Raw materials are becoming scarce and customer demand is growing – this is a major challenge for any supply chain. ASK Chemicals, one of the world’s largest suppliers of foundry chemicals, has responded well to this difficult market situation: With DISKOVER SCO for forecasting and group scheduling, the company with its main plant in Wülfrath was able to optimize its sales and demand planning process. In conjunction with the leading ERP system, this has resulted in largely automated and consistent sales and demand planning processes that lead to better results despite minimized effort. As a result, it was possible to increase delivery readiness while reducing inventories.

ASK Chemicals GmbH employs 1,800 people and manufactures customized products for the foundry industry as well as synthetic resins and specialty products worldwide. The innovative company is also characterized by on-site technical services. The product portfolio includes foundry additives such as binders, coatings, feeders, filters and release agents as well as metallurgical products such as inoculants, inoculation wires and master alloys for iron casting. ASK Chemicals therefore offers a broad product portfolio with many variants. If such a broad portfolio has been compiled from several companies, as in the case of ASK, this makes it even more difficult to manage.

More harmony in the planning process

ASK was formed in 2010 from a joint venture between Clariant and Ashland. Fabian Gasczak, Manager Supply Chain Planning at ASK Chemicals at the main plant in Wülfrath: “The heterogeneous structures for planning and controlling procurement and production had to be adapted to the new company.” In order to be able to meet short-term customer orders despite the strong growth in demand, ASK Chemicals’ processes were characterized by ad hoc planning and control actions. The reason for the high level of effort and coordination required to fine-tune production lay in the higher-level planning, as current market developments were not consistently incorporated into the planning process. The resulting lack of forecasts and insufficient security to cushion sales fluctuations ultimately led to the high planning costs. Gasczak: “That’s why we decided to fundamentally redesign the planning process and support it with suitable software.” Following a comprehensive analysis, which Abels & Kemmner supported in an advisory capacity, suitable methods and tools were introduced at ASK Chemicals, which cemented the new structures that had become necessary. Since then, DISKOVER SCO has been optimizing planning for forecasting and network scheduling, especially as the tool is specially designed for optimizing the scheduling of complex supply chains.

Better results with less effort

The planning process had to be adapted accordingly in order to achieve better planning results with minimal effort for planning and control. Gasczak explains: “Statistical forecasts should be used to plan future requirements – i.e. all products to be planned – as far as possible automatically using software. Sales information should also supplement these statistical forecasts in order to be able to include current market developments in the forecasts. If the comparison of this data is largely automated, the sales planner only has to take care of the forecasts with deviating data – which saves a lot of time and effort.” However, this also requires the creation of suitable framework conditions.

Exceptions confirm the rule

Because here, too, there is no rule without exception. This means that scheduling cannot be 100% automated; special cases must also be taken into account. New products and product variants, for example, have no historical values and therefore cannot be forecast. They have to be planned manually, just like discontinued products for which statistical forecasts are no longer calculated. It must also be possible to record promotions or new listings and discontinuations by customers.

More differentiated planning levels and statistical procedures

In order to carry out precise analyses, software is also required that makes it easy for the sales department to identify these exceptions. The tool must therefore also be able to describe the planning at the customer’s item level and not just at the BOM level of the components. Mathematically and statistically, the APS system should also be able to automatically determine which forecasting and safety stock procedures are best suited to achieving the desired delivery readiness with the lowest possible stock levels. In practice, this selection is usually not optimal because there is a lack of know-how about the different processes and the ERP systems used usually do not allow such variant tests.

High planning quality thanks to various algorithms

Now you might think that so many special functions do not necessarily increase planning efficiency. However, this is precisely the case: analyses at ASK Chemicals showed that the proportion of automatically forecast articles is very high. For example, a number of items are planned based on consumption using reorder point procedures – particularly in the area of raw materials. With the help of the sales and forecast figures, new reorder points are always determined and transferred to the SAP system via standard BAPIs. Other articles are planned with planned independent requirements. For these items, the pre-planning values are transferred to the SAP system with the identified strategy group. The few remaining exceptions can be conveniently planned “manually” by the sales department from anywhere in the world. The integrated optimization algorithms used in the simulation also result in very high planning quality. The planning situations of the past are recreated and alternative methods for determining safety stocks, forecasts and scheduling as well as their parameters are applied in order to ultimately arrive at the best possible scheduling.

Flexible software with ease of use

Only a few software tools in the world are able to optimally support ERP systems in the optimization of planning and scheduling. “We opted for DISKOVER SCO from SCT GmbH because this system was the most convincing in terms of both programming technology and methodological expertise,” explains Gasczak.

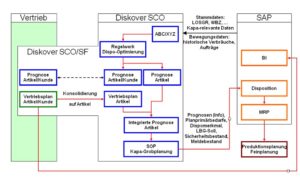

“The APS (Advanced Planning and Scheduling) software that we use for sales forecasting and group scheduling has been developed using the latest Java technologies – so it can be adapted quickly and easily to any new requirements.” At the touch of a button, the methods offered can also be reduced to the possibilities of the ERP system being used. This makes the high level of compatibility with ERP systems and the high technical methodological competence of the APS tool easily visible. With a simple click, you can even select advanced methods that lead to even better results in certain planning cases. In such a configuration, users even use the simulation tool as a front end. However, if the user dispenses with these special functions – and this is the case with ASK – the data that DISKOVER obtains from the ERP system via standard interfaces can be analyzed in DISKOVER SCO’s integrated set of rules and returned to the ERP system with updated values. This means that users can continue to use their already trained ERP user interfaces. However, it is no longer determined in the ERP system, but in DISKOVER SCO, how the articles are to be set and how the sales figures are to be incorporated into planning and scheduling.

Consistent planning chain increases efficiency

ASK Chemicals also uses the DISKOVER module ‘Sales Forecast’. As a front end, this module enables sales staff to record their forecasts at item-customer level and thus incorporate them into planning. Incidentally, this is browser-based worldwide and is processed centrally – regardless of location. The additional requirements or sales corrections are then visible in the consolidated planning view and are transferred to the requirements calculation. The end-to-end planning chain is completed by transferring these planning figures and recalculated planning parameters (e.g. reorder and safety stocks) to the SAP system.

Fabian Gasczak is therefore certain that ASK Chemicals has made the right choice with DISKOVER: “The quality of planning has clearly improved thanks to the use of this tool. We can now plan much more flexibly and have been able to minimize the planning effort in our operational business. This has significantly increased our profitability and we have been able to achieve an industry-leading position. The automotive industry and mechanical and plant engineering in particular benefit from this.”

Further information on this topic can be found here:

- Mehler Texnologies optimizes supply chain with APS tool

- Customized disposition for bras