Gremlin Electronics Inc. Optimizes planning and scheduling

Long replenishment times and issues such as container completion pose a challenge in planning. Together with a large number of product and product range changes, strong fluctuations in quantity and frequent changes in deadlines on the demand side, this can quickly lead to excess stock and / or a lack of readiness to deliver if planning and scheduling are “manual”. Gremlin Electronics Inc.*) in the UK has risen to this challenge as a trading company. Together with Abels & Kemmner UK, it has significantly improved both the planning and scheduling methods as well as the system support used in planning as part of a project.

Gremlin Electronics Inc. is one of the largest companies in the European electronics industry. Gremlin Electronics procures most of the components for its products, most of which are manufactured according to its own designs, in China. Delivery times are between 60 and 150 days. The transportation time alone for container shipments from Asia is approx. 6 weeks. As a result, Gremlin Electronics is faced with conditions on the procurement side that are reminiscent of the behavior of a tanker: long braking and acceleration distances as well as large turning circles.

The sales side of Gremlin Electronics, on the other hand, has to deal with market requirements that, to stay with the example, only a speedboat can fulfill. In order to always be able to satisfy customers with maximum delivery readiness and low warehousing costs, speed of response and flexibility combined with high quality are an absolute must.

Sluggish conditions in purchasing – rapid changes in demand

The long lead times on the procurement side require a sufficiently high level of stock to maintain delivery readiness: customers expect regular orders to be delivered within 24 hours. At the same time, orders must of course be placed well in advance for replenishment. Once “on track”, orders can no longer be stopped or only postponed. As a result, stocks are created that are no longer needed if the customer’s requirements change at short notice. This entails the risk of high depreciation and scrapping. In some cases, very high minimum order quantities further exacerbate this problem. The Chinese New Year, during which no goods can be received for three weeks, increases the inventory risk because orders have to be placed even earlier.

Conversely, the dynamics on the demand side and the sluggishness on the procurement market also mean that urgently needed goods cannot be obtained quickly enough. This results in expensive air freight costs to at least significantly reduce the transportation time. Failure to deliver to the customer on time can result in severe penalties, for example in the B2B sector.

The logistics costs also force us to complete the sea containers. This regularly requires the ordering of quantities that are not actually required due to the current demand situation.

Once the material is in the container, it is no longer returned if demand structures change, as the suppliers generally do not keep any stock and have no alternative use for the items. The effort required would be too great anyway. This applies in particular in the case of combined shipment, where a large number of suppliers are involved. Once the container is on board, it is definitely too late: there is no adequate response to avert the material that is not or no longer needed and thus the unnecessary build-up of stock.

A wide range of articles places high demands on article infeed and outfeed

Gremlin Electronics’ product range comprises a total of around 3,000 active sales items, of which around 600 are discontinued and 600 new items are launched each year. The consequences of the high run-out rate in combination with the complex planning task were in some cases high residual stocks, which led to write-offs and scrapping. Every company in a comparable position is probably familiar with this problem, as the planning of product launches and discontinuations is subject to very specific issues and is therefore anything but simple:

- Are there suitable predecessor relationships during start-up that can be used for statistical forecasting?

- If so, how is this information incorporated into the forecast for the new article?

- How do you organize the transition from predecessor to successor?

- If there are no suitable predecessor relationships, what will the start-up curve look like, both in terms of quantity and timing?

- Or how detailed can the sales department make a statement on expected consumption volumes, to the month or in terms of sales planning only as one figure per year?

- How is it possible to reduce replenishment stock to zero on the right date, if possible, but still be sufficiently ready for delivery by then?

- How much do you need to keep in stock for good customers?

- How large is the quantity that still needs to be kept in stock for spare parts requirements?

Immediate deliveries and actions with 20,000 order items daily must be mastered

Gremlin Electronics’ customers are spread across the specialist and wholesale trade. These B2B customers have requirements that would actually require a speedboat for planning and scheduling purposes. In particular, the demand for consistently high delivery readiness is underpinned by the fact that severe contractual penalties are imposed if the agreed delivery quota is not met.

Every day, around 20,000 customer order items are received with a delivery time of 24 hours.

