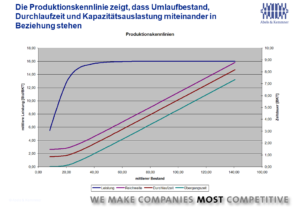

Production characteristic curves depict the interdependencies of the logistical target variables of performance, throughput time, transition time and range depending on the stock level in a work system. This makes them useful for planning, managing and controlling the logistical positioning of a production system. The production characteristic curves show how a change in the average inventory affects the performance, throughput time and range of a work system under otherwise unchanged boundary conditions.

Every change to one of the production characteristics results in significant changes to the other logistical target values: if you reduce stock levels, for example, throughput times will also decrease. However, if you reduce stocks too far, there is a risk of disruptions in the material flow and thus a loss of performance.

The basic form of the production characteristic curves applies to any production system. However, the specific characteristics of the curves depend on different framework conditions such as the capacity, the orders to be processed (in particular their average value and their scattering of the order time) and the integration of the system into the material flow.

Our tip:

With the help of production characteristic curves, you can adjust your production between the targets of adherence to delivery dates, throughput time, capacity utilization and work in progress in order to achieve a stable production control situation. It is important to maintain the “operating point” once it has been defined through targeted and short-term interventions in the available capacity.

Further information on this topic can be found here: