By Andreas Capellmann (SCT GmbH)

Precise forecasting of sales potential and optimal planning of procurement and production is crucial for the often seasonal and varied clothing industry. Anita Dr. Helbig GmbH has therefore been using the Advanced Planning and Scheduling (APS) software DISKOVER SCO for around four years and has been able to significantly improve its stock situation and delivery readiness as well as achieve lasting cost savings.

Anita Dr. Helbig GmbH manufactures and sells corsetry and swimwear in large cups and sizes for expectant and nursing mothers as well as for women who have undergone breast surgery, for young fashionable women with large bust sizes and strong women who need relief. As a stock manufacturer, the bodice specialist relies on good planning quality in order to avoid unnecessarily high stock levels while still being able to deliver the items ordered by customers on time. A particular problem for Anita Dr. Helbig is that the number of new models and/or color designs is constantly increasing. This increases the number of planning items accordingly.

Anita Dr. Helbig GmbH manufactures and sells corsetry and swimwear in large cups and sizes for expectant and nursing mothers as well as for women who have undergone breast surgery, for young fashionable women with large bust sizes and strong women who need relief. As a stock manufacturer, the bodice specialist relies on good planning quality in order to avoid unnecessarily high stock levels while still being able to deliver the items ordered by customers on time. A particular problem for Anita Dr. Helbig is that the number of new models and/or color designs is constantly increasing. This increases the number of planning items accordingly.

Variety of variants increases irregularity

The greater number of variants also increases the irregularity, which makes it all the more difficult to estimate the sales figures for each planning item. In the past, sales figures were calculated by averaging past values. As a result, product trends were only recognized very late and the quality of planning declined as the product range changed more frequently. This led to increased stock levels for non-turners and a lack of availability for items in high demand, which is particularly annoying for sales and customer satisfaction.

Unsuitable tools lead to forecasting errors

To improve the situation, Anita Dr. Helbig worked with a management consultancy for supply chain optimization to find a suitable new organizational form of planning. It quickly became clear that this could only be achieved with suitable software tools. Initially, they were still looking for solutions to map the extended tasks in the ERP system used, but it quickly became clear that ERP systems are not special systems for forecasting and scheduling. You can perform these tasks in a rudimentary way with them, but the result is far from optimal. There are practically no automatic mechanisms for the continuous optimization of scheduling parameters.

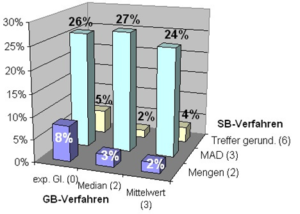

Use the right forecasting methods All ERP systems that were analyzed, for example, exclusively use methods that assume normally distributed demand, such as mean value methods or exponential smoothing. However, this is almost never encountered in practice. This leads to systematically incorrect demand forecasts and inventory errors of up to 40%.

In addition to the higher-level ERP system, you also need more precise special tools in order to be able to plan optimally. These precision tools for dispatchers are also known as advanced planning and scheduling software, or APS software for short.

Simulation functions illustrate the difference

One of the most important criteria for Anita when choosing the APS software was therefore that the tool had the necessary range of forecasting methods and parameters to be able to select the most suitable one for the item in question and thus run a customized demand forecast. In addition, the software should have detailed simulation functionalities that can be used to run through various scenarios and precisely predict the effects of the respective processes on delivery readiness and inventory levels.

Other requirements that Anita placed on the APS software were:

- Dimensioning of suitable safety stocks to cushion sales fluctuations and supply bottlenecks

- Possibility of automated determination of sales expectations without manual effort.

- Forecasts on a weekly basis

- Planning on stock item, i.e. items must be plannable by color, size and cup size

- Flexible and automated adjustment of logistical parameters, such as batch sizes

