HANSA-FLEX – how to solve any hydraulic problem within 24 hours and still reduce stocks and scheduling costs

Edwin Maringka, Dr. Bernd Reineke[1]

HANSA-FLEX AG, headquartered in Bremen, has developed from a spare parts supplier for hose lines to a global player in fluid technology. With 400 branches and 303 service vehicles, the company supplies its customers in 37 countries. HANSA-Flex manufactures and supplies over 100,000 different items with approx. 35,000 SKUs. There are around 3,500 items in each branch. The 3,400 employees of HANSA-FLEX AG generated an impressive turnover of € 410 million in 2015. The key logistical success factor for the hydraulics experts: the products are “guaranteed available”!

In the right place at the right time

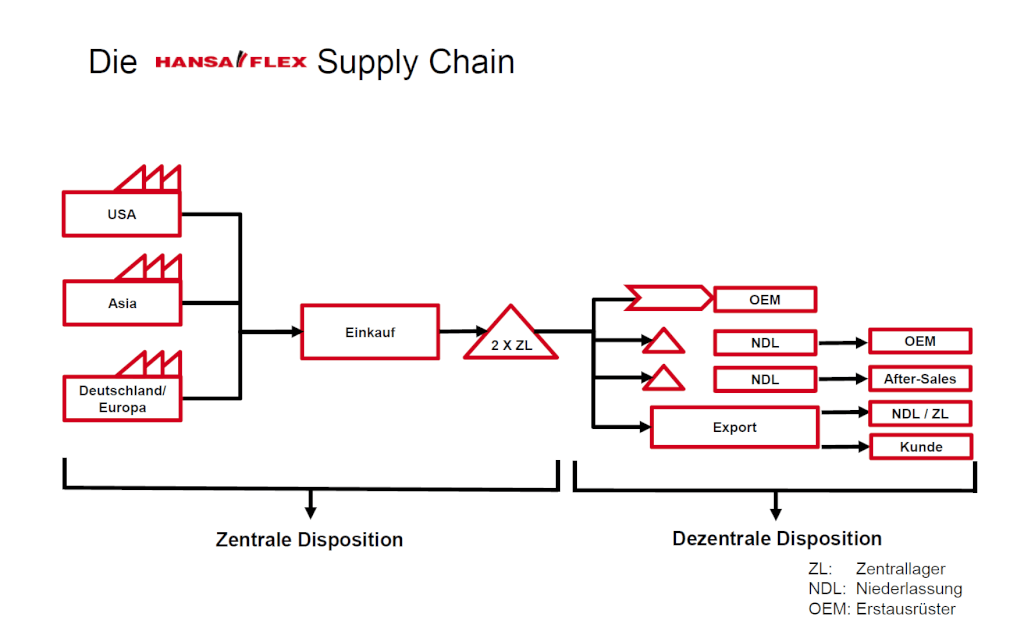

This “guaranteed availability” naturally brings with it a number of logistical challenges that need to be mastered. The high proportion of direct sales with such a wide range of variants requires not only the ability to react quickly, but also an economical mix of centralized and decentralized warehousing. This is the only way to guarantee high availability.

The crux of the matter, however, is that the portfolio structures for the various branches have to be adapted to the respective requirements. Or to put it another way: The right items must be in stock in the right quantity at the right location.

A balancing act – fluctuations are no fun!

To make matters worse, the OEM sector places high demands on quality and price. In the course of this, global sourcing has been driven forward for economic reasons, although this is associated with correspondingly long delivery times from suppliers. Spot orders for fluctuating demand are therefore difficult to implement with overseas suppliers. For this reason, a suitable mix of suppliers (regional and national) was selected for each product group in order to be able to cover such “quick fixes”

Add to this the occasional extreme consumption by customers, and the balancing act between the required guaranteed availability and the desired economical warehousing becomes even more exciting – especially for purchasers and dispatchers!

If you assume that each buyer has to plan around 4,000 items and is expected to keep delivery readiness as high as possible and capital commitment as low as possible, you understand the dilemma.

Unfortunately, there are other factors that make the tightrope sway a little more, because the disposition of such a large number of items has its pitfalls:

- the poor quality of the demand forecast,

- poor master data quality, which is almost impossible to manage manually.

Scheduling often has too little time for too many tasks

This resulted in incorrect order proposals from the ERP system, which the dispatchers then had to correct manually.

Therefore, an adapted (differentiated) setting of the MRP master data was required, which is essential for the success of a comprehensive MRP strategy.

However, it had to be taken into account that the batch sizes/order quantities are also dependent on the process costs per order and should also be set depending on the value/consumption behavior of the article.

But how is a dispatcher supposed to make this adjustment regularly with 4,000 articles and still find time for strategic tasks?

Holistic approach brings calm to the tightrope act

It quickly became clear that a holistic inventory management system had to be developed and established, as this was the only way to achieve the following milestones on the way to guaranteed availability while keeping inventory costs low:

- Relief for dispatchers in master data maintenance,

- Increase in forecast accuracy,

- Smoothing of fluctuating requirements,

- Support for dispatchers through better data quality,

- Understanding of sales and management board in stock-outs,

- Development of a differentiated disposition strategy,

- Better transparency along the supply chain.

An important component of holistic inventory management is the differentiated disposition strategy, which was developed together with the SCM and inventory management specialists from the management consultancy Abels & Kemmner GmbH.

This was based on the unique selling point of “guaranteed availability”. The clear objective was that even medium and highly fluctuating articles must have a high delivery capacity in the central warehouse. Conversely, this means that availability is strategically more important than inventory costs!

Automatic dispensing parameter maintenance gives the ERP system a helping hand

The central instrument of the new inventory management at HANSA-FLEX was the APS system DISKOVER SCO from SCT GmbH, which served the consultants from Abels & Kemmner as an analysis and optimization tool and was to support the dispatchers at HANSA-FLEX as a “planning engine” in the future.

DISKOVER continuously determines and updates the sales forecasts that are transferred to SAP, using a special algorithm to recognize outlier requirements at an early stage.

DISKOVER also automatically optimizes the scheduling parameters in the SAP system on a daily basis, relieving the schedulers of this task. Using the new planning data, SAP now calculates the purchase requisitions and provides the purchasers with a daily list of items to be procured or rescheduled. The new inventory management system is accompanied by intensive user training.

The interim result is impressive:

Inventories were reduced by € 8 million while maintaining the same delivery capacity and reducing planning costs by 15%.

We are currently continuing to work consistently on the further optimization of parameters and strategies in order to persistently tap further potential, which HANSA-FLEX rightly does not want to miss out on!

[1] Edwin Maringka is Head of Purchasing at HANSA-FLEX AG