Electronic planning board optimizes control in complex gold spring manufacture

by Frank Derlien 1, Carsten Hense 2, Andreas Gillessen

Montblanc relies on electronic planning boards to quickly and efficiently cope with changing bottlenecks in the complex production of precious metal spring assemblies, which are manufactured in more than 35 production steps and in a very wide range of variants. The functional model, which was previously tested with a manual planning board system, significantly increased production efficiency. The electronic planning board system now helps to make the new production order control system very clear and efficient.

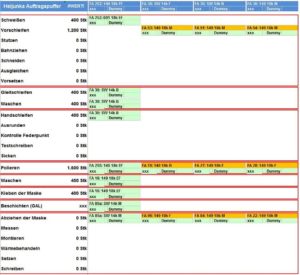

Always delivering on time is a real challenge for the production control of the nib unit production of the writing instrument manufacturer Montblanc from Hamburg. Due to the enormous increase in the product range in recent years, the complex, multi-stage production process must be monitored and controlled with a sharp pen. For this reason, an electronic production control and order tracking system was programmed for the spring units, which are manufactured exclusively by hand, and installed on 42-inch electronic planning boards in the spring production area. The enthusiasm of the employees was palpable from day one. The transparency gained, the associated possibility of optimizing employee deployment at the many different production stations with changing bottlenecks and the improvement in flow production with shorter idle times and lower WIP (work in progress) stock each played their part.

Always delivering on time is a real challenge for the production control of the nib unit production of the writing instrument manufacturer Montblanc from Hamburg. Due to the enormous increase in the product range in recent years, the complex, multi-stage production process must be monitored and controlled with a sharp pen. For this reason, an electronic production control and order tracking system was programmed for the spring units, which are manufactured exclusively by hand, and installed on 42-inch electronic planning boards in the spring production area. The enthusiasm of the employees was palpable from day one. The transparency gained, the associated possibility of optimizing employee deployment at the many different production stations with changing bottlenecks and the improvement in flow production with shorter idle times and lower WIP (work in progress) stock each played their part.

Constantly changing bottlenecks under control

A lot of data is hidden behind the electronic planning boards from Montblanc. Thanks to the aggregation of production orders on several levels, even complex production areas can always work in a bottleneck-oriented manner without major organizational effort.

The production process

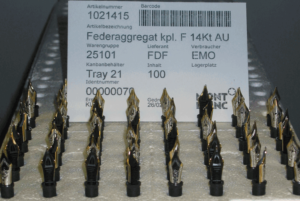

The 14 and 18 carat gold nibs wait in polystyrene trays to be used at the tip of the fountain pen during final assembly. Before they get there, however, they have undergone a complex, multi-stage, time-consuming and labor-intensive production process involving over 35 steps. If you consider this complexity, it quickly becomes clear that optimizing employee deployment in terms of lead time compliance, low WIP inventory and production efficiency is a major challenge for production management at Goldfedermanufaktur. The following aspects in particular must be taken into account:

- In flow production, not every spring unit passes through the same production stations.

- Each work step has very different processing times in some cases.

- Not all production stations are manned at all times.

- Despite a very high level of employee qualification, not everyone can carry out all work processes.

- Capacity limits must be observed.

Gold spring manufacture

These aspects, as well as the varying production order quantities and the fluctuating number of available employees in the production groups, lead to constantly changing bottlenecks in the production areas. However, each bottleneck sector limits the overall throughput and at the same time generates waste of resources for all other parts/orders. The entire operational planning must therefore be constantly realigned to the sometimes very short-term changes in bottlenecks. The alternating “weakest” sub-area always determines the operational planning in order to align the overall system for maximum efficiency.

In order to meet this challenge, the first requirement is to create complete transparency! The actual production situation must be visible at all times, not only for production control, but in particular also for the employees in the production areas organized in groups. In this case, transparency means answering the following questions:

- How high is the total production order backlog?

- How high is the order backlog at each individual production station?

- How many different production orders does it consist of?

- Which of these orders are due when?

- Which of these orders are already set to “yellow” or “red” at the traffic lights?

- Which of these orders have been given “additional” priority?

These questions are now answered by the electronic planning board in “real time”.

To create the necessary transparency, the first step was to test a manual planning board in one of the three production areas. Although this quickly produced the desired results, it was too complex to manage in terms of placement, operation and updating due to the large number of production orders and production stations. Based on the experience already gained, the electronic planning board could now be programmed and implemented very quickly in just a few days.

Behind the graphical user interface is a simple SQL database model in which the SAP production orders are updated daily. The user interface of the planning board is “Kanban”-simple, user-friendly and focuses on the essentials: creating transparency by visualizing the production orders waiting in front of the production stations, including information on traffic light status, volume and completion date.

The electronic planning board is positioned in the production area so that it can be viewed from almost all production stations – even from a distance.

Each employee operates the electronic planning board themselves. Once the employee has completed his operation, he goes to the electronic planning board and clocks his production order one operation further. This reduces the quantity of his operation and the subsequent operation is loaded.

The employee scheduling of the production groups is carried out daily, if necessary several times a day. The production orders and production order quantities that precede an operation are decisive for operational planning, in addition to the traffic light system and the additional priority indicators.

The transparency gained and the associated opportunity to deploy employees in a way that is always focused on bottlenecks in order to increase production efficiency could be used from day one. The time-consuming task of gaining an overview of all production stations in terms of quantities, deadlines and priorities has been completely eliminated thanks to the use of electronic planning boards. The improvement in flow production with shorter idle times and lower WIP inventory are further significant improvements that were achieved at the same time.

This example shows that even the most complex production processes can be controlled in a bottleneck-oriented manner using appropriate planning methods and tools without generating enormous planning effort and IT costs. Complete transparency at all levels, data in “real time” and a focus on the essentials when visualizing the data are important for bottleneck-oriented fine-tuning of production.

The spring unit manufacturing process in detail

The production of the spring units resembles a manufactory with flow production. The technique of getting the ink to flow evenly is essentially achieved through the interaction of an ink duct and the nib. At Montblanc, the gold nib comes from the 14- or 18-carat gold band. In the first steps, the gold strip is rolled, punched, stamped and molded. After these production steps, it is still possible to create variants in different nib widths (EF, F, M, B, BB, OM, OB, OBB, OBBB) and different surfaces (gold, fully rhodium-plated, partially rhodium-plated, etc.). This is why there is also a semi-finished product store after the compression molding process. However, the next work step, the welding of an iridium ball with a diameter of less than 1 millimeter, the so-called writing grain, heralds the start of the production process up to the finished spring unit. This production process consists of up to 35 different work steps, some of which require the highest manual precision. Every single Montblanc nib is sharpened by hand. After grinding, a fine capillary with a width of 0.12 mm is cut from the nib tip to the heart hole of the gold nib. The capillary forces transport the ink from the ink tank via the ink duct and from there via the finely cut capillary of the gold nib to the front of the nib tip.

This is followed by tumbling (automatic deburring by movement in a plastic granulate with additives and polishing for the required surface structure), rounding, polishing and repeated inspection operations to ensure compliance with the high quality requirements. After rhodium plating, electrolytic application of the rhodium and assembly, the gold nib is set. The gold nib is aligned by hand with such precision that, when tested with ink, it glides effortlessly over the paper and meets Montblanc’s high quality standards.

1 Frank Derlien is Head of Nib Production at Montblanc Simplo GmbH, Hamburg

2 Carsten Hense is Head of Production at Montblanc Simplo GmbH, Hamburg