Achieving sustainable optimization with rules and controlling

By Steffen Schwippl (Serag-Wiessner) and Dr. Bernd Reineke

It is certainly nothing new that industrial planning and procurement processes are a highly complex, interlinked set of different processes. But ever more intelligent and sophisticated solutions are making it increasingly possible to master the balancing act between conflicting objectives such as delivery readiness, inventories and costs. At Serag-Wiessner, the medium-sized manufacturer of medical and pharmaceutical products, it is also important to set the many parameters in such a way that the balancing act succeeds.

Product example Serag-Wiessner produces and supplies surgical suture material, textile implants for the pelvic floor and infusion solutions from its Naila site with around 200 employees. Of the approx. 3,000 items in the surgical sutures and textile implants division, which differ in terms of thread types, thread thicknesses, lengths and needle-thread combinations, approx. 1,500 items must be kept in stock from the dispatch warehouse. The approximately 25,000 customers, which include hospitals, doctors in private practice and wholesalers in Germany and abroad, expect a delivery time of 24 to 48 hours. To meet these requirements, stocks are held in the finished goods warehouse, which were previously dimensioned by planners and dispatchers on the basis of ERP order proposals. In the past, attempts to significantly reduce stocks by our own efforts did not lead to the desired success. The management therefore decided to entrust the supply chain specialists at Abels & Kemmner with this task. The most important requirement was to develop and implement a sustainable solution. In addition to a 100% suitable concept, the focus was therefore also on the implementation of the solution. The requirement to generate a consistent solution raised the question from the outset of how or whether the existing ERP system could support this solution. The restrictions in production and logistics had to be taken into account and included in the determination of the scheduling and planning parameters. In addition to the sales-oriented target figures – delivery times of 24 to 48 hours and an average target delivery readiness of 96% – the planning parameters therefore also had to ensure that the production orders and the associated set-up processes were limited to 1,200 per month.

The project objectives were determined in advance with the help of simulations. During implementation, it became apparent that success was only achieved after a tailored inventory controlling system with a few but meaningful key figures was introduced.

The project began with an inventory of the current processes and logistics parameters such as range, delivery readiness and stock turnover. An important aspect in this phase was also the analysis of the ERP system used at Serag-Wiessner. Although the SoftM system, which is based on an AS400 platform, has basic scheduling and forecasting functions, it became clear right at the start of the project that the project objectives could hardly be achieved without extending this system. The management therefore decided to purchase the missing functionality via the DISKOVER SCO optimization tool. This software from SCT GmbH is characterized in particular by strong functionalities in the following areas:

- Optimization through simulation

- Numerous forecasting and security methods (especially distribution-free methods)

- Optimization of scheduling parameters

- Integrated inventory controlling

As the decision to use DISKOVER SCO was made in the early project phase, the system’s capabilities could already be incorporated into the design, which meant that the project team had much greater scope for creativity.

The following sustainable goals were achieved as part of the scheduling parameter optimization project:

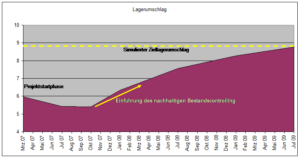

- Inventory turnover increased from 6 to almost 9, resulting in an average storage period of around 6 weeks.

- Stock levels have also been reduced to 65%. This is not at the expense of delivery readiness. On the contrary, delivery readiness was even improved to 96% and has been continuously maintained.

To find a solution, differentiated simulations were first used to determine the influences of delivery readiness, stocks and set-up costs. It quickly became clear that the project objectives could only be achieved with differentiated approaches. This means, for example, that different target delivery readiness levels were defined for different product groups, or that higher ranges were selected for the batch sizes for low-value C-items than for the high-turnover A-items. Ultimately, a set of rules in the form of a decision table was created as part of the concept, which took into account the criteria of the ABC and XYZ labels as well as the shelf life and market requirements of the various product groups. This set of rules has been mapped in DISKOVER SCO and can be flexibly adapted to changing requirements.

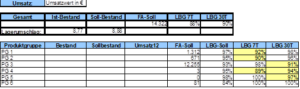

As part of the simulations, the achievable target values for delivery readiness, stock and set-up costs were determined in advance. However, the results did not materialize at the beginning of the implementation phase. The breakthrough for sustainable inventory reduction only came when daily inventory controlling was implemented. Inventories, sales, stock turnover and readiness for delivery are reported after each day and compared with the currently simulated target figures. In the case of delivery readiness, a distinction is even made between different time periods (7 days and 30 days) in order to be able to better assess the short-term development of delivery capability. This report is sent daily by e-mail to the screens of dispatchers and management. This allows those responsible to react quickly in the event of major deviations and take countermeasures if necessary.

The following figure shows an example report:

The development of the portfolio shows that DISKOVER inventory controlling has led to a sustained improvement in results.