Since Logocos has been using DISKOVER to create its sales forecast, the processes have become more reliable and efficient. One factor was particularly decisive.

By Denis Pradel, Head of Production Control at Logocos and Armin Klüttgen

Logocos has replaced the Excel-based and therefore error-prone forecasting based on the gut feeling of the sales staff with artificial intelligence (AI)-supported sales forecasts based on the Advanced Planning & Scheduling System DISKOVER from SCT, the introduction of which was supported by the management consultancy Abels & Kemmner. Today, in daily exchange with the ERP system Infor-LN, it supplies all the necessary gross planning requirements that the company needs for its operational scheduling decisions. The result: better data and increased transparency with a significant reduction in workload as well as numerous additional benefits thanks to the automatic reporting system, which is also popular with other areas of the company such as marketing and controlling.

Logocos Naturkosmetik, which has been part of the L’Oréal Group since the end of 2018, has been committed to natural care for the whole family based on ecological principles for more than 40 years. The products of the SANTE, LOGONA, Heliotrop, Ihre Klassiker and FITNE brands are characterized by natural ingredients, environmentally friendly packaging and demonstrably environmentally friendly production. Genetically modified or radioactively irradiated raw materials and packaging materials are expressly avoided, as are raw materials containing mineral oil or synthetic dyes. Instead, we use pure vegetable oils as well as active ingredients and raw materials from controlled organic cultivation and wild harvesting. Such vegan natural cosmetics are all the rage, but are also a challenge to produce as their shelf life is limited. The most accurate possible sales forecasts for individual product batches are therefore necessary, as stocks, which are always needed as a buffer for fluctuating demand, quickly become unsaleable. It is therefore also necessary to reduce the buffers at the end of the shelf life in as controlled a manner as possible and with as little loss of sales price as possible.

Forecast horizon of up to 18 months

In the past, calculations and forecasts were therefore always made with the utmost care and great effort. Each sales employee had to consider how much each item would be sold to each customer in the future. The forecast horizon of 6 months has a direct impact on operational planning decisions. However, forecasts must also be made up to 18 months in advance. This time horizon is required in order to conclude strategic framework agreements with suppliers on future delivery volumes. The available quantities of the raw materials used are limited. They are also sometimes subject to certain harvest cycles. That is why you have to conclude long-term contracts. In the long term, therefore, we want to know as precisely as possible which products are likely to be purchased. Ideally, you don’t have to reorder, but have contractually secured the required quantities.

Personal assessments are not resilient in highly complex situations

With such long planning horizons, personal assessments, experience and also the mentality of the sales employee naturally play a role – cautious sales employees make different forecasts than optimistic ones. The large number of products also makes it difficult for sales staff to make an assessment: Logocos currently lists over 2,800 end products. Each individual item had to be planned for each customer. However, if a tab was forgotten to be pressed in the Excel forecasting tool previously used, the quantity was suddenly only a thousandth of what was actually required. It was therefore always foreseeable that, despite all the care taken by every employee, a minor or even major error would always occur at some point given the wealth of data to be planned. This is because there are also very different order quantities per item, which is why incorrect order quantities cannot be identified for a plausibility check using outlier analyses alone.

The larger the table, the greater the number of errors

As a result, working with Excel sometimes led to serious errors, which is certainly due to the complexity of the task, for which spreadsheet programs like Excel are simply not made. Operationally, these forecasting inaccuracies led to increased costs and hectic production processes and, in some cases, overpriced material purchases. This was the case, for example, when a large customer order from a drugstore chain could no longer wait, but the stock in the finished goods warehouse was no longer sufficient for the required batch. Logocos was therefore keen to find a way to further optimize its sales planning.

Automatic sales forecast replaces manual work

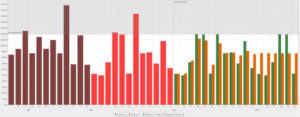

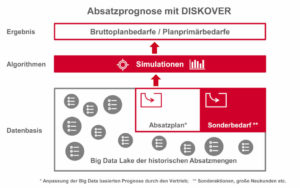

Operationally, the gross planned requirements/planned independent requirements are now calculated automatically on a daily basis in an Advanced Planning & Scheduling (APS) system and fed back to the ERP system – in this case Infor-LN – for the downstream operational procurement process. The ERP system now provides the actual sales figures on a daily basis, while the APS system in turn calculates the forecasts based on this data plus the forecasts based on sophisticated, AI-based simulations and algorithms. The gross planned requirements/planned independent requirements determined in this way are transferred back to the ERP system. Previously, sales forecasts were only entered manually into the ERP system once a month. If the proposed forecast data from the APS system is automatically presented to the sales department today, the employees can decide for themselves whether they want to check all the data in detail or whether they want to rely on the forecasts determined using quasi knowledge-based artificial intelligence. The APS tool used, for example, uses distribution-free methods that deliver more precise results even with non-normally distributed demand. It automatically recognizes seasonality and trends, automatically adjusts historical time series if necessary and includes a regression analysis to analyze and compensate for atypical sales fluctuations. It automatically determines forecast values and required safety stocks in context and not retrospectively on-top. However, it also offers a set of rules with transparent parameters that can be set individually for each customer and which the sales department can and should help to adjust and which should also be checked from time to time. Finally, only the atypical deviations need to be analyzed and the corresponding adjustments made, which are then taken into account in the sales forecast calculation and daily data transfer to the ERP system.

