Strategy: Checklists for optimizing supply chain management

There are many ways to acquire knowledge and find new inspiration. However, hardly any other method is as efficient as checklists, because they can also reflect your own situation. Abels & Kemmner has compiled new checklists on the subject of supply chain management. They are presented for the first time in LT-manager.

Dispatchers and logistics managers in work preparation must ensure that every part, no matter how small, is available at the right time. To this end, they sometimes manage tens of thousands of warehouse and JIT items from goods receipt through various production stages to the finished goods warehouse and finally to dispatch to the customer. This task alone is very complex. If you then also want to achieve perfect delivery readiness of 98 percent, for example, without exploding stock levels, it gets tricky. The task is to manage an abundance of parameters for this immense number of articles and to forecast as accurately as possible how demand will develop. Not everything can be delivered and produced just-in-time. For example, you also need to know what the sales forecast for individual items looks like. It can already be seen here that disposition is not an easy undertaking because there are an enormous number of interdependencies to consider.

The risk: Summarizing parameters

But even if all these disturbance variables from other departments are ignored, scheduling remains highly complex. This can be seen from the amount of master data required for ERP systems alone: Depending on the cut of the article, you have to take care of up to 130 logistical parameters. If you imagine this as a mathematical equation, it is easy to understand that you cannot calculate it in your head. However, major mistakes are made when individual parameters are combined for the sake of simplicity. For example, safety stocks for fluctuating demand, safety stocks for fluctuating production times and safety stocks for fluctuating delivery times of the upstream suppliers are mapped in a common safety value. Cumulatively, this can only lead to more stock. Strongly oscillating graphs with many different peaks become curves until you finally arrive at a “smooth” forecast, which, however, only covers up the problems and ends up costing a lot of money.

If you want to check whether your supply chain management is well adjusted, you can read specialist journals and books, research on the Internet or attend lectures and seminars. However, if you also want to reflect on your own supply chain situation, the only other options are expert discussions or checklists. Expert advice is expensive. The new supply chain checklists published by management consultants Abels & Kemmner, on the other hand, are available free of charge. They therefore offer a perfect introduction to self-reflection. They were designed to assess the supply chain competence of both manufacturing and trading companies and were developed on the basis of many supply chain optimization projects.

Checklists for stocktaking

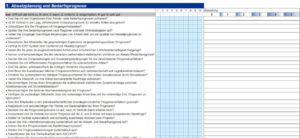

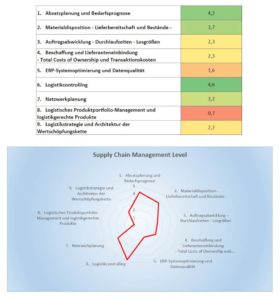

The checklists are divided into nine areas of competence, which are assessed individually. Furthermore, the inventory is summarized in a network diagram. A total of 229 questions are asked, which have to be evaluated in six categories similar to the school grading system. Topics covered include sales planning and demand forecasting, materials planning, order processing, procurement and supplier integration as well as ERP system optimization and data quality. The checklists are supplemented by questions on logistics controlling and network planning. Product managers will also find questions on logistical product portfolio management and logistics-compatible products. The checklists are rounded off with management questions on logistics strategy and the architecture of the value chain.

The comprehensive data entry form is provided as an Excel spreadsheet and can be completed by the companies themselves. The assessment shows directly in which of the examined areas of expertise there is a need for action and which detailed tasks the company should work on. Interested companies can request the data collection document from the provider and, in the current pilot phase, will receive free expert feedback by telephone when they return the completed questionnaire.

Prof. Dr. Andreas Kemmner on the new supply chain checklists: “The benefits are manifold. They help you not to forget anything. They even help to free you from the mental baggage of having forgotten something by ticking it off. They also provide structure. It is easy to get started with the topic, as you don’t have to think your way through specific things, but are given a comprehensive overview of a topic using ready-made questions. This saves a lot of time and thought and even extensive topics can be worked through completely.”

Ultimately, by working through the checklists, companies also increase efficiency and even save costs should an external consultant be required, as the status quo analysis can be brought to the point much more quickly.

Questions uncover optimization potential

The first twenty questions in the sales planning and demand forecasting checklist provide an initial impression of how you can use the questions to put your own supply chain management to the test.

The questions start simply: “Are you satisfied with the results of your sales or demand forecasts?” You can decide on a scale from 1 to 5. While many dispatchers may still give a 2 here because they are satisfied with what they can achieve under the given circumstances, the second question can quickly slip into the negative range. The question here is whether the sales department is able to provide differentiated sales forecasts for individual items. This is where the dependency of dispatchers on other departments becomes directly apparent and an overall optimized logistics management is still a problem in many companies. It continues with questions such as “Do you support your forecast with historical data?” or “Do you record predecessor-successor relationships of articles in order to improve the quality of new part forecasts?” These questions show that there are many ways of determining forecasts. Each of the questions always indicates a potential for optimization that needs to be exploited.

If you calculate that you need one minute to think about and answer each question, you will spend around half a day on the questionnaire. That’s a lot of time. But if you look at the potential that can be harnessed in logistics, these hours are always well invested, because in some cases, decisions are made in scheduling for which managing directors of large companies have to obtain approval from the supervisory boards. After all, we are often talking about millions that are tied up in stock and work in progress, and the optimization potential is often in the double-digit range. So if you have 10 million euros in inventories, you can quickly free up a million in capital. It is therefore surprising that many managing directors do not invest significantly more in optimizing their supply chain.

The checklists are therefore not only of interest to schedulers, but also to managing directors, plant managers and executives in manufacturing companies in the areas of logistics, purchasing and procurement, production/process management, production as well as controlling and general corporate planning and management.