Supplier integration

Following the successful conversion of the procurement chain to pull processes, bathroom and sanitary specialist Hansgrohe is taking a further step towards optimizing the supply chain: the innovative company is now tackling supplier integration using Kanban.

The changeover initially took place in a clearly defined, manageable pilot area. Organizational tools are used as well as the possibilities in SAP. Hansgrohe AG’s approach was anything but typical: in order to achieve rapid success, the international mixer and shower manufacturer switched from push to pull processes for production and raw materials in parallel. To convert production, the “global player from the Black Forest” engaged the lean production specialist Leonardo Group (a cooperation partner of Abels & Kemmner), Munich, who prepared and implemented the processes in detail on the lines. Abels & Kemmner, Herzogenrath near Aachen, had the task of optimizing the purchasing materials. In order to achieve results quickly here as well, a two-stage approach was taken.

First, the disposition of raw materials was switched to the drawing reorder point procedure. The results achieved, around 30 percent stock reduction and more, have already been presented in the . In the second step, the raw materials were converted to supplier Kanban.

Close coordination

The integration of the suppliers began right at the start of the project: The logistical key figures and parameters that are decisive for the dimensioning of the Kanban control loops were defined in close coordination. The existing supply agreements were also reviewed and adjusted with regard to delivery flexibility and collateral. The aim was to avoid breaking the supply chain for assembly at all costs.

One of the most important components of a modern tap served as the pilot area: the cartridge (also known as the “motor”), the heart of every single-lever mixer tap. If the supply chain breaks down here, large parts of the business would come to a standstill. But it was precisely because Abels & Kemmner had confidence in the new methods to be used and the necessary experience that this project was approached consistently. The following special framework conditions had to be taken into account in the Kanban pilot area:

- Lack of space in the assembly area, where the Kanban parts are installed but only a small proportion can be stored

- Quotation of materials (expansion elements, ceramic disks) to two to three suppliers

- Mapping of the supplier Kanban control cycle in the SAP system with simultaneous long-term forecasting of requirements.

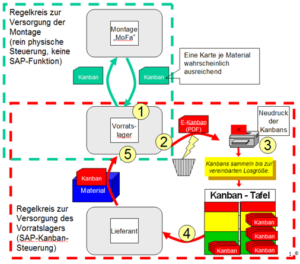

A special feature of the solution is the double control circuit for the supply

- of the assembly area from the supply warehouse and

- for restocking the warehouse directly by the supplier.

The first control loop between production and the supply warehouse consists of a simple shuttle card solution. Once the material has been used up in production, the worker sends the card to the warehouse via a postal route agreed with all those involved. In the warehouse, this card is attached to the next pallet or packaging unit and transported to the designated storage location in production. This control cycle does not require (re)posting in the SAP system. The material withdrawal postings are backflushed with additions to the higher-level production order.

The second control loop for connecting the suppliers was more complex to design and implement. Here, the flow of goods had to be accurately booked across company boundaries. This was realized by using the full SAP functionality (see figure above). Each Kanban card in the second control cycle is managed in the SAP Kanban board with its current status. The status is set to “empty” or “full” by scanning the barcode on the Kanban card in the outgoing and incoming goods department. Setting the status to “empty” automatically creates an entry in the scheduling agreement in SAP.

The Kanban card, which signals the need for subsequent deliveries, is automatically sent to the supplier as a PDF document by e-mail via message determination in SAP. All the customer has to do is print out the card, attach it to the goods and send it to Hansgrohe. At this point, the supplier had to take precautions to avoid double printing of the Kanban cards and thus an overdelivery of the material.

ln Hansgrohe AG’s incoming goods department, the goods receipt posting for the corresponding delivery schedule is made directly by scanning the Kanban card barcode. The usual quality inspection in the incoming goods department is now no longer required. Instead, the company relies on the supplier’s quality inspection, provided that this has been sufficiently proven in the previous customer-supplier relationship. By using the credit memo procedure in SAP, the effort involved in the entire order processing is reduced to a minimum.

Another effect is the reduction in inventory: Stocks of materials that have been converted to the new process have already fallen by around 40 percent, while maintaining optimum availability. The simulation carried out by Abels & Kemmner shows an overall reduction potential of well over 50 percent.

With these pleasing results, Hansgrohe is looking forward to the coming years with positive expectations. “On the production and logistics side, the company created the basis in the past financial year to be able to cope well with further growth,” says Siegfried Gänßlen, Chairman of the Management Board. p/ds

Hansgrohe

In its 107-year history, Hansgrohe AG, headquartered in Schiltach in the Black Forest, has earned a reputation as an innovation leader in technology and design within the sanitary industry.

In 2007, the company generated sales of EUR 661 million (2006: EUR 569 million) with its Axor, Hansgrohe, Pharo and Pontos brands – an increase of 16 percent compared to the previous year. This is the fourth year in a row that the company has recorded double-digit sales growth. The foreign share has now reached 79 percent. Today, the Hansgrohe Group employs more than 3,200 people worldwide.

The company currently produces in five German plants, in France, in the Netherlands, in the USA and in China. Another plant is currently under construction in Offenburg.

Leonardo Group

The Leonardo Group was founded in 1998 and has its international headquarters in Zug, Switzerland. Project offices are located in Germany and France. In the USA, the Leonardo Group is represented by partners. The company is a catalyst between science, technology and “reality” in manufacturing and supply chain management. Thanks to intensive contacts with leading institutions in Europe and the USA, the Leonardo Group is able to translate new developments into practical solutions for the industry. This becomes clear through innovative approaches to training and software.

Abels & Kemmner cooperates with the Leonardo Group on overlapping topics in the area of supply chain management, with Leonardo focusing on production-related topics. With extensive know-how and sophisticated tools, Leonardo implements the Kanban/Pull philosophy by consistently adapting production processes and production lines, taking into account the respective product mix.

LOGISTICS TODAY SLOW MOTION

Our interested readers have probably often asked themselves: What has actually happened to an interesting topic? How have individual projects developed? Have the successes that a company had hoped for actually materialized? Were the targets set possibly even exceeded? Or did the company have to change its strategy in order to remain competitive?

LOGISTIK HEUTE takes up important topics from past years again here and reports on developments and experiences, successes and disappointments of interesting projects in logistics in its “slow motion”.