By Frank Derlien, Carsten Hense*) and Andreas Kemmner

In addition to the production control system, Montblanc Goldfed Manufacturing was given a new production layout with the aim of significantly reducing throughput times and work in progress. The lean strategy is taking shape.

The spring unit production process is very complex. It resembles a manufactory with flow production. The spring units are manufactured exclusively by hand. The production process consists of up to 35 different work steps that require the highest manual precision. For example, every single nib at Montblanc is sharpened, set and written by hand.

The very high number of variants and the daily changing bottlenecks in production due to demand are now mastered quickly and efficiently using electronic planning boards. This was a basic prerequisite for the reorganization of the Goldfedermanufaktur that has now taken place.

Analysis of the current situation

As always, the concept was preceded by a detailed analysis of the current situation. Due to the complexity of Montblanc production and the task at hand, a lot of time was deliberately devoted to this phase. This proved very successful, as the rough and detailed concepts were developed and approved in a relatively short time. The focus was on detailed analyses of material flow, value stream and layout. This was based on both historical data and planning data for future periods.

Material flow optimization

In recent years, Montblanc’s growing departmental structures and new investments had meant that the flow of materials in the department no longer met the requirements for uniform material flows. The challenge was to optimize the material flow of the three production groups within the existing, relatively cramped premises, but also to support the desired production segmentation.

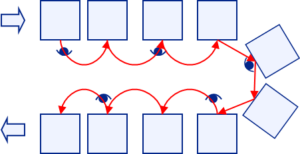

The actual material flow in the three production groups was designed and implemented in a so-called U-layout. A material flow in a U layout with a central material supply rail was selected. This solution requires considerably less space than a “classic” U-layout approach. The realized approach shows slightly longer distances for Montblanc employees to other workplaces compared to the first approach. However, it scores points in terms of even shorter material transport routes, greater material transparency with regard to circulating stocks and can supply all workstations centrally below the material supply rail with electricity, exhaust air, etc. (Figure 1).

Outgoing goods collection point

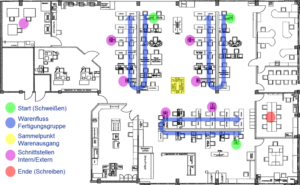

The material flow in the new U-layout begins in Montblanc production at the welding workstation with the welding of an iridium ball. After the production order has been processed at other workstations, the material leaves the department for the first time after the presetting operation. The springs are tumbled (deburred) in the vibratory grinding department. There are a total of three interfaces to external departments during the entire production process (vibratory finishing, rhodium plating, washing). A central “outgoing goods” collection point was created for these outgoing goods. It is centrally located in the immediate vicinity of all three Montblanc production groups and can be reached within a short distance. This collection point is divided into three areas: Each external processing area has its own area from which the employees collect the material independently.

Collection points Montblanc incoming goods

After external processing, the material is transported from these departments back to the specially created staging areas (internal/external interface) in the Goldfedermanufaktur. These staging areas are located directly next to the subsequent work steps, making the material waiting for further processing immediately visible. The staging areas and the central material supply rail thus ensure maximum transparency in the production groups with regard to the material waiting to be processed.

In addition to the last step, the so-called writing, in which Montblanc ink is used to test whether the nib glides “effortlessly” over the paper and thus meets the high quality requirements, only the polishing step was not integrated into the U layout. As polishing is the last operation of the second internal segment, the additional transport distances are very short and therefore acceptable for the design (Figure 2).

Production segmentation

The central element in being able to significantly reduce throughput times and work in progress is the reorganization of Montblanc production into manufacturing segments. The new material flow and the new U-layout take this reorganization into account and support it. Compared to the previous workshop-oriented production, production in segments (production blocks) has drastically reduced both throughput times and work in progress.

Structure of block production

During the Montblanc production process, the nib assemblies have to leave the gold nib factory several times for further processing in other departments (vibratory finishing, rhodium plating, washing). Due to this non-resolvable structure, the segment boundaries were defined in a quasi “natural” way: they are always located where the spring units leave spring production (end of segment) or are fed back into spring production (start of segment). Between these “natural” segment boundaries, it was possible to create continuous flow production.

The new Montblanc production structure therefore has four internal and three external segments. A production order must run through all operations of a segment (internal or external) within one working day. The ideal lead time for a production order would therefore be seven working days instead of the previous average of 33 working days.

However, the target for the throughput time is ten working days: Buffer stocks are required within the segments at sensitive workstations in order to avoid losing capacity at other workstations within the process chain due to machine downtime. Here, Montblanc clearly prioritizes employee utilization and productivity over throughput time and inventory reduction. For the go-live, the buffer stocks for the initial configuration of segment production were even set slightly higher to ensure the smoothest possible start. The buffer stocks are gradually removed from the system during further operation.

