CHIRON increases flexibility and reduces stock levels

From Andreas Gillessen

A Kanban system was introduced under SAP for the introduction of JIT assembly of tool arms for workpiece changing in CNC production centers at CHIRON-WERKE GmbH & Co. KG in Tuttlingen, as well as for the procurement and production of the required assemblies and components. During the implementation with SAP, which was to take place without customization programming, a number of things had to be taken into account in order to optimally adjust shortened throughput times, reduced stock levels, high flexibility and delivery readiness.

CHIRON produces vertical CNC machining centers. The machining centers are manufactured in series production, but can be adapted to individual tasks using a modular system. The product range includes 5-axis universal milling machines, long-bed machining centers and one- or two-spindle machining centers with integrated workpiece changers. Tool arms are required for the workpiece changers, the assembly of which was to be converted to JIT at CHIRON. The aim of this changeover is to improve delivery readiness while at the same time reducing stock levels. The question of feasibility was clarified by a preliminary data analysis. This delivered an inventory reduction potential of 43 percent of the existing inventory value at the start of the project. In order to convert tool arm production to JIT, stocks were moved to the variant-forming component level before tool arm assembly. Kanban control is now used to ensure the availability of components, assemblies and, ultimately, tool arms.

CHIRON produces vertical CNC machining centers. The machining centers are manufactured in series production, but can be adapted to individual tasks using a modular system. The product range includes 5-axis universal milling machines, long-bed machining centers and one- or two-spindle machining centers with integrated workpiece changers. Tool arms are required for the workpiece changers, the assembly of which was to be converted to JIT at CHIRON. The aim of this changeover is to improve delivery readiness while at the same time reducing stock levels. The question of feasibility was clarified by a preliminary data analysis. This delivered an inventory reduction potential of 43 percent of the existing inventory value at the start of the project. In order to convert tool arm production to JIT, stocks were moved to the variant-forming component level before tool arm assembly. Kanban control is now used to ensure the availability of components, assemblies and, ultimately, tool arms.

Conceptual approach

Bernd Rudolf, Head of Production, and Dipl.-Ing. Volker Göddertz, Head of Logistics at CHIRON-Werke, wanted a card Kanban system with a link to the SAP Kanban system. This was to be ensured without any adaptation programming.

Many details had to be considered in order to ensure a successful Kanban introduction, as the concept was not “standardized” according to SAP, but developed in a function-optimized way. The following Kanban processes should be used:

- Event-controlled Kanban for tool arm call-offs (JIT assembly)

- Card Kanban system for urgent spare parts requirements for the tool arms

- Container Kanban system for the pre-assembly of components

- Collective Kanban system for in-house production of components

- Card Kanban and container Kanban system for supplier integration.

- 2-bin Kanban system and transfer Kanban for small parts and bulk goods

Objectives of a Kanban system

- Reduction in throughput times

- Inventory reduction

- Improving the ability to deliver

- Simplification of the organization

- Increasing flexibility

Typical objectives of a Kanban system

In particular, the requirement to implement a collective Kanban with traffic light control in SAP was problematic, as the SAP standard does not offer collective Kanban as an independent function. Instead, a production order is triggered in the SAP standard for each Kanban container, to which the stored setup times are also posted. Collecting the Kanban containers until the required batch size is reached and only generating a Kanban production order with a setup time using this batch size was only possible without adjustment programming by combining two SAP control cycles consisting of batch production Kanban and stock transfer Kanban.

The benefit of the collecting kanban with traffic light control is that it makes in-house production more flexible. This is because production only has to start when the number of Kanban containers is in the “red” range. Once the number of empty Kanban containers is in the “yellow” area, production can begin. This flexibility allows the production area to determine the time and quantity of subsequent deliveries itself. All production-relevant parameters such as container quantity, number of parts per container, minimum and maximum production batch sizes, lead, set-up, production and transport times as well as reject quantities, customer production batch sizes, etc. were taken into account for the design. In this respect, the Kanban portfolio, which was considered optimal, could also be integrated into SAP without the need for customization programming.

