Significant differences between SMEs and Industry 4.0

Prof. Dr.-Ing. Gerrit Sames*; Maria Schäfer (BA)

Industry 4.0 – some prefer to call it digitization in business, others the Internet of Things and Services – has become one of the dominant topics in Germany. Unfortunately, however, it is repeatedly stated that German SMEs are not sufficiently engaged with this and that progress in digitalization is too slow. As part of a research project at the Technical University of Central Hesse (THM), the status of Industry 4.0 in SMEs has been examined and evaluated[1]. To this end, 966 companies from an IHK address file were contacted using an online questionnaire. 162 companies took part in the study, which corresponds to a response rate of 17%. The participating companies covered a wide range of different sectors, including mechanical and plant engineering, metal production and processing, tool and mold making, the manufacture of plastic products, suppliers of electronic assemblies and products, and many more. A representative cross-section of industrial companies was thus covered.

In the online questionnaire, the following 6 question complexes with a total of 28 individual questions were investigated. For each question, possible answers were given in different levels of detail:

- Level of awareness of Industry 4.0 and obstacles

- Computing: Cloud and IT systems, object identification

- Supporting business processes through Industry 4.0

- Data communication in production and requirements

- Use of accumulated data in production

- Perspective on Internet technologies and Industry 4.0 and potential need for support

The question arose as to whether significant differences could be found in the initial situation of the companies that took part in the study. This question has been addressed by means of a typology.

A typology is a “methodological tool with which real phenomena are organized and made manageable by expressing what is considered essential[2].” Each type is a representative of a variety of phenomena that share some common characteristics. The answers to the following 10 key questions on the status of Industry 4.0 were condensed into types in a cluster analysis (the questions correspond to variables in the cluster analysis):

- How many people are employed in your company?

- Which IT systems does the company use (e.g. ERP, CIM components, BDE, MES, etc.)?

- What options are used in the company to process customer orders?

- Which information carriers are used on components? (e.g. barcodes, transponders, DotCode,…)

- To what extent is external machine communication permitted?

- What options are there for evaluating machine data?

- How are decisions made in the event of a malfunction?

- What communication possibilities exist between the machine and the workpiece in the production process?

- Which of the following information technologies are used in manufacturing? (from sensor technology to CPS)

- What role will Internet 4.0 (Internet of Things and Services-IoTS) play for the company in the next 5-10 years?

To interpret the typology, all 10 variables of the cluster analysis were taken into account. Furthermore, it was checked whether other variables from the questionnaire could provide additional impulses. This analysis led to the inclusion of the variables on the level of awareness of Industry 4.0 and the area of activity. The remaining variables could not be included as they had no distinguishing features with regard to the types.

As a result of the cluster analysis, a total of 5 types can be identified[3], which exhibit different attitudes and technological advances with regard to Industry 4.0. They can be characterized as foxes, beavers, hares, marmots and hedgehogs. While the “foxes” are to a certain extent pioneers of Industry 4.0, the “hedgehogs” show no interest in Industry 4.0 and can be described as very conservative. Table 1 shows the percentage distribution of companies by type.

Table 1: Percentage breakdown

| Cluster/Type | In percent |

| Foxes | 9 |

| Beaver | 20 |

| Rabbits | 31 |

| Marmots | 7 |

| Hedgehog | 34 |

| Total | 100 |

The “Foxes” type has the highest level of technology and serves as a role model for the other types, as individual elements of Industry 4.0 are already being actively and consciously implemented. There are also the “beavers”. They state that they only know about Industry 4.0 from the media, do not deal with this topic proactively or plan to implement it in their company, but they are unconsciously using Industry 4.0 technologies. The third type are the “hares”. These companies use some technologies, but they are still cautious when it comes to Industry 4.0. They are aware of the potential future role, but do not yet see the need to act immediately. The “marmot” type is very similar to the “hare” type. However, the technological level of the “marmots” is lower because they have not yet responded to increasing digitalization in terms of communication options and the IT connection of the machines. The fifth type is the “hedgehog”. They characterize a group of companies that do not attach great importance to Industry 4.0, but instead stick to their conventional methods and techniques. They have the lowest level of technology of the entire typology, but represent the largest group.

