Supply chain check at pharmaceutical manufacturer Heel

Dr. Werner Hofmann 1, Dr. Götz-Andreas Kemmner

As part of an analysis, Biologische Heilmittel Heel GmbH evaluated the supply chain management of all international production sites by teams from the company headquarters. Abels & Kemmner carried out an external review at the company headquarters in Baden-Baden, Heel’s largest production site. The aim was to determine the efficiency of the supply chain and possible potential for improvement.

Biologische Heilmittel Heel GmbH is one of the world’s leading manufacturers of homeopathic medicines. Specialties are modern homeopathic complex remedies based on homotoxicology, a special method within homeopathy. The scientifically very active company belongs to DELTON AG in Bad Homburg. With around 1,200 employees, Heel generates 70 percent of its turnover abroad. The company exports to more than 50 countries from its headquarters in Baden-Baden. Heel is represented in ten countries, including Germany, by its own subsidiaries, some of which also produce products themselves.

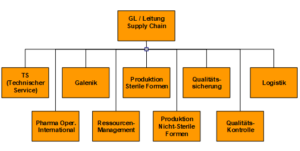

In its management mission statement, Heel defines committed employees as the most important factor for its success. However, the consistency and efficiency of the value chain are also of the utmost importance to the company. For this reason, Heel combines the planning and control of the value chain and its physical processing under the responsibility of Supply Chain Management (SCM). The SCM area of responsibility therefore includes resource management (procurement) and galenics (production of dosage forms), production of sterile and non-sterile forms, quality assurance, logistics and technical service, thus covering the entire operations management.

Supply chain efficiency plays a major role throughout the pharmaceutical industry. In order to further strengthen its international competitive position, the Heel Group evaluated all international production sites in the course of 2007. An internal project team from the Baden-Baden headquarters carried out the analysis at the foreign production sites. At the Baden-Baden site, Heel’s supply chain specialists did not want to evaluate themselves, but also undergo an objective, professional review. Abels & Kemmner was commissioned with this task in the fall of 2007.

“The supply chain review, whose final decision-making tool was a constraint analysis, uncovered some issues that are not immediately apparent when dealing with day-to-day business. It has provided a valuable basis for decision-making, particularly for our current and future optimization projects,” sums up Dr. Werner Hofmann, Head of Supply Chain at Heel.

Focus on organizational processes and IT

The task for Abels & Kemmner was to check,

- whether the entire “Operations” process is set up correctly,

- where the strengths and weaknesses of today’s supply chain lie and

- in which areas of activity performance reserves/potential can still be uncovered.

This had to be considered:

- the organizational processes,

- the associated support for processes in the SAP system,

- the interfaces between the individual departments,

- the distribution of competencies and

- the interfaces to exposed departments outside the supply chain. The areas of forecasting and regulatory affairs were particularly important here.

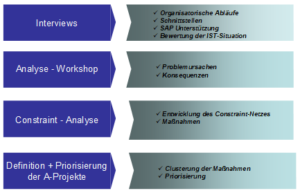

The aim was to identify potential bottlenecks, define necessary areas for action and identify possible “quick fixes”. The project began with interviews with all those responsible along the value chain. This involved clarifying the organizational processes as well as exchanging information with other departments within and outside the Supply Chain division. Heel uses SAP to control materials management and production. The extent to which the SAP system effectively supports the business processes and organizational procedures therefore also had to be examined. Coupled with the consultants’ experience, these interviews enabled an initial rough assessment of the current situation.

In order to carry out the review as effectively and quickly as possible, the consultants from Abels & Kemmner used the constraint analysis method for further problem analysis.

Constraint analysis is an element of the Theory of Constraints developed by the American-Israeli physicist Eliyahu Goldratt. TOC assumes that every organizational-technical system continues to grow until a system element reaches a limit (= bottleneck). If this bottleneck is recognized and eliminated, the system continues to grow until another system element reaches a bottleneck. The bottlenecks can be of a technical or organizational nature, but they can often also consist of internal regulations, principles or company policy. Constraint analysis is a systematic method for identifying the bottlenecks that are addressed.

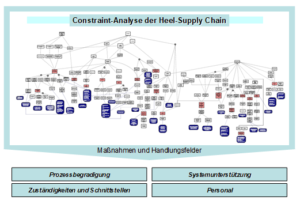

The constraint analysis corresponds to a vulnerability analysis. The decisive addition is that supposed or obvious weaknesses (effects) are examined with regard to their underlying, not always directly recognizable core causes. These root causes must be eliminated in order to eliminate the observed weaknesses, as if in a row of falling dominoes. Once the core causes are known, the fields of action to be taken can be clearly derived. The result of the constraint analysis is a so-called reality tree, which, like a circuit diagram, shows the cause-and-effect network between recognized symptoms and the core causes mentioned.

The interviews conducted were only a first step in identifying possible supply chain constraints at Heel. As part of an analysis workshop, aspects of the current supply chain that were rated as negative were compiled together with the division’s managers. The causes of these negative aspects and the resulting consequences were then worked out together.

The results of the analysis workshop in conjunction with the findings from the interviews provided the basis on which the consultants were able to construct an initial draft of the constraint network. Based on the core causes identified, the consultants developed proposals for their elimination, summarized them into packages of measures and divided them into the four fields of action:

- Process straightening

- System support

- Responsibilities and interfaces and

- Personnel.

categorized.

The developed constraint network as well as the proposed measures and defined fields of action were verified, adapted and approved in a project planning workshop.

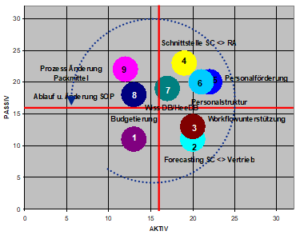

As the packages of measures developed in the individual fields of action all originated from the constraint network, there were understandably interactions between them. In a final step, it was therefore necessary to evaluate these interactions in order to tackle those packages of measures first that

- on the one hand, are least influenced by the other packages of measures and

- on the other hand, itself exert the greatest influence on other packages of measures.

The interactions were evaluated in a so-called influence matrix and presented in an influence portfolio.

In summary, it was shown that Heel’s supply chain management is very well positioned. Potential for improvement was identified above all at the interfaces to other areas and in system support.

Working groups made up of employees and managers from Supply Chain Management are now systematically working on these optimization measures together with the other divisions, because if you stop improving, you stop being good.

Reviews with subsequent “supervision” are particularly effective

Even companies that pay very close attention to their supply chain and employ several supply chain management specialists need regular external reflection for optimal supply chain alignment, because technologies as well as structural and personnel conditions change and the constant internal view can also lead to “blinkered thinking”. Constraint analysis has proven to be the ideal tool for such supply chain reviews, as the packages of measures resulting from these analyses do not address the symptoms, but the roots of the problem. At the same time, once the constraint networks have been created, they provide a good basis for continuous reflection and subsequent supervision.

Supervision has proven to be an effective approach for safeguarding the implementation of the results of a supply chain review. However, Abels & Kemmner does not understand supervision to mean the control of those involved, but rather the support of the experts by agreeing objectives for a specific period and regularly monitoring success. The aim is to keep an ongoing improvement process alive. However, setting objectives, reviewing the implemented measures and results, reflecting on experiences and continuously adjusting objectives can lead to the coaching process.

1 Dr. Werner Hofmann is Director Supply Chain at Biologische Heilmittel Heel GmbH in Baden-Baden.