PROCESSES – Inventory management

SCM Hansgrohe is polishing its supply chain with the “Logistics 2010” project. Measures such as supplier kanban and demand-driven procurement are bringing the sanitary specialist initial success.

Logistics is one of our core topics for the coming years. The “Logistics 2010″ project is of extraordinary strategic importance for Hansgrohe,” explains Siegfried Gänßlen, CFO of Hansgrohe AG, Schiltach. The global sanitary and bathroom specialist has grown strongly in recent years: turnover climbed from EUR 224 million to EUR 476 million between 1996 and 2005. However, growth also brought problems: Hansgrohe had to contend with rising inventories. The share of logistics costs also increased.

Hansgrohe therefore launched the “Logistics 2010” project back in January 2005 and initially ventured into its production and procurement. Hansgrohe was already operating at a high level here. The procurement processes were consistently mapped and supported by the SAP system and framework agreements with delivery call-offs were already in place with many suppliers. The company also had a powerful supplier information tool called “Lextra”. This is an Internet platform on which suppliers can access all the necessary and supplementary information. “But we had far too much stock from suppliers in our factory. We had to change that,” says Ulrich Jaeckle, Head of Purchasing/Logistics at Hansgrohe. The goal: to implement a pull system that is reflected from the customer to the supplier. The sanitary specialist received support from the consulting firms Abels & Kemmner Gesellschaft für Unternehmensberatung mbH, Herzogenrath near Aachen, and Leonardo Group GmbH, Munich.

Hansgrohe opted for a two-stage approach to procurement logistics. The first step was to analyze procurement scheduling and switch to consumption-based scheduling. Jaeckle: “By optimizing scheduling parameters and logistics sizes, it is often possible to reduce stock levels with little effort.”

Procurement on the test bench

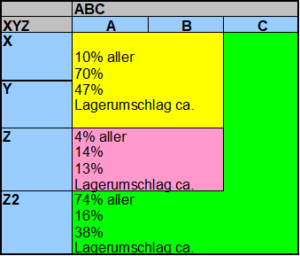

In an ABC/XYZ analysis, the company first scrutinized the purchasing materials at the Schiltach plant: Which items were important for production (ABC) and how accurate was their forecasting and planning (XYZ)?

The necessary data was provided by specially developed reports from the SAP system, which Hansgrohe analyzed using external tools. The observation period was twelve months. The XYZ analysis was carried out on a weekly basis. While X and Y articles show a relatively even consumption in the past, Z articles have an irregular to sporadic stock-out character. In addition, in the XYZ analysis, the articles that were not in demand for more than half of the 52 weeks were specially marked. These Z2 items are primarily new or discontinued purchased materials that are to be treated separately.

“The results of the ABC/XYZ analysis showed a classic picture: While we managed to keep inventories in the AB/XY area low in relation to sales, inventories of sporadically required items (Z2 items) and low-value C items were too high. This was reflected in the low value of stock turnover,” explains Jaeckle. A range analysis clarified the way the planners work: High-quality A and B parts were stocked at lower levels and had smaller ranges, while C parts were stocked at higher levels, thus saving administrative effort. An initial situation with plenty of potential for optimization. A simulation using the “DISKOVER” optimization tool from Abels & Kemmner GmbH was used to uncover these. Jäckle names the necessary parameters: “Where possible, a high stock turnover should be achieved for high-quality A and B articles. For this purpose, a cover period of five working days was selected, i.e. the requirements of five working days are summarized in the order quantity calculation.”

For the low-value C items, Hansgrohe chose a coverage period of 20 working days. This only has a minor impact on stocks, but should keep the administrative and physical effort in both purchasing and logistics to a minimum. The sporadically consumed Z2 items were also taken into account in the simulation, although these items should be procured on an order-related basis in future due to the higher inventory risk.

All articles were simulated with three different degrees of readiness for delivery (90, 95 and 98 percent) in order to be able to assess the achievable degrees of readiness for delivery and to determine the effects of the degree of readiness for delivery on inventories. The results of the various simulation runs revealed stock reduction potentials of up to 47 percent. The delivery readiness rates for items that will be in stock in the future ranged from 91% to just under 96%.

Successful implementation

“Following the analyses and simulations, the team immediately set about implementing the results. To this end, the planning procedures for selected stock items in the SAP system were converted to forecast-based reorder point procedures and the necessary planning parameters, as calculated by DISKOVER, were entered,” says Jaeckle, describing the further procedure.

The standard settings of the reorder point procedures in SAP were modified in Customizing so that the system also takes the current requirements into account in the procurement calculation and, after deducting these requirements, the stock level is still higher than the reorder level. As a result of the changeover, Hansgrohe AG is no longer stocking up so heavily on materials. With the reduction in minimum order quantities and replenishment times that Purchasing was able to agree with suppliers, the number of delivery call-offs is increasing compared to the past.

The success of the changes became apparent within a short space of time. Within ten weeks, the stock of pilot articles had already fallen by more than 50 percent, meaning that the simulated target stock levels have almost been reached. The total stock was reduced by over 15 percent within a short space of time following further conversions.

Connection via Kanban

The second step was to integrate the suppliers into the procurement process in order to make the overall process more efficient and flexible. Since the beginning of 2006, the company has therefore been integrating suppliers using Kanban, initially for certain products at the Schiltach plant.

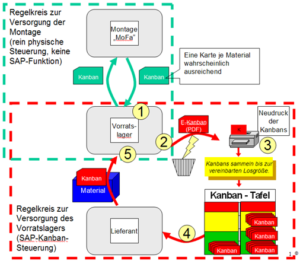

Hansgrohe chose one of the most important components of a modern mixer as the pilot area: the cartridge, the heart of every single-lever mixer. “Here, however, we have a very constant consumption of individual components, so it makes sense to integrate the suppliers via Kanban,” explains Jaeckle. Hansgrohe opted for a solution with a double control loop for supply: On the one hand, the assembly area from the supply warehouse and, on the other hand, for replenishment of the supply warehouse directly by the supplier.

The first control loop between production and the supply warehouse consists of a simple shuttle card solution. Once the material has been used up in production, the worker sends the card to the warehouse via a postal route agreed with all those involved. In the warehouse, this card is attached to the next pallet or packaging unit and transported to the designated storage location in production.

The second control loop for connecting suppliers extends beyond company boundaries and was therefore more complex. Here, Hansgrohe relied on SAP functionality: each Kanban card in the second control loop is managed in the SAP Kanban board with its current status. The status is set to “empty” or “full” by scanning the barcode on the Kanban card in the outgoing and incoming goods department. By setting the status to “empty”, SAP automatically creates an entry in the scheduling agreement. The Kanban card, which signals the need for subsequent deliveries, is automatically sent to the supplier as a PDF document by e-mail via message determination in SAP. All the customer has to do is print out the card, attach it to the goods and send it to Hansgrohe.

Another effect was the reduction in stocks: Stocks of materials that have been converted to the new process have already fallen by around 40 percent – and this with the best availability.

Expansion planned

The results achieved so far have convinced Hansgrohe. In addition to cartridge production, around 95 percent of space-intensive products have now also been converted to Kanban, and other areas are currently being implemented. And the international rollout of the “Logistics 2010” project is scheduled for 2007. Jaeckle: “We started in Germany to do our homework here first. Now that we see that it works, we’re taking it on.”