SCM – The Würth Group, a trading company for fastening and assembly materials, is drastically reducing stocks at its Belgian site while maintaining the same high level of service.

What should a company do if it discovers that the stock level, i.e. the specific stock level, in individual companies is independent of sales per item? At Würth, for example, there are companies with a turnover of EUR 1,500 per item and companies with a turnover of EUR 30,000 per item per year. The respective stock turnover, i.e. the relative stock value, was generally identical. This was the task facing the Würth Group, a globally active trading group with 376 companies in 84 countries and an in-house production share of four percent. Originating from a two-man business, the Würth Group is now a provider of solutions for fastening problems of all kinds with its core business range of over 100,000 products, including screws, screw accessories, anchors, chemical-technical products, furniture and building hardware, tools, storage and retrieval systems.

What should a company do if it discovers that the stock level, i.e. the specific stock level, in individual companies is independent of sales per item? At Würth, for example, there are companies with a turnover of EUR 1,500 per item and companies with a turnover of EUR 30,000 per item per year. The respective stock turnover, i.e. the relative stock value, was generally identical. This was the task facing the Würth Group, a globally active trading group with 376 companies in 84 countries and an in-house production share of four percent. Originating from a two-man business, the Würth Group is now a provider of solutions for fastening problems of all kinds with its core business range of over 100,000 products, including screws, screw accessories, anchors, chemical-technical products, furniture and building hardware, tools, storage and retrieval systems.

The company, based in Künzelsau, Swabia, has been growing at double-digit rates on average every year for years and will achieve record sales again in 2007. This long-lasting success is the result of the consistent implementation of a holistic logistics solution right from the start. “We have not deliberately set milestones for the future, but have permanently adapted the development of logistics to our market requirements and strong expansion,” explains Armin Breitner, responsible for Group logistics.

The various companies are continuously working on individual projects to improve logistics processes, be it the use of efficient and simple warehouse technology in the central warehouse in Künzelsau or the expansion of the European distribution network towards Eastern Europe (see LH 11104). The acquisition of new companies and the development of innovative products for new markets have led to an enormous increase in the number of articles and national companies in recent years. The Group is therefore constantly working on optimizing its inventories. At the same time, the company strives to provide customers with an optimum level of service.

Potential through portfolio improvement

Würth began the project on logistics strategies for opening up the Eastern European market around three years ago. In the course of the project, the question arose at the beginning of 2005 as to whether a decentralized strategy with the management of a warehouse in each country or a centralized structure with a regional Eastern European central warehouse should be pursued. The main advantages of a central warehouse solution lay in inventory optimization.

In this context, the project team examined all inventory situations of all national companies in relation to sales per item. “Due to the enormous sales growth of the entire Würth Group in recent years, there was inevitably considerable potential in inventory optimization. This should have resulted in a higher inventory turnover and therefore a lower inventory value,” explains Breitner.

At the same time as considering how the potential could be leveraged by improving inventory, Breitner received a promotional letter from Abels & Kemmner Gesellschaft für Unternehmensberatung mbH, Herzogenrath/Aachen, on the subject of optimizing scheduling. The Herzogenrath team’s concept was so convincing that a national company had to be won over for the pilot. Breitner: “As a retail group, we are organized very decentrally and only provide solutions for the companies from the head office. Each managing director is responsible for their own company.” In the end, the Group logistics specialist was able to win over the Belgian colleagues for the existing project.

The aim was to reduce stocks sustainably. The current delivery service level of 98.5% should not deteriorate. With increasing throughput, a reduction in stock usually also inevitably leads to an increase in the number of order and goods receipt items. A further objective was to ensure that inventory optimization did not have a negative impact on the processes in materials planning and incoming goods. This is because our Belgian colleagues were already working quite effectively in these two areas with minimal staffing levels, so their productivity should remain unaffected. Similarly, the associated higher order and delivery frequency should not come at the expense of other areas and processes.

Analysis of articles and consumption patterns

The project started in March 2005 with the first potential analyses to determine whether it was worth getting involved in the project properly. The result was clear, so the next step for the Belgians was to analyze their product ranges in greater depth. Belgium has around 27,500 items in the system, of which around 10,500 items were excluded from the investigation as non-commercial goods. Of the remaining almost 17,000 items, 3,500 are not in stock and are procured on an order-related basis as required. This ultimately left around 13,500 item master data for simulation and inventory optimization.

