60% storage space saved through inventory optimization

For many years, Thermo Electron has concentrated on the core competencies of technology, product development and marketing of mass spectrometers and has gradually reduced its in-house production depth. However, this did not automatically lead to lean internal materials management. The company therefore commissioned supply chain specialist Abels & Kemmner to plan new logistics processes and support their implementation. Here are the results.

Short delivery times for customers from research, public institutions and industry also play a key role for highly specialized analysis devices. For this reason, Thermo Electron procured standard components and devices mostly on a customer- and order-neutral basis in order to ensure a high level of delivery readiness at all times. A large number of mechanical and electronic assemblies and countless individual parts were always kept in stock.

Following the outsourcing of the special workshop and vacuum technology in the 1990s, however, inventories of purchased parts, some of which were of very high quality and in large volumes, did not fall appropriately. The management therefore redefined the target: inventory values must be reduced by at least 40 percent from around five million euros to around three million euros. The fact that the new building, which was to be occupied at the beginning of 2005, also required this target from a purely physical point of view, as the storage areas were correspondingly tightly dimensioned during the construction planning phase, created a corresponding pressure to move. The challenge in this project was therefore, on the one hand, to maintain or ideally even increase delivery readiness and, at the same time, to drastically reduce stocks.

Right at the start of the project, it became clear that supplier integration would play a key role in the design of future logistics processes. In particular, they should support and help shape the changeover from the previous push system to the future pull system by taking over the stockpiling of large-volume and high-quality assemblies in particular. However, before the suppliers could be familiarized with the new structure, important preliminary work had to be done. These included:

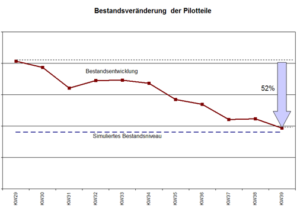

In just 10 weeks, Hansgrohe was able to reduce stocks of the pilot articles by 50%. The prerequisite for this was a detailed analysis of the stocks and simulation of the supply chain to optimize the logistical parameters Analysis of procurement parts using the ABC and XYZ methods,

- Volume analysis of purchased parts to estimate the required storage volume,

- Analysis of the appliance structure with regard to multiple part use and the possibility of combining them into so-called delivery kits, review of purchasing-relevant

- Logistics parameters such as replenishment times, minimum order quantities and price scales.

The first starting point was to create assembly kits

At the beginning of the project, the product structures had to be analyzed in detail using the parts lists up to the purchasing component level. The parts lists reflected the structure according to functional assemblies from a design perspective; aspects of assembly and parts usage were given less consideration. All fasteners such as screws, clamps, washers and nuts were included as individual items and were also procured and stocked individually. An initial starting point here was to create so-called assembly kits, such as the connecting elements required in the assembly process. In terms of the parts list structure, the assembly kits are therefore assemblies that are procured externally. This significantly reduces the number of individual parts that need to be procured, as well as the work involved in goods receipt or picking. Other examples of assembly kits are pump kits (vacuum pumps, hoses, connections, etc.) or tools for setting up devices at the customer’s premises (e.g. tool bag, screwdrivers, open-end and ring wrenches, ratchets, etc.).

Furthermore, the range of hand bearing parts was reviewed and adapted to current assembly requirements. Manual bearing parts are low-value DIN and standard parts that are required for practically every appliance. They are stocked at the assembly workstations and procured purely on the basis of consumption. Compared to other parts, the procurement and provision of hand bearing parts therefore involves very little effort.

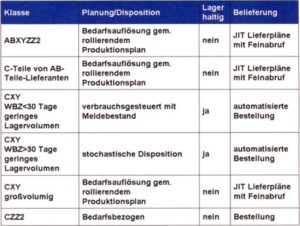

Once the product and parts list structures had been clarified, the stocking strategies for assemblies, assembly kits and individual parts could be decided. This was based on the ABC/XYZ analysis and the results of the volume analysis. The ABC analysis was carried out classically according to purchasing sales or according to manufacturing costs in the case of in-house production parts at 80 %. (A), 15 % (B) and 5 % (C) Share of sales. The XYZ analysis is an evaluation of consumption based on the coefficient of variation and provides information on the uniformity of parts consumption. While X and Y parts flow out of the warehouse relatively regularly, Z parts mainly show irregularities in consumption. The more uniform the consumption, the more reliably the components can be planned, and conversely, the more uneven the consumption, the more difficult it is to plan the parts. This was taken into account accordingly in the following analysis.

As can be seen from the table, it was decided that all A and B parts, regardless of consumption patterns and volumes, will in future be procured on demand and delivered just in time (JIT) by the supplier. If a supplier is already a JIT supplier because it delivers A or B parts, all other items from this supplier must also be delivered just in time. Large-volume C-parts are also just-in-time candidates if they exhibit X or Y consumption behavior. All other low-volume CXY parts must be stockpiled and procured according to consumption. The differentiation in the disposition of these parts, whether to be procured via reorder point procedures or stochastically via forecasts, depends on the replenishment lead time.

The necessary conversions of the SAP R/3 system were prepared by the SAP specialists at Abels & Kemmner GmbH and carried out in close coordination with the central IT department, which is based at Thermo Electron in the USA. The focus was on high transparency of the procurement situation, including traceability down to the individual appliance, as well as the most efficient handling of order and booking processes. The possibilities for simplification and automation contained in the SAP standard were perfectly utilized for this purpose.

The new processes and interrelationships, in particular the new just-in-time delivery, were documented and coordinated and trained with internal staff. This means that JIT parts can now be identified in the incoming goods department and transferred directly to the production area, which reserves separate staging areas specifically for upcoming assembly orders, without having to store them. However, coordinating the new processes with the suppliers was also an important step in successfully implementing the project results. To this end, the JIT suppliers were familiarized with the changes in individual meetings and, in particular, the flow of information between the companies was coordinated. The delivery schedules in particular were refined and optimized in several stages in collaboration with the suppliers.

The JIT suppliers were made fit in individual meetings

By the end of the initial project, the first fruits of success were already apparent: the value of the inventory fell by 46% within 7 months. The target stock level determined with the Diskover simulation tool from Abels & Kemmner, i.e. the stock of the remaining BOM items, is even more than 60% below the initial value. The number of active assemblies and components used in parts lists was reduced by 15 % for the basic appliances and by 11 % for the options, which are modules that can be used according to customer requirements. The move at the turn of the year and the associated changes were completed within a very short space of time. The new processes are currently being fine-tuned and consolidated.