The production segmentation clearly limits the circulating stocks in gold nib production. Each production segment only ever contains production orders in the amount of the daily capacity of the production group. The work in progress is therefore calculated from the net lead time of all segments multiplied by the daily capacity per production group plus the daily capacity per production group. of the buffer stocks. Compared to the previous circulating stocks, between 50 and 65 percent less material is now required in the process (Figure 3).

Incoming orders and capacity requirements

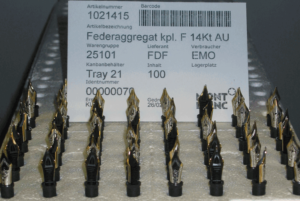

The 14- and 18-carat Montblanc gold nibs wait in polystyrene trays to be used at the tip of the fountain pen in the final assembly of the writing instruments. However, before they get there, they have undergone a complex, multi-stage, time-consuming and labor-intensive production process (image).

Complex production process through to final assembly

In view of the complexity of production, optimizing employee deployment (capacity utilization) while reducing throughput times and inventories posed a major challenge for production management at Goldfedermanufaktur.

In order to level out and stabilize capacity utilization in gold nib production at Montblanc in the future, fluctuations in incoming orders (fluctuations in demand) must no longer spill over into the three production groups. To prevent this, the current production control system was expanded to include a Heijunka control system.

Heijunka

The term Heijunka refers to the process of smoothing required capacity requirements. Smoothed production is considered to be the most efficient and cost-effective method of production. The analyses of the incoming order data carried out at the start of the project showed very high fluctuations in the daily Montblanc incoming order quantities within the production groups: from up to seven times the daily capacity limit to no incoming orders at all over several days. If an overall analysis was carried out across all three production groups, the periods with no incoming orders at all were significantly reduced. This made it clear that, in addition to leveling incoming orders and capacity utilization within the production groups, the Heijunka control system also had to be used for balancing between the production groups.

Clocking

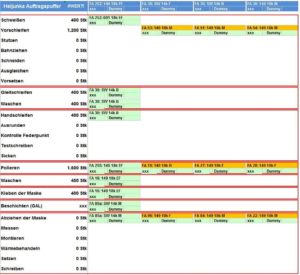

Each Montblanc production group has its own Heijunka board. This is populated with the daily incoming orders by production control. The basis for the daily scheduling of production orders in the production groups from the Heijunka board is the weekly employee scheduling. The number of spring units that can be processed represents the cycle at which production order quantities must be loaded daily from the Heijunka board to the first operation of the production groups.

This “cycle” (number of spring units to be processed daily) is now tracked by the production groups from production segment to production segment. With a throughput time of one working day, the quantities are “clocked on” from segment to segment. The buffer stocks are of course taken into account. Each production group organizes the organization of work within the segments and the staffing of the corresponding workstations for itself.

Throughput times and work in progress are documented and historicized daily for each production group, each production segment and each individual workstation and evaluated in monthly reports.

Leveling between production groups

If there are no more orders on the Heijunka board or if the Heijunka board is overflowing with orders, leveling within the production group is no longer sufficient. If this is the case, a comparison must be made between the three production groups.

Each Montblanc production group manufactures a different product range. As a result, the production orders cannot be exchanged between the groups at will. There is only one product group that can be produced in all three production groups. This product group is a volume model with regular consumption behavior and thus facilitates the balance between the groups. Compensation is always necessary,

if incoming orders are so low that “lost” capacity must be expected in a group. In this case, orders of the volume model are transferred from the Heijunka board of one production group to the other production group. However, it can also happen that a Heijunka board “overflows” due to a large number of incoming orders. If the order backlog in the Heijunka board exceeds five working days, production orders are transferred to the other two production groups.

Visualization in the Heijunka board

The Heijunka board for leveling and smoothing the production segments was implemented within the existing electronic planning boards in gold spring production. All the necessary calculation mechanisms are performed automatically by the electronic system. Instead of manual boards, the information is displayed on large flat screens distributed throughout the gold nib production area. In this way, it was possible to combine visual management with efficient operation (Figure 4).

The new layout, the new material flow, production in segments and the Heijunka control system have now proven their worth in the Montblanc gold nib factory. The new gold nib manufactory has thus become another key design element of Montblanc’s lean strategy.

*) Frank Derlien is Head of Nib Production and Carsten Hense is Head of Production at Montblanc Simplo GmbH, Hamburg