Minimum effort with maximum benefit

Abels & Kemmner is currently preparing a logistics benchmarking project to be launched in fall 2011. The highlight will be the largely automatic and therefore very fast and convenient recording of key figures as well as the company-specific determination of very precise optimization potential. As a result, companies benefit from minimum effort and maximum benefit.

We are regularly asked in discussions with companies: “What inventory ranges do other companies in our industry have? What about their readiness to deliver? Do others also need such high safety stocks?”

We have a whole range of empirical values from our projects. However, the time lag between different projects means that the figures were recorded in different economic situations.

Inspired by discussions in the AWF’s inventory reduction working group, we decided to set up an inventory and delivery readiness benchmarking project. Data collection will begin in the fall of 2011.

Clou 1: High data quality through automated data collection

An essential prerequisite for any benchmarking project is the precise definition of the key figures as well as careful compilation and preparation of the figures by the participating companies. However, it is precisely the latter that causes the data quality of many benchmarking projects to fail. Many companies understandably shy away from the effort of extracting the numerical values for differentiated key figures from the ERP system and preparing them precisely in accordance with the specifications.

We therefore want to take a different approach in the benchmarking initiative and provide participants who use SAP as their ERP system with a tool that can be used to extract and process the data required for benchmarking from the SAP system as fully automatically as possible via a modification of the A&K diagnostic plug-in.

A correspondingly convenient interface will be available for all companies that use DISKOVER SCO as an APS system (Advanced Planning & Scheduling System) for forecasting and scheduling.

Companies that work with other ERP systems without DISKOVER can of course also take part in the survey. These companies are provided with a data specification which they can use to extract the required basic data from their ERP system.

Focus on the essential, important and worth knowing

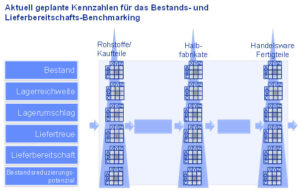

From today’s perspective, the plan is to record the key figures inventory, inventory range, inventory turnover, delivery reliability, delivery readiness and existing safety stocks for raw materials, purchased parts, merchandise and finished goods as well as – as far as possible – for semi-finished goods and to differentiate between ABC and XYZ criteria.

Clou 2: Company-specific target values for potential improvements

Thanks to the survey and evaluation technology used, the benchmark will not only conveniently record and process basic data, but also carry out potential assessments. The plan is to determine the inventory reduction potential and the safety stock to be recommended according to the forecast (as a comparative value to the safety stock actually stored in the system) on a company-specific basis and to make them available to the participating companies as individual parameters.

Are you taking part?

The preparation and implementation effort for this benchmarking initiative is considerable. However, we expect a large number of participating companies, so that the cost share of the individual companies will be less than € 2,500. Companies wishing to participate in the benchmarking initiative can pre-register free of charge and without obligation via the e-mail address benchmarking@ak-online.de and be placed on the further information distribution list.