Exception planning is an essential and difficult to manage part of the overall planning task. Exceptions are sporadically occurring, usually very large consumption quantities that do not have to be delivered within 24 hours, but after an agreed delivery time. Examples of such exceptional quantities, which are planned separately, are promotions and installations as well as initial equipment for new customers:

Promotions are occasionally postponed by the customer, the stock is then created too early, or individual items are removed from the promotion at short notice. The promotional quantity that is already in the warehouse or is about to be added unnecessarily increases the stock. The same applies to facilities. Large quantities must be supplied initially. As the customers’ set-up periods usually provide for all branches to be equipped at the same time, this results in very large fluctuations in demand. If the lead time or notice period is not adhered to, deadlines are postponed or purchase quantities are reduced, inventories increase accordingly.

In addition, returns and contingency planning play a not insignificant role in inventory build-up. Returns, which can result from discontinuations or product changes, for example, can sometimes be considerable in size and do the rest to make stock levels rise to an unpleasantly high level.

Allocation is an instrument for ensuring availability during promotions and customer deliveries. Reserving existing stocks ensures that other customer orders cannot use up existing stocks. This is always a problem if the customer only purchases 50 or 60% of the allocated quantity, but in the meantime additional material has to be ordered for regular deliveries. By the time the contingents that have not been accepted are released again, the orders for the other customer orders have long since been placed – resulting in excess stock. The seasonality of many articles seems almost incidental in view of this overall problem.

The aim: to improve delivery readiness while reducing costs at the same time

The aim of the project was to increase delivery readiness and at the same time reduce costs significantly and sustainably. The costs included:

- Inventory and warehousing costs,

- Air freight costs,

- Conventional penalties,

- necessary depreciation and scrapping.

The consultants from Abels & Kemmner examined both the planning and scheduling methodology and the existing system support in terms of their potential for improvement. They were then able to use the results to draw up recommendations for action and concrete steps for implementing efficient end-to-end planning.

The project started accordingly by recording the rough value streams as part of the as-is analysis. The requirements for the data to be provided, which was needed for various analyses, were also agreed right at the start. In addition to classifying items according to ABC and XYZ codes, these analyses were used to record and quantify the overall logistics system with its interdependencies and to identify the right variables for optimizing the overall system and setting them appropriately. The DISKOVER SCO simulation system was used to dynamically simulate the logistical behavior of the entire value chain and thus make it calculable. In this way, various logistical structures with different logistical performance levels and differentiated planning and control models could be simulated.

The fundamental question was which parameters could be used to achieve which delivery readiness and at what cost. The optimum process combinations and parameter settings in planning and scheduling were determined, taking into account batch size and minimum order quantity variations, replenishment times and other parameters within the various scenarios.

Parallel to the analytical considerations, the planning and control processes in place at the start of the project were fully recorded in interviews along the value chain. Following this survey and the initial results of the analyses, Abels & Kemmner conducted workshops with the Gremlin Electronics employees to identify delivery service brakes and inventory drivers. The story behind a specific overstock or non-delivery capability could thus be traced. This approach, which goes far beyond system and data analysis, enabled the consultants to identify the various causes of the overstocking and delivery deadline problems. Typical causes that are noticeable in a wide variety of companies across all industries are, for example

- Order out of caution because you have had a bad experience with the supplier,

- postponed actions,

- too euphoric start-up planning,

- Incorrect parameterization of the system, therefore possibly

- lack of trust in the system’s suggestions and manual override,

- unsuccessful balancing act between purchasing optimization (large quantity, low price) and inventory costs,

- incorrect master data,

- Specifications from other areas for scheduling.

At the same time, this picture of the causes makes it possible to draw up recommendations for action and to start implementing these recommendations immediately.

In the case of Gremlin Electronics, the aim was to get the tanker into the right manoeuvre earlier with an optimized preview and to optimize the timing and composition of its load. At the same time, the speedboat for supplying customers was to be further tuned so that it could meet the high demands of the market even faster and more reliably.

Simulatively optimized rules for planning and scheduling ensure a cost-effective supply chain

Conceptually, the project team has developed various recommendations for action. These were initially prioritized according to their efficiency, taking into account their interdependencies. This then resulted in the measures that were to be implemented. In addition, the decision was made early on to supplement the ERP system with the DISKOVER SCO software from SCT GmbH, a subsidiary of Abels & Kemmner, for sales planning and scheduling. This offers a wide range of additional functions for mastering the planning task as well as maximum transparency and support for the planner.