Sticking points in Kanban with SAP

1. a collective Kanban can only be integrated into SAP without customization programming if two SAP control cycles are set up: Lot production Kanban and stock transfer Kanban.

2. control loop dimensioning at SAP is based on the classic Kanban formula and therefore falls short. Optimum values can only be achieved if seven other control variables are included.

Control loop dimensioning

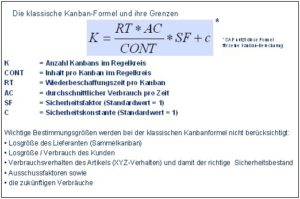

However, another requirement for an optimized Kanban system cannot be adequately implemented with SAP: control loop dimensioning. It must be carried out regularly, as there are always fluctuations in customer demand, changes in production processes and production parameters. As a rule, however, control cycle dimensioning is only carried out using the “classic” Kanban formula, which is also used in the SAP PP module. The parameters

- Replenishment time per Kanban,

- Average historical consumption of the item,

- quantity per Kanban container and the so-called

- Safety factor that is specified manually by the user,

however, are not sufficient. With this formula, the dimensioning of the circulating kanbans and thus the stand height essentially depend on the safety factor, which is not determined mathematically and analytically, but by “gut feeling”. Furthermore, the classic Kanban formula does not take into account all the variables that need to be considered.

Kanban formula

This is why the classic SAP Kanban formula falls short. Optimal Kanban control loops can only be achieved if other control variables are included:

- Lot size of the supplier (collective kanban)

- Batch size / consumption units of the customer

- Consumption behavior of the article (XYZ behavior)

- Scrap factors

- Delivery reliability

- Capacity situation / flexibility / lead time and

- the expected future consumption

For this reason, CHIRON uses Kanban dimensioning from Abels & Kemmner.

The Kanban dimensioning system from Abels & Kemmner takes the requirements of the tool arms from the SAP consumption or SAP SOP data and uses the BOM explosion to determine the requirements for all Kanban-controlled components. These values form the basis for dimensioning because they are used to determine the basic and safety stock for each component depending on the consumption behavior (XYZ components). The defined parameters of each individual component and a simulation period of 5 years are now used to test the number of kanbans that need to be fed into the system. The safety stock is constantly monitored to ensure that it is sufficient to prevent the system from running empty and that no superfluous Kanban containers are circulating in the system. Employees are provided with the following results, among others, to evaluate the system:

- Number of kanbans required and difference to the current situation

- Maximum number of Kanban containers in the storage area

- Minimum, average and maximum stock levels

- Basic and safety stock on the basis of the WBZ

- Calculation of the average monthly setup processes

The dimensioning can now be repeated several times by changing the parameters. This allows improvements in stocks, set-up processes, etc. to be weighed up against changes to the parameters.

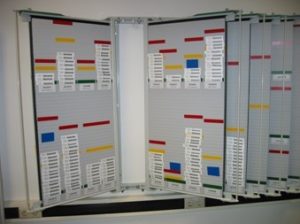

The Kanban system in practice at Chiron

The changeover to JIT production with Kanban control first required an organizational change in the affected areas: The tool arm assembly was given a new assembly layout. The type and design of the assembly workstations (tools, gripping areas and walkways) and the associated storage areas (“supermarket”) were also renewed. The aim of the workplace design was also to use suitable tools to increase productivity by increasing the throughput per arm and worker. These activities were managed and implemented by CHIRON. However, Abels & Kemmner accompanied these activities as a sparring partner and by providing the necessary input. Today, tool arm assembly is JIT. What this means varies depending on whether it is a new or replacement order:

JIT new orders – Two days air

Thanks to short set-up times and short throughput times, the tool arms can be assembled with batch size “1” and made available for final assembly at the production centers at short notice. The call-offs are triggered via the so-called event-driven SAP Kanban. The logistics center triggers its requirements in SAP and generates a production order in SAP, which is then immediately printed out in the tool arm assembly department. The tool arm assembly must meet the requirements with a maximum lead time of 2 days. The tool arms must then be ready for dispatch to the logistics center.

