By Anja Hartmann and Bernd Reineke

The supplier of foundry chemicals ASK Chemicals achieved better availability thanks to largely automated sales planning. Abels & Kemmner has optimized the sales and requirements planning process at the specialist supplier in Hilden.

Increasing customer demand and a simultaneous shortage of raw materials presented the supply chain of ASK Chemicals GmbH, one of the world’s largest suppliers of foundry chemicals, with a major challenge in the supply of raw materials for production. During the financial crisis, capacities were reduced in many places, which subsequently led to supply bottlenecks as incoming orders increased. The increase in sales hit most companies unprepared and the processes were not designed for such short-term fluctuations in demand. ASK was able to respond well to the market situation, as the sales and demand planning process had just been optimized with the support of management consultants Abels & Kemmner. The result today is largely automated and integrated sales and demand planning processes that have led to improved availability despite minimized effort.

ASK Chemicals GmbH is the preferred and innovative partner of the global foundry industry. Product-efficient problem solutions, tailor-made products and above-average technical service on site worldwide characterize the innovative company, which manufactures foundry chemicals and synthetic resins, among other things. The automotive industry and the mechanical and plant engineering sector in particular benefit from this.

Strong sales growth, lack of process adaptation

The years before the financial crisis were characterized by a sharp rise in sales and a corresponding increase in the customer base. As a result, the old structures for planning and controlling procurement and production were no longer suitable. However, there was no time to optimize the processes and develop suitable methods. A typical picture for rapidly growing companies. To remedy the situation, ASK Chemicals commissioned Abels & Kemmner to develop the new structures that had become necessary and to introduce suitable methods and tools.

In the past, processes at ASK Chemicals were characterized by ad hoc planning and control actions in order to be able to serve short-term customer orders. However, the high level of effort and coordination required to fine-tune production was not caused by a lack of planning expertise, which could have been improved by using a detailed planning tool. During the initial analyses, it became clear that these were more likely to be symptoms caused by higher-level planning. Current market developments were not consistently incorporated into the planning process. A lack of forecasts and insufficient security to cushion sales fluctuations led to the symptoms described above. It was therefore decided to fundamentally restructure the planning process and support it with suitable software.

Achieve maximum benefit with minimum effort

The aim of the new process was to keep the workload as low as possible while still achieving a good planning result. After all, the company did not want to create too much overhead for this additional planning, but wanted to remain as lean as possible. Abels & Kemmner’s proposal to determine future requirements as far as possible using statistical forecasts, i.e. to use software to automatically plan all the products to be scheduled, therefore came in very handy. The statistical forecasts should only be supplemented with sales information if deviations from the forecasts are to be expected. This means that the sales planner’s only task is to plan exceptions – which saves a lot of time and effort. This sounds good and is possible, but requires some framework conditions.

Additional requirements for the software

Since there is no rule without exception, it goes without saying that, in addition to automated scheduling, cases that cannot be predicted in a standardized way must also be taken into account. Every sales manager must therefore be able to enter promotions, new customer listings or cancellations by existing customers, for example. Other events that need to be planned manually are new products or product variants that cannot be forecast due to a lack of historical values, as well as discontinued products for which statistical forecasts are no longer calculated.

In order to carry out such analyses, software is required that makes it easy for the sales department to identify the exceptions. The software must therefore be able to describe the planning not only at component parts list level, but also at the customer’s item level. Mathematically and statistically, the software should also be able to automatically determine the most suitable forecast and safety stock procedures in order to achieve the desired delivery readiness with the lowest possible inventory. It is not enough to use just any forecasting method, but rather the forecasting method that delivers the optimum result should be used. This is a small but crucial difference that is all too often ignored in practice because there is often a lack of know-how about the different processes and the ERP systems used usually do not allow such variant tests.

Selected software convinces through methodological competence

There are not many software tools available on the market worldwide that support ERP systems in optimization, planning and scheduling. Of the systems available, Diskover SCO from SCT GmbH was chosen because it was the most convincing in terms of both programming technology and methodological expertise. The software has been developed using the latest Java technologies and can therefore be quickly and easily adapted to new requirements.

Special functions visible with a simple click

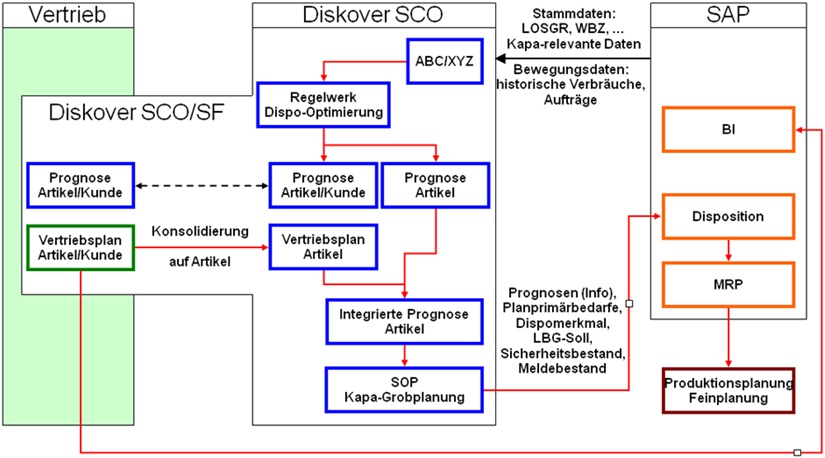

At the touch of a button, the methods offered can also be reduced to the possibilities of the SAP system being used, which makes both the high compatibility of Diskover SCO with SAP and the high level of technical methodological expertise itself easily visible, as a simple click reveals extended methods that lead to even better results in certain planning cases. If these special functions are not used, the data obtained from the SAP system via standard interfaces is analyzed in the set of rules integrated in Diskover SCO and returned to the SAP system with updated values. Here, Diskover SCO determines how the articles are to be set and how the sales figures are to be incorporated into planning and scheduling.

Using the Diskover Sales Forecast module, sales staff can record the exceptions at item/customer level as described above and thus incorporate them into planning. Regardless of location, data can be recorded worldwide and processed centrally. In the consolidated planning view, the additional requirements or sales corrections are visible and transferred to the requirements calculation. The end-to-end planning chain is completed by transferring the resulting planning figures and recalculated planning parameters (e.g. reorder and safety stocks) to the SAP system.

Anja Hartmann is Senior Manager Supply Chain at ASK Chemicals GmbH in 40721 Hilden.

Dr. Bernd Reineke is a consultant at Abels & Kemmner GmbH in 52134 Herzogenrath, Tel (0 24 07) 95 65-0, breineke@ak-online.de