The introduction of integrated planning and scheduling was the core conceptual measure and thus the main pillar.

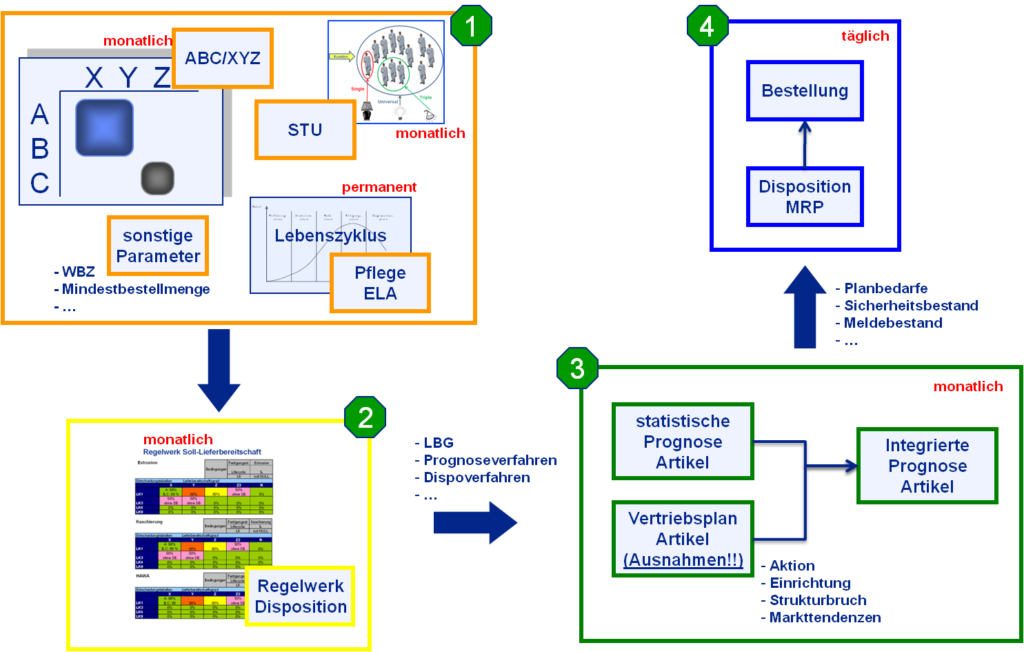

The end-to-end planning process starts with classification and continues with the scheduling rules. The latter influences both sales planning and the scheduling itself. Once the sales planning process has been completed, daily scheduling can begin and serve the market with speedboat power.

Nothing works without item classification

A key component of the new planning process is the regular classification of the complete product range according to

- ABC → economic importance,

- XYZ → Regularity of consumption (assessment of predictability) and

- STU → Number of customers per item and

- ELA (→life cycle)

These classification features not only provide transparency about the composition of the current range, but are also important parameters for deciding which processes and parameters should be set for which article. This ensures that all items are optimally positioned in planning and scheduling according to their respective life cycle phase and their consumption characteristics.

Automatic data maintenance for large article quantities

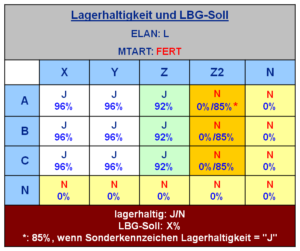

The item classification serves not only as a guide, but also as a concrete basis for the planning and scheduling of items and materials.

But which dispatcher can determine the optimum process and parameter settings for all their articles month after month and set them in the system promptly? Especially since the above-mentioned classification features are only part of the possible decision variables. Due to the large number of different input parameters, this optimization step can no longer be carried out manually.

The solution was to develop a set of rules that clearly defined how each item should be planned and scheduled. This set of rules is processed automatically by the system, making monthly updates possible even for very large product ranges.

After article classification and running through the MRP set of rules, it is now set how which article is to be planned and scheduled. Statistical methods are usually used here for live items in accordance with the ELA indicator. New product launches and discontinued products require additional information as a basis for planning, which primarily comes from sales and product management.

The planning of new launches (ELA = E) requires the best possible advance planning by sales, product management and field service. This planning is carried out on a monthly basis and per individual item; further differentiation by sector and customer is planned for the future. Where possible, system-supported predecessor-successor relationships are used for forecasting. Intensive monitoring of the start-up process with prompt correction of planning is firmly anchored in the process.