JIT spare parts – One day is already too long

However, some customers’ spare parts requirements must be able to be met immediately and directly. A lead time of less than 1 day may already be too long. A separate Kanban control cycle for spare parts requirements was created in SAP in order to be able to meet these requirements. This control circuit works with a safety stock of 5 tool arms. If requirements are covered by this safety stock, the tool arm assembly department must replenish it at short notice. Control here is carried out classically via Kanban cards, which are attached to the tool arms. The Kanban cards are made available to the assembly department during removal. Production orders are generated and completed in SAP via “empty” and “full” scanning of the Kanban cards.

Kanban warehouse before production

To ensure that sufficient components and assemblies are always available, the component store was designed as a Kanban store upstream of the tool arm assembly line to supply the tool arm assembly line. This approach made it possible to shift the increased warehousing away from the tool arm and back to a lower value-added stage (components instead of tool arms).

The security of supply of components means that changes in demand or additional requirements can be responded to and met at short notice. In addition, by shifting warehousing to a lower stage of the value chain, but above all before the actual variant-creating production stage, a higher delivery service was made possible while at the same time greatly reducing stock levels.

The goods are stored in a wide variety of containers. Some items are stored in a roller flow rack. This is also used to store components for the assembly of the so-called grippers.

Supplier Kanban

The only difference between the introduction of Kanban with external suppliers at CHIRON from the customer’s point of view is that “external parties” are also involved in the control loop. The selection of kanban-suitable articles is therefore understandably always linked to the selection of suitable suppliers. At CHIRON, three suppliers were integrated into the Kanban control system. At the same time, a changeover was made for these suppliers from classic order processing to delivery schedule lines. The “empty” and “full” scans of the Kanban cards or Kanban containers are used to generate delivery schedule lines and goods receipts for the delivery schedule.

For the remaining suppliers, most of whom only supply a small number of low-value components, the reorder point procedure was used for pull control. The necessary signaling and safety stocks were dimensioned accordingly.

Kanban: From the push to the pull principle

With Kanban, replenishment or additional deliveries may only be made if a certain quantity of a certain item has been consumed at a certain point. Cards (Kanban) or the production/transport containers themselves serve as information carriers for communication between the producing and receiving areas. Material is thus only drawn according to actual consumption. Kanban is simple, it demands and promotes the autonomous control of production units and creates transparency regarding consumption and stocks.

If the downstream value-added stage (customer) requests parts from the upstream value-added stage (supplier) via Kanban, the latter is responsible for the correct subsequent delivery, particularly with regard to the time, quantity and quality of the parts to the consumer (customer).

Implementation and introduction

The introduction of Kanban began with a change in the working methods and behavior of the employees involved at CHIRON. This alone necessitated the decentralization of production control back to the production areas. A key success factor in the introduction of Kanban at CHIRON was therefore the integration of employees into the system concept. All organizational processes were also developed together with the employees. In addition, a one-day management game was used in which the participants gradually optimize a production process and switch from push to pull control. The employees were thus trained and qualified in Kanban in a very short time to such an extent that requirements, tasks and problems arising from a changeover to Kanban could be assessed well. In this way, the employees’ trust in the concept and their understanding and identification with the overall processes and the detailed processes of the respective production areas could be created. And this is important, because employees are responsible for ensuring that components are delivered on time and in the right quality as part of the Kanban system. This increase in employees’ self-control skills is also the real reason for the considerable reduction in the control, coordination and booking work involved in Kanban control.

Thanks to the precise design of the Kanban system and the intensive and thorough preparatory work, it was possible to go live with the Kanban system without any major problems. All the preparations for the changeover were completed within just a few days. At the same time, the SAP processes were redesigned so that they do not hinder the processes of the Kanban system with additional administrative work.

In day-to-day operations, the solutions impress with their simplicity and transparency for all employees. However, it remains a permanent task for all employees involved in the system to further optimize the value chains in terms of throughput times, delivery service and inventories by further improving the framework parameters such as batch size, set-up and production times, reject rates, etc., because only a “living” Kanban with a control loop dimensioning that reacts to all relevant influencing variables can deliver optimal results in the long term.

The Kanban system did not trigger any reorders for almost six weeks – the excess stock was automatically reduced.