In the following, only the two types with the greatest differences are briefly presented: foxes and hedgehogs.

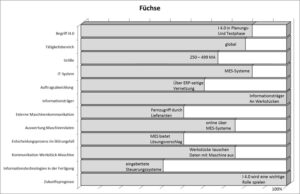

The foxes

The “foxes” represent the highest level of Industry 4.0 technologies (Fig. 1). In their prominent position, they are the ones who show the other types or companies how the path of digitalization towards Industry 4.0 works. These are very large SMEs that operate globally and are using Industry 4.0 in the planning or test phase or are even already implementing it in individual projects. Industry 4.0 will play an important role for them in the coming years. They are also aware that there is no way around Industry 4.0 in the future. The automation of production and order processing is well advanced. Orders are processed with the most important customers via an ERP-side data network. Individual components are already equipped with information carriers so that data can be exchanged between the workpiece and the machine and communication within the value chain is possible. As soon as faults occur in production, the MES system used or the control station set up offers suggested solutions to eliminate the fault as quickly as possible. Machine faults are rectified remotely by the suppliers. For example, small interventions on machines can also be carried out from abroad. Embedded systems are used in the production process to monitor and control it. The “foxes” can serve as trailblazers for other companies. They show how Industry 4.0 can be implemented and can therefore serve as motivators and models for many companies.

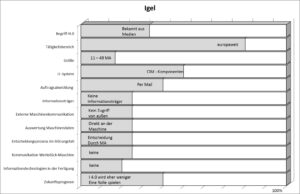

The hedgehogs

Although the group of “hedgehogs” (Fig. 2) is aware of Industry 4.0, they do not attach much importance to it. In her opinion, it will play a less important role in the coming years. They are satisfied with their production structures and do not attach any importance to change. These are micro-enterprises with predominantly few employees, but which are active throughout Europe and globally. They are not aware of the changes that digitization will bring and the impact this will have on the international market and competition. The predominant use of CIM components is striking, although their potential is not being exploited. There is neither a network between machines nor a direct network between machines and computer systems, so that data can only ever be evaluated at the machine and malfunctions in production can only be rectified by an employee. They must develop proposed solutions independently and without the help of an IT system, and decide how to deal with the problem. Companies are a long way from automating production.

The manufacturers of plastic products are largely evenly distributed between the “beaver”, “rabbit”, “marmot” and “hedgehog” types. It is striking that not a single plastics production company appears in the “foxes” category. Companies in mechanical and plant engineering as well as metal production and processing dominate the “hedgehog” type.

Due to these very different starting situations for the various Industry 4.0 types, it can be assumed that the implementation of Industry 4.0 will also differ. This means that different implementation concepts are required. A research project currently underway at the Technical University of Central Hesse is working on the task of developing suitable implementation concepts for the 5 types on the way to Industry 4.0. The first results are expected in 2018.

Bibliography

Sames, G.; Ostertag, W.: Study Industry 4.0: Where do SMEs stand? http://www.ebusiness-lotse-mittelhessen.de/40-ebusinessthemen/182-industrie-4-0wo-steht-der-mittelstand

Schäfer, M. (2016): Development of a typology based on an empirical study on Industry 4.0 in SMEs; BA thesis Technische Hochschule Mittelhessen

http://wirtschaftslexikon.gabler.de/Archiv/10607/typologie-v9.html

[1] cf. Sames, Ostertag (2016)

[2] Gabler Business Dictionary

[3] cf. Schäfer (2016)

*Gerrit Sames is Professor of General Engineering. Business administration, in particular organization with a focus on ERP systems at the THM Business School in Gießen and partner of Abels & Kemmner. He previously held management and board positions at the Monier Group, Schott AG and Buderus Heiztechnik GmbH.