Tools for optimizing and maintaining ERP scheduling parameters

By Dr. Götz-Andreas Kemmner

How do you ensure that your materials planning ensures that materials are ready for delivery as required while keeping stocks as low as possible and working even more efficiently?

This task can no longer be solved solely by the experience of the schedulers or by rough settings in the ERP system for article masters that are rarely less than a few thousand articles, but requires a differentiated and continuous optimization of the individual forecasting, planning and scheduling parameters, or “scheduling parameters” for short. Since, depending on the ERP system, around 30 to 130 of these parameters have to be set on an item-specific basis, their setting, which depends on the consideration of numerous company-specific influencing variables and interdependencies, can no longer be managed without expert knowledge and mathematically precise simulations. This is why the dispatcher needs suitable service providers and tools that ensure that the optimum item-specific dispatching parameters and logistical master data are determined, entered and effective. This is the only way to achieve optimum results.

The constant is the change

Unfortunately, however, it is not enough to determine and enter the parameters and master data once. If the properties of an article change, as is the case for at least 10% of articles every month, the MRP parameters and logistical master data for this article must be updated. Due to scarce time resources in the normal planning and scheduling business and the extremely high data maintenance effort, it is often not possible to check all items for changed properties and to update numerous parameters according to a decision table. This results in considerable annual costs, which are reflected in excessive inventories, poor delivery readiness, high depreciation and scrapping costs. For this reason, the parameters and data of software tools should be automatically updated in the ERP system on an item-specific basis, at least monthly, in order to always be able to react to the latest market developments.

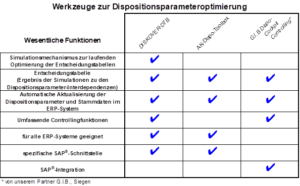

Abels & Kemmner supplies suitable software tools (DPO tools) with different levels of performance to suit requirements (see diagram). The core element of all these solutions is a complex decision table, which must first be developed for the specific company. The decision table specifies how the forecasting, planning and scheduling parameters available in the ERP system must be optimally set for each item. This depends on numerous influencing variables: These include, for example, the ABC class (importance) of an item, the XYZ class (regularity of demand), the STU class (number of demand originators), the ELA class (life cycle phase), procurement type, material type, delivery strategy and a whole range of other, company-specific influencing variables. It can already be seen here that the readjustment of individual parameters, such as the “safety stock”, can hardly be made as an individual decision. For this reason, suitable dynamic simulations of ERP system behavior are absolutely essential in order to create a sound basis for decision-making.

The results of these simulations are compiled in a comprehensive decision table, which must be used to regularly adjust the parameter settings in the ERP system on an item-specific basis. This task cannot be accomplished by hand. This is why all DPO tools from Abels & Kemmner offer automated update functions for the respective ERP system. But how do these different solutions differ?

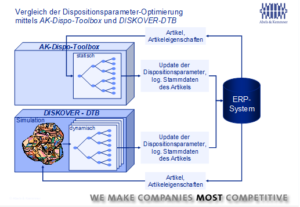

A key distinguishing criterion is the ongoing optimization of the decision tables (see Fig.). The A&K-Dispo-Toolbox is designed statically and ensures the optimization of scheduling parameters at the level defined at the end of each project, which is sufficient for smaller projects and as an entry-level solution. The decision tables themselves are updated manually and, if necessary, by the user. on the basis of new simulations, for example on an annual basis.

The DISKOVER-DTB software module goes further, as it not only adjusts the scheduling parameters, but also optimizes the decision tables independently and regularly through regular simulations. The use of this module is therefore particularly recommended for larger companies or companies with dynamically changing processes and fast innovation cycles. Both tools work as add-on systems to the ERP system and communicate easily with SAP systems via RFCs (Remote Function Calls).

With the SAP-certified G.I.B Dispo-Cockpit from our partner company G.I.B mbH, Abels & Kemmner also provides a solution that is fully integrated into SAP. In addition to the possibility of storing the decision tables developed in optimization projects here and thus automatically adjusting the scheduling parameters, the Dispo-Cockpit Controlling offers various controlling functions that are seamlessly integrated into SAP and ensure an enormous increase in transparency at the key figure level.

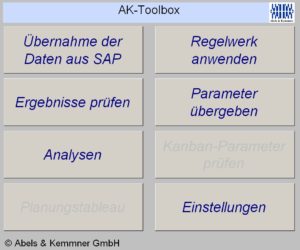

The A&K-Dispo-Toolbox: A simple tool with comprehensive added value

We make the A&K-Dispo-Toolbox available to customers as part of our project work. The system regularly recalculates the influencing variables and sets the scheduling parameters in the ERP system according to the decision table. This makes the A&K-Dispo-Toolbox an extremely flexible solution for maintaining scheduling parameters. It is used as part of supply chain optimization processes to sustainably reduce inventories while at the same time increasing delivery readiness. Excessive order quantities, orders or production orders that are triggered too early, unnecessary build-up of collateral in the form of inventories and delivery times are just as much a thing of the past as insufficient readiness to deliver.

The A&K scheduling toolbox makes it possible to optimize scheduling decisions by promoting communication.

DISKOVER-DTB: Powerful tool with integrated sustainability

Compared to the AK-Dispo-Toolbox, DISKOVER-DTB is an even more powerful solution that goes far beyond the capabilities of the AK-Dispo-Toolbox. It supports companies in regularly updating the decision tables once they have been drawn up in order to be able to adapt to changing market and competitive requirements. The software module regularly carries out simulations in the background. From the results of these simulations, it derives suggestions for optimizing the existing decision tables and automatically adjusts certain parameters and logistical master data in the decision table. Abels & Kemmner also offers automatic monitoring of the parameter settings. This expert monitoring ensures the automatic availability of expert advice, which is always required if the overall system should ever run the risk of getting out of control due to a wide variety of framework conditions. DISKOVER-DTB automatically transfers the relevant data to a monitoring tool from Abels & Kemmner. This issues an automatic warning message for certain parameter constellations. If this occurs, the Abels & Kemmner supervisor contacts the person responsible for the system and makes appropriate recommendations for action. Depending on the data available, these range from a simple tip to the dispatcher to recommendations for training or further optimization measures. This ensures the sustainability of the optimization measures, because every system is only as good as its user and even Formula 1 racing drivers are always in contact with the pit team online.

G.I.B – Dispo-Cockpit – full integration in SAP

G.I.B – Dispo-Cockpit – full integration in SAP

The MRP cockpit simplifies MRP work for users who work with SAP’s “collective access” for materials planning. All essential information is summarized and graphically visualized on one screen. Important for the optimization of MRP parameters: In addition to the procedures already available in SAP, the MRP cockpit offers the option of storing the desired MRP parameters for an item portfolio depending on ABC and XYZ criteria and automatically assigning these to the associated range of items. An integrated formula generator can also be used to enter any other decision parameters and tables. Decision tables developed for the optimum setting of scheduling parameters can thus be mapped and maintained. At this point it becomes clear that the decision tables play an essential role in all three solutions. The special feature of the Dispo-Cockpit is that it is fully integrated into SAP without interfering with the standard system.

Utilizing potential

Which solution you choose ultimately depends on the respective framework conditions. However, it is no longer advisable to operate without decision table functions, as the planning and scheduling processes of companies contain one of the greatest earnings levers that only a few companies have recognized and used efficiently to date: In planning and scheduling, decisions are made on a daily basis whose financial impact is often greater than the financial decision-making scope of many board members or managing directors. You should definitely make the most of this potential and reduce the risks as much as possible. All interdependencies must be taken into account. We will be happy to support you.