Increasing material efficiency requires a holistic approach

High material efficiency is one of the most important competitive factors. For this reason, the Federal Ministry of Economics and Technology supports companies in thefinancially in identifying the corresponding potential forpotential.

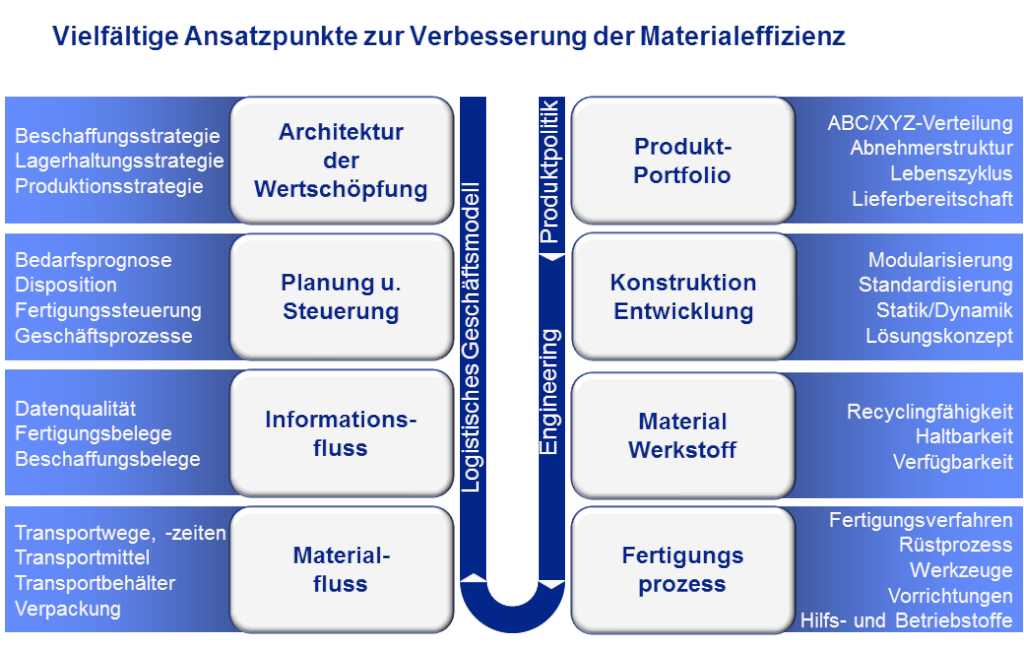

The purely technical aspects of product development and production are often looked at first. There is much more potential in the holistic design of the entire value stream than in pure technology.

Increasing material efficiency is one of the most important issues for German companies in the coming years. The Federal Ministry of Economics and Technology (BMWi) has also recognized the economic importance of improved material efficiency and offers small and medium-sized companies financial support for this. To this end, the innovation vouchers issued by the BMWi can also be used for qualified advice on increasing raw material and material efficiency. The BMWi covers 50% of the costs for consulting by a consulting firm authorized by the BMWi. According to the BMWi, the external experts will then identify material losses in products and production and make concrete suggestions for improvement.

What becomes apparent time and again in practice: In most companies, measures to increase material efficiency are limited to individual areas of the value stream, namely the technical or very material-related aspects of production. For example, the reduction of waste (quality scrap) or the optimization of offcuts (flat scrap) through more efficient cutting or punching. Material-saving designs – keyword: lightweight construction in the automotive industry – are also often taken into account. The focus is therefore mostly on the processes in the machines or on the handling of the materials themselves. However, the potential for increasing material efficiency is far from exhausted. There is much more untapped potential for increasing material efficiency in the planning aspects of the value stream – i.e. everything that happens around the machine. Just a few examples:

Internal vs. external diversity

The question of the number of product variants, for example, has a very significant impact on material efficiency. A distinction must be made between internal and external diversity. Naturally, customers should be able to choose from a wide variety of products. However, the aim must be to keep internal diversity as low as possible through a high proportion of multiple-use parts. This is because an increasing number of component variants increases the number and quantity of raw materials, production and assembly parts and assemblies required. A smaller number of variants improves all these factors and also leads to better demand-oriented planning of products and production.

Component warehouse vs. finished goods warehouse

If product variants are implemented with as many standard components as possible and the final variant design takes place at a later point in the value stream and is assembled according to customer orders (postponed manufacturing), this makes a double contribution to material efficiency: The high level of multiple use directly reduces the risk of scrapping due to requirements that are no longer needed (obsolescence risk). The late creation of variants reinforces the effect, as the stocks required for reasons of delivery readiness and the associated risk of scrapping can be reduced.

Machine utilization vs. demand

If the machinery used causes high set-up costs and possible running-in scrap, large batches are often produced for reasons of cost and material efficiency. Large batches may also be required if production capacity is limited, because no capacity should be lost for set-up. However, large production batches lead to significantly higher inventories and thus to a higher risk of scrapping. High circulating stocks also occur when more is produced than necessary for reasons of capacity utilization. Project analyses by Abels & Kemmner have repeatedly shown that the annual inventory-related material efficiency losses are between 5.5% and 9% of the stock. This means that more material efficiency can quickly be lost through inventory build-up than has been gained elsewhere through measures to reduce material loss.

In the 11 material efficiency projects funded by the BMWi and carried out by Abels & Kemmner to date, a reduction in material losses of up to 29% has been achieved, which corresponds to annual savings of several hundred thousand euros.