Live items (ELA = L) are primarily subject to statistical forecasts incl. Seasonal weighting. Due to the material properties or their sporadic use, some of them are only planned for specific orders. In this case, forecasts combined with high target delivery readiness would result in an excessive increase in safety stocks or unusable residual stocks. An outlier analysis ensures that one-off actions and other exceptions are not reflected in a distorted forecast.

Information on exception planning and actions could be processed automatically by e-mail

To ensure the convenience and acceptance of the sales staff and to link the new planning process with existing internal sales planning processes, exception planning such as actions with dates and quantities are recorded by the sales staff in Excel and sent to the DISKOVER service by e-mail. The sales employee automatically receives a message about the processing of his planned figures. These are imported into DISKOVER and the system sends a notification to the responsible purchaser that their items are in a promotion. At the same time, the campaign for the central disposition of Gremlin Electronics Inc. visible in the DISKOVER SCO interface for checking and approval. DISKOVER automatically checks whether or not the desired quantities are available on the desired date. If an item is unavailable, the MRP controller can double-click to switch directly to the affected item, check the planning and scheduling situation and take appropriate action.

An integrated forecast is now created from the available statistical information and the exception planning. This integrated forecast flows into the nightly MRP run and the multiple daily MRP net change runs together with the current stock, existing orders, purchase requisitions and customer orders.

When planning discontinued items (ELA = A), the aim is to systematically reduce stock to zero. In so-called phase-out rounds, which take place twice a year, various efficiency criteria are used to determine which articles are to be phased out. In addition, the developed scheduling and planning rules suggest item-specific changes. In the phase-out round, the date on which the item is to be phased out is then determined. In order to achieve the desired zero stock level while at the same time being ready for delivery by the discontinuation date, various replenishment strategies and procedures are used in replenishment.

An important part of the phase-out phase is the intensive monitoring of the phase-out process, combined with the prompt correction of planning and scheduling if the development of the inventory and demand situation does not proceed as expected.

It is planned to investigate the use of standard curves to support the discontinuation process at a later date. It can be assumed that the stock can be managed even more precisely up to the fixed expiry date.

Alert functions and automatic scheduling instructions support dispatchers

DISKOVER SCO provides dispatchers with a wide range of tabular and graphical support options as well as alert functions and reports. The reports in particular are a central component of daily work with DISKOVER. After processing the planned orders for which he receives proposals for the start/order date from DISKOVER, the scheduler systematically deals with the acute planning and scheduling problems, such as

- Shortfall within the WBZ,

- current shortages,

- Safety stock shortfall within the replacement period,

- acute shortfalls in safety stocks,

- Demand higher than forecast,

- Overdue orders / production orders.

Alert mechanisms ensure that items with the highest urgency are immediately highlighted and can be dealt with as required.

Exception planning such as promotions and facilities are displayed as an independent requirement element with quantity and date in MRP. This ensures that these requirements can be clearly distinguished and managed from regular requirements.

Another essential part of the daily scheduling work is the group scheduling. This takes into account the requirement that the order quantities of the individual components must be put together in the best possible way with regard to logistics costs and delivery readiness. A special optimization algorithm in DISKOVER SCO takes into account the various boundary conditions for determining the optimum combination of order quantities, e.g. within a container. DISKOVER calculates the individual components in the exact quantity required. Variables such as minimum order value, requirement and transport unit are calculation factors from which the system generates the order proposal.

The dispatcher can then check the proposed collective order, adjust it if necessary and release it. The transfer to the ERP system, which then processes the order as before, also takes place directly from here.

First results

As soon as implementation began, it became apparent that delivery readiness and stock turnover were increasing and inventories were falling. The gap between the sluggish large tanker on the procurement side and the highest speedboat dynamics on the customer side has become manageable at Gremlin Electronics. With improved delivery readiness and reduced inventory, Gremlin Electronics Inc. will continue to expand its recognized good service on the market for the benefit of retail partners and end consumers.

*) Names changed for company policy reasons.

Further information on this topic can be found here:

- Website of SCT GmbH

- Medion case study: EoL stockpiling for spare parts supply

- Case study: Optimization of delivery readiness, inventories and costs at the medical equipment supplier Serag-Wiessner

- Combination therapy against inventory pain at Hansa AG