Würth Belgium used the simulation tool from the consulting firm Abels & Kemmner to determine the appropriate scheduling parameters. This calculation tool determined the consumption patterns for the various articles and summarized them in corresponding article clusters. “We used the simulation process to calculate the optimum or minimum stock procedure for a given delivery readiness level,” explains Head of Logistics Michel Mondelaers. “We couldn’t lump all items together, but selected the appropriate combination of processes and parameters first for specific item classes and then for each individual item.”

For the Belgian subsidiary, this meant calculating suitable combinations for 13,500 MRP-relevant items. Each article resulted in between 80 and 100 different solution variants. For example, the average monthly requirement can be calculated using various statistical methods, such as arithmetic mean, weighted mean, median method, exponential smoothing 1st order or 2nd order. But which is the right procedure? This question also arose, for example, for the safety stock, which can also be calculated using different methods and with different parameter settings.

“Nowadays, we can no longer expect a scheduler to calculate these parameters for all items. This is generally a basic problem: we introduce SAP systems today and set the relevant parameters to the best of our knowledge and belief – but ultimately in a relatively generalized way across all items, perhaps still somewhat according to ABC structure, but by no means optimally,” Breitner explains the situation as it is found in many companies. The real potential only becomes visible through the individual optimization of each article. While the Würth crew was still skeptical at the start of the project, the simulation results were so convincing (see also “Inventory resource”, p. 30).

Just six months later, in September 2005, the national company converted the first 100 test articles to the newly determined disposition methods. The simulation tool from Abels & Kemmner continued to be used in the background as a calculation model. This is because the IT system that exists in the Belgian central warehouse was not able to do enough in terms of scheduling. The team led by project manager Mondelaers connected the simulation tool to the actual IT system as a scheduling tool via interfaces. The new tool calculates the order proposal for each item and transmits it to the existing ERP transaction system, which then continues to trigger the order.

New scheduling tool used

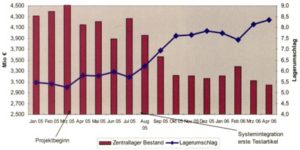

Our Belgian colleagues very quickly exhausted the huge savings potential at the beginning. Later, the pace slowed down. The team was even forced to take countermeasures due to the deterioration in the level of service (see chart on portfolio development). During the re-analysis, the company realized that some promotions were not planned correctly, sellers were circumventing the bulk quantity regulation or certain master data was incorrect.

In the meantime, Belgium has converted all articles and set up the corresponding scheduling parameters Further improvements are being planned. “We are currently working on keeping processes stable in every department and monitoring our suppliers better. We also want to be able to intervene more quickly if there are delays in delivery that have a direct impact on the level of service,” explains Breitner.

The project in Belgium was officially completed in mid-2006. With visible success, as the team states with satisfaction: “We have reduced the portfolio by 28% of the initial portfolio, i.e. from EUR 4.5 million to around EUR 3.2 million. Not only were we able to maintain a constant service level of 98.5 percent, but we were also able to further automate scheduling through better forecasting data,” Mondelaers summarizes the results.

Better planning

The forecast data is passed on to the internal manufacturers to enable better planning of production and reserve stock. In addition to optimizing and adapting the order quantities to the storage units, the Belgians have also increased the proportion of storage units that can be stored directly. Faster and more efficient goods receipt due to loading equipment-related order and delivery quantities means that goods are now available much more quickly.

The potential savings of EUR 1.3 million for the reduction in inventories alone and the associated higher liquidity of the national company are offset by relatively low external costs. The license fees for the new scheduling system and the consulting fees amounted to EUR 100,000. An investment that has more than paid off for Würth Belgium.

The Würth Group

The Würth Group, based in Künzelsau, Baden-Württemberg, is active with 375 companies in 84 countries around the world and has developed from a simple screw wholesaler into one of the leading suppliers on the fastening and assembly technology market.

In 2006, the company employed over 54,900 people worldwide and closed the 2006 financial year with consolidated annual sales of EUR 7.75 billion, an increase of 12.1 percent on the previous year. The pre-tax operating result of EUR 515 million exceeded the previous year’s record (2005: EUR 455 million) by 13.2 percent.

The successful business development continued in 2007 with new sales records in the first quarter. For the end of 2007, the Würth Group is aiming for sales growth of around 10 percent to approximately EUR 8.5 billion.

Supply Chain Manager 2007

On the occasion of the Management Circle event “Supply Chain Manager Forum 2007”, the award ceremony “The Supply Chain Manager 2007” took place in Frankfurt/Main at the end of April. In cooperation with the University of Cologne and other jury members (see picture), the organizer selected the best SCM project from among the applications according to the motto “Streamline structures, create transparency, live flexibility!”. Würth GmbH & Co KG and its successes in structurally optimizing inventory and scheduling at the Belgian subsidiary were chosen.