Management and IT – Procurement software

Bernd Reineke

Optimizing procurement processes by reducing inventories and increasing delivery readiness generally leads to smaller batches and shorter replenishment cycles. Software tools automate these processes and thus help dispatchers to work more efficiently than before, despite the increasing number of processes.

Providers of immediate stock programs are particularly familiar with the problem: in order to be able to deliver at all times, the warehouse is filled to the brim, and yet the items that the customer needs so urgently are missing. The company’s profitability suffers as a result: low cash flow due to tied-up capital, resulting in low financial flexibility, high capital costs and increased logistics costs. There are often additional complicating factors that result not least from industry-specific circumstances: high variant diversity, seasonal sales behavior or fluctuations in process manufacturers.

In numerous projects, Abels & Kemmner has worked out concepts and developed methods and procedures to achieve better operating results despite difficult boundary conditions. In the area of supply chain management, there is often potential to reduce inventories and make savings, resulting in a significant increase in liquidity and cost reductions, so that these projects pay for themselves within a short period of time.

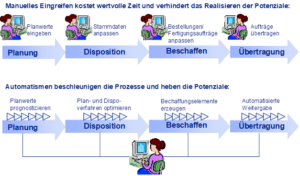

But the best results count for nothing if the concepts cannot be implemented. And the work starts with the implementation: The new processes need to be trained, understood and internalized. Areas of responsibility can change or be redistributed. The volume of work can also change drastically. If, for example, inventories need to be reduced, this often goes hand in hand with shorter order and production cycles as well as smaller batch sizes or order quantities. It is obvious that the number of production and order items is increasing, and with it the effort required to create and process these items. To ensure that the savings potential calculated when reducing the portfolio is not eaten up by the increased administrative costs, measures to reduce costs must be developed. Automation is the key word. What is already common practice in production and logistics is now increasingly finding its way into upstream administrative tasks.

The possibilities for automation here depend primarily on the IT systems used. Because these are usually standard systems, you very quickly reach the limits of what is feasible. Implementation without additional adaptations or additions is then hardly possible. The adaptation of IT systems is associated with correspondingly high costs and is often not even feasible.

In such cases, the use of established software tools such as DISKOVER is recommended for the automation of scheduling and procurement processes.

Optimal processes are characterized by the fact that the normal cases run through without interruption. This means that capacity does not need to be increased, even if the volume of operations increases, and the planner can concentrate on the exceptions.

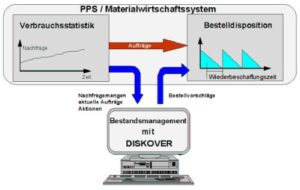

This is why many companies are pursuing a strategy of filling identified gaps in their IT environment with special solutions. In the area of inventory management, the DISKOVER optimization tool was able to compensate for deficits in many projects and even improve them. The software offers the prerequisites for optimizing processes from planning and scheduling to order proposals. In particular, the possibilities for automatic optimization of procurement parameters speak for the tool as a supplement to standard ERP systems. DISKOVER independently adjusts logistical parameters depending on the consumption behaviour of an article, determines the optimum forecasting procedures and optimizes the process parameters within a permissible framework.

Integrating the software into the company’s IT structures is relatively simple and requires little effort. While the existing IT systems and Diskover remain standard, existing transfer programs that can be adapted with little effort are used to link the systems. Depending on requirements, additional logic can be set or added in these interface programs to further optimize processes.

Integrating the software into the company’s IT structures is relatively simple and requires little effort. While the existing IT systems and Diskover remain standard, existing transfer programs that can be adapted with little effort are used to link the systems. Depending on requirements, additional logic can be set or added in these interface programs to further optimize processes.

For example, delivery dates of the order proposals can be adjusted to the delivery days of the suppliers. Order quantities can be optimized by taking price scales into account. Or requirements at assembly or product level can be broken down to components using the BOM explosion. The aim is always to reduce the workload of the planners and purchasers and to adopt the results without any further changes. This provides the basis for automating the processes.

Of course, monitoring automated processes is essential. Therefore, regulations and indicators must be developed to prevent processes from getting out of hand. If certain threshold values are exceeded or events are triggered, a message is sent directly to the screen of the person responsible.