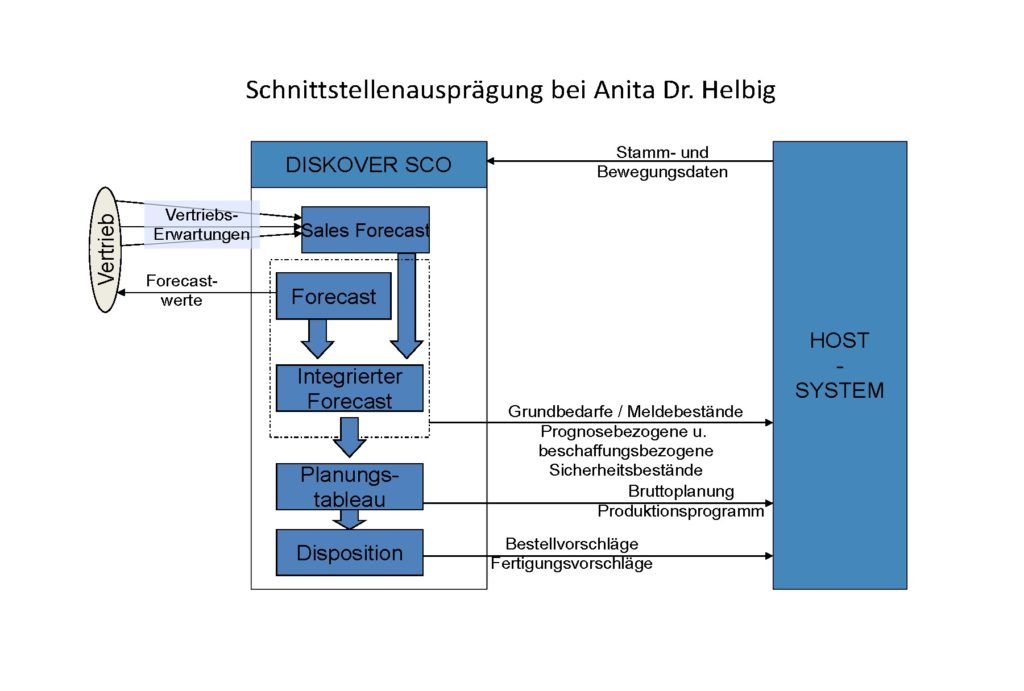

- Interface from and to the ERP system based on IBM AS400

Accuracy of demand and sales planning significantly increased

In the search for a tool that could meet all of these requirements, SCT GmbH and its DISKOVER SCO supply chain optimization software was found. “We have been using DISKOVER SCO successfully for around four years now. With this precise scheduling tool, we have been able to significantly increase the accuracy of our demand and sales planning and thus considerably improve our stock situation and readiness to deliver – despite an increasing number of variants,” explains Felicitas Heid-Davignon, Head of Production & Logistics at Anita Dr. Helbig GmbH in Brannenburg.

Step by step introduction

At Anita Dr. Helbig GmbH, the APS tool from SCT was initially only used to optimize demand forecasts. However, special requirements, such as the regular adjustment of batch sizes, e.g. taking packing units into account, could also be solved and implemented within a short time. In the final expansion stage, the dispatchers now also use DISKOVER as a front end for daily scheduling. “Thanks to the program’s bill of materials resolution, the entire material planning is also much closer to demand and thus also enables the same savings in this area. In addition, the transparent link between material usage and finished parts provides a whole new level of transparency,” says Ms. Heid-Davignon. This transparency ultimately led to Anita being able to initiate measures to increase material efficiency, which reduced material waste by a total of 29%. The result here: annual savings of several hundred thousand euros.

Lower costs and effort for software solution

However, DISKOVER not only reduces the effort involved in operation and thus enables the continuous optimization of the supply chain in day-to-day business. Thanks to the rental licence model and continuous delivery, DISKOVER also minimizes the costs and effort involved in purchasing, maintaining and operating the software solution. Instead of massive initial investments for runtime licenses, SCT customers only have to pay a much lower monthly fee for the use of DISKOVER SCO. And thanks to Continuous Delivery, all new software developments reach users in the shortest possible time. As direct user support, maintenance work and updates are carried out by the SCT service center, the customer’s IT department does not have to provide any specialist support for the system or its users. Hidden in-house costs, which are often forgotten when calculating alternative models, are therefore not incurred.

Support in day-to-day business

Here, the APS software is characterized by extensive simulation calculations that run automatically in the background and continuously optimize planning and scheduling settings and decisions. In this way, even less technically and professionally experienced users benefit from the high forecasting accuracy and scheduling precision. Companies can enjoy sustainably reduced inventories while ensuring the necessary readiness to deliver.

Time for the essentials

Many planning and scheduling processes can also be automated, rationalized and made reproducible with DISKOVER SCO. This ultimately leads to an improved disposition without major effort. Instead of constantly chasing after day-to-day business, dispatchers finally have more time for the important things, such as more intensive supplier integration, which promises further savings.

Permanent cost savings

The cost savings achieved through the use of DISKOVER SCO are not used up by the ongoing license costs for the software, but are permanent. After all, inventory reduction is not a one-off effect, but an ongoing one: by reducing their stock levels, companies can save six-figure storage costs every year. Ms Heid-Davignon also confirms this: “Without optimization software, these annual costs would be recouped very quickly. And other positive effects that we achieve through the use of DISKVOER, such as less planning effort, better delivery readiness and information capability, are not even taken into account.”

Further information on this topic can be found here:

- Case study DISKOVER in practice: Mehler Texnologies GmbH

- Best practice rules for efficient sales forecasting