The Sauerland-based DIY store supplier GAH Alberts has halved its stock with external help, thereby exceeding its project target. Now the solution is reaching its performance limits.

For building, renovating and beautifying the home and garden, Herscheider Gust. Alberts GmbH & Co. KG (GAH Alberts) has over 10,000 items in its range, half of which are produced in-house. The majority of customers are DIY stores in Europe. The system provider also supplies wholesalers and specialist retailers, tradesmen and industrial customers throughout Europe.

In order to meet customers’ desired delivery quotas, the Herscheid warehouse focuses in particular on delivery readiness. For the storage of sheet metal, profiles, fittings, hooks, fences and many other products, 22,000 pallet spaces, around 2,700 storage tubs and 6,500 KLT spaces are available on an area of 24,500m2.

Many items, especially garden products, are subject to strong seasonal fluctuations in demand. From January to May, the 68 logistics employees at GAH Alberts put together up to 1,400 orders a day. The annual average is just 1,000 orders per day, and only 530 on slow days. On average, Logistics Manager Stefan Thomas counts around 70,000 picks per day (34,000 to 91,000) and around 12,500 items (7,200 to 17,000).

High safety stocks

Due to limited production capacities, GAH Alberts produces certain products weeks or months before the peak season. The most precise sales planning possible is crucial here, otherwise individual items will quickly lose the desired readiness for delivery. In extreme cases, other materials remain in the warehouse as slow-moving items.

In the past, the fear of planning errors and supply bottlenecks led to high safety stocks piling up at the Herscheid site. “Whenever the excess stock was too high, we launched optimization projects,” recalls Head of Logistics Thomas. However, many projects have failed because the planning and scheduling system in the SAP system introduced in 2003 could not be adapted sustainably.

This is why GAH Alberts brought Abels & Kemmner Gesellschaft für Unternehmensberatung mbH from Herzogenrath near Aachen on board in January 2009. The target was to reduce inventories by around 30 percent, half of which was to be achieved in 2009. After a rough assessment of the processes, the consultants carried out initial simulations, which identified the top 100 items with significant potential for inventory reduction. Until mid-2009, these were successively scrutinized in weekly “inventory driver workshops” to determine the causes of the inventory. An average of 20 employees from scheduling, sales or purchasing sat around the table.

The workshop participants discussed the procedure for each individual item directly on the ERP system. The meetings also served to break old habits and develop a common understanding of the processes. Another challenge was to map the master data cleanly. Specifically, batch sizes, production times and replenishment times were determined for the next three to six months. “We had to think in terms of production stages and also involve our suppliers. That was more complex than we thought,” reports Thomas.

The effort has paid off: after just four months, stocks had fallen by more than 13%, while delivery readiness remained constant at 97 to 98%. “However, we had inadvertently set a parameter incorrectly, which meant that we had short-term delivery problems with some items during the peak season. However, we quickly rectified this error,” admits the logistics manager.

Nevertheless, GAH Alberts achieved its target for 2009 in a third of the time. After nine months, the measures even resulted in a 35% reduction in stocks. The overall target was therefore exceeded. “Our one-off investment paid for itself after six months,” sums up Thomas.

While these short-term measures were still taking effect, the concept for the long-term optimization of planning and scheduling had already begun. With the help of a system-supported setting of certain MRP parameters, GAH Alberts switched its replenishment strategy from the previous push strategy to a pull strategy. Previously, employees had entered planned values into the SAP system twice a year, but in future a large proportion of the product range will be planned and scheduled based on consumption.

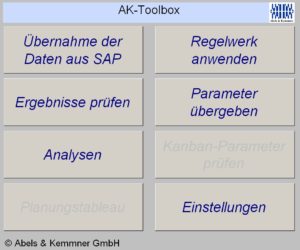

Toolbox decides

The “AKToolbox”, a tool from Abels & Kemmner, does this using various article parameters, including the consumption history of the last 60 months. Every month, the system automatically decides which items are suitable for consumption control. It also adjusts the safety stock and reorder level as well as the target delivery readiness level of an item every four weeks. After approval by the planner, the toolbox makes the necessary changes to the parameters in the SAP system via an interface.

Events, such as sales campaigns or new or lost customers, are promptly entered into the system by the sales staff. In “exception planning”, each sales employee makes absolute or percentage corrections to the statistical forecasts created by the system for each retail partner. These are then aggregated at item level. A nightly comparison between AK-Toolbox and SAP ensures that all special events are taken into account in sales planning.

This means that the responsibilities between scheduling and sales are clearly defined. By switching its strategy from push to pull mechanisms and introducing a rolling planning system that processes forecast and sales information into production plans, GAH Alberts is able to adjust its planning automatically on an ongoing basis.

“However, with 35 million data records in the toolbox, we have already reached the performance limit. From today’s perspective, the toolbox is not the most suitable instrument,” Thomas concludes. He is therefore currently considering the successor solution “DISKOVER” from SCT GmbH, although this would incur license fees. The manager therefore wants to test the functions of the new SAP release 6.0 first. A decision is expected to be made in summer 2010. p/akw

“Our one-off investment paid for itself after just six months,”

Stefan Thomas, Head of Logistics, Gust. Alberts GmbH & Co KG, Herscheid

GAH Alberts

Founded in 1852 as a bolt smithy, the DIY store supplier Gust. Alberts & Co KG (GAH Alberts) based in Herscheid, now has around 400 employees at five locations worldwide. In the 2009 financial year, the system provider for trade, commerce and industry generated sales of around EUR 100 million.