access control (e.g. at ski lifts), animal identification, toll control. With all these solutions, humans can intervene manually in the event of problems (e.g. access control), or errors within a certain tolerance are accepted (e.g. toll control). But what if a reading accuracy of 96% is achieved in the logistics process during bulk detection (detection of many tags in one reading process)? If booking processes, e.g. in the ERP system, are linked to the reading processes, stock differences occur within a short period of time, leading to considerable disruptions in the logistics process. Without careful examination, you quickly run the risk of generating damage from planned benefits. So before you invest in the new technology, you need to check its applicability very carefully. The following procedure is recommended:

1. definition of the RFID application area

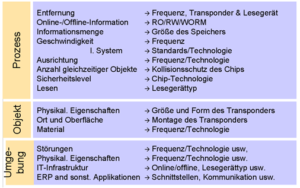

Identification of the processes, the affected products and the application environment with regard to the expected optimization potential and implementation options. There is potential for optimization, particularly in the automation of manual activities, the recording of mass data, error prevention and traceability down to the individual product.

2. definition of the technical specifications

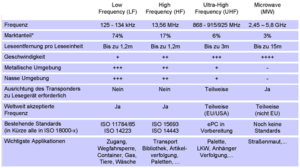

With the help of RFID experts, the right standards and hardware must be selected, taking into account environmental conditions, materials, quantity structure, connection to the company IT, tag cycles, etc. (see Figure 1). A decision must be made as to whether closed tag loops (i.e. reuse of the RFID tags) or open loops with loss of the tags should be selected. The latter can have a considerable influence on the achievable ROI (see point 4).

3. carrying out a feasibility study

Before the ground-breaking ceremony, pilot installations must be carried out in the actual environment in order to test the feasibility of using the selected RFID technology. In addition to the reading quality, compliance with the prescribed limit values for the effect on humans should also be checked here. The equipment required for these tests can be provided by the consultant or appropriate institutes. Only when the facts are on the table and feasibility has been proven can a decision be made on how to proceed.

4. profitability analysis

After estimating the potential savings to be expected through optimized processes, error prevention, traceability, etc., the investments to be made must be compared and evaluated. If cross-company processes are affected by the use of RFID, possible savings with the business partner must also be taken into account. However, the prerequisite for this is that the business partner contributes to the costs or rewards the added value accordingly.

5. preparation and application in a pilot area

In a small, manageable area, processes can be optimized and adapted with the use of RFID. This enables experience to be gathered at low cost and creates confidence for the subsequent rollout phase.

6. rollout to other areas/products

However, a structured approach alone is no guarantee of a successful technology launch. External support is highly recommended, especially when dealing with the diverse RFID technology for the first time, despite standardization, and the associated logistics and IT adjustments that are usually required. Bad investments can thus be avoided. And the project is usually completed in less time at a lower overall cost. In addition to the necessary technical know-how, particular attention should be paid to experience in optimizing internal and cross-company business processes when selecting experts. Ultimately, the main potential of the new technology lies in business process optimization, which should be approached as holistically as possible, i.e. with the involvement of suppliers and customers if necessary.

In addition, the introduction and implementation competence is also a decisive criterion. Choosing the right service provider is not easy, because you won’t find providers of this type like sand by the sea. Smaller, but highly specialized application consultants are ideal, as they can call on system houses and institutes in the competence network flexibly and on a case-specific basis, making it possible to compare and try out products from different hardware and software manufacturers. Abels & Kemmner is one such provider with more than 10 years of expertise in the use of barcodes and, more recently, RFIDs in internal and cross-company supply chain management. The focus is always on efficiency. This is usually achieved by synchronizing production with the market and thus increasing delivery readiness while at the same time reducing inventories. If this is possible – and according to all known studies this is the case for most companies – the introduction of automatic recognition systems such as RFID pays for itself within a very short time.