Special cases still under control

The special highlight and decisive factor:

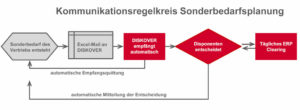

In addition, each sales employee can also individually register special requirements – for new products, customers, listings and special promotions – in the APS system on a purely forward-looking basis. This additional function is also used intensively at Logocos. The requirements are reported using a standardized Excel spreadsheet, which the sales department sends to the APS system by e-mail. This automatically evaluates the table received. The dispatcher has the data sovereignty to activate these forecasts. Receipt by the APS tool and the arming of the data is automatically acknowledged to the sales employee. This results in a closed and transparent control loop. Once the special requirements have been activated in the APS system, they are transferred directly to the ERP system in the daily clearing run. The APS system therefore initially makes a standard sales forecast based on historical data and monthly simulation. This is optionally adjusted by the sales department on the basis of plausible change requests for order quantities per customer. In addition, the sales department can continue to actively and very easily control all other special requirements on top itself – but always on the basis of reliable data. This is how the final sales plan is created.

“If customers use APS software, they differentiate between sales forecasting and sales planning. Sales forecasting is upstream of planning and attempts to identify actual market demand on the basis of knowledge-based rules and regulations. Sales planning represents the final plan as a commitment by the sales department. The DISKOVER APS system used at Logocos therefore consistently distinguishes between the objective recognition of market demand and the subjective planning of the sales department in sales forecasting and planning. How the two planning processes are then passed on to the ERP system Infor-LN as gross planned requirements/primary planned requirements can be controlled by Logocos as required,” explains Armin Klüttgen, Principal of the management consultancy Abels & Kemmner, who supported the introduction of the APS software.

Clear set of rules promotes transparency in sales forecasts

As a result, the forecast is no longer based on a sales staff member’s estimate, but on the completely transparent rules of the APS system, which also knows the underlying historical order quantities of the individual customers for each item. This knowledge-based AI system can therefore be used to decide individually for each article-customer constellation how the forecast should be handled before it is transferred to the ERP system as final sales planning. With so many different articles and customers, there are always special cases that need to be assessed individually. For the first time, such assessments can now be made very transparently and comprehensibly at any time.

Extremely convenient reporting function

Specific, automatically generated reports also make it possible to have the deviations detected via the daily calculations and monthly simulations checked in push mode, or to have parameter settings regularly checked and acknowledged so that, for example, exceptions do not become standard. Product management can also be automatically provided with all relevant information for discontinued products. For example, you can have expensive minimum stocks checked every few months. The flexibly configurable report dispatch triggers can also be used to automatically send overdue orders to the purchasing department. Once all this has been set up, evaluation and dispatch are completely effortless. This makes work much easier for everyone involved.

Other departments also benefit

It used to be extremely time-consuming to compile such lists by hand. Now a report is only generated once and can then always be sent automatically according to a customizable set of rules. Today, the APS tool even provides valuable insights for Logocos marketing. Logocos provides reach analyses from the APS tool so that regional marketing measures can be checked against real forecasts. “Since the DISKOVER APS system already has many standard reports and you can quickly modify them, you can also quickly get usable results that no longer have to be regularly reworked in other tools to adapt them to your own needs – that’s perfect,” explains Sabine Rabing, clerk in the order center at Logocos. Management and controlling can also benefit from the use of this APS tool, as many key figures such as stock turnover or average stock are already part of the tool’s standard repertoire and the forecasts can also be used to plan with dynamic sales prices, for example, so that valuable foundations can also be provided for any budget planning scenarios.

Introduction revealed data errors in the ERP system

As part of the introduction of the on-premise APS tool, Logocos also experienced how important master data and parameter settings are. During the launch, Logocos took the opportunity to tidy up the entire article master and correct errors, which is of course essential for a clean forecast. Many errors were uncovered simply due to the high transparency requirements of the APS tool. The alert system automatically reports deviations, such as delivery times that are twice as long, which may only have been caused by a typing error in the ERP system.

Intuitive and easy to use without much training

“In daily operation, the APS tool is intuitive and there is a lot of information at a glance in the individual screens. It is very self-explanatory. Just a short training session and then you can get started, because everything is simply very logical,” explains Dennis Pradel, Head of Production Control at Logocos. Some of the terminology in the ERP system Infor-LN is different to that used in the APS tool DISKOVER. “But once you’ve dealt with these differences, it’s no longer a problem.” The graphical representation is also clear. DISKOVER does not provide a typical ERP mask with bare rows of figures, but automatically generated diagrams that make it easy to read a forecast.

At least one working day saved per month and sales employee

The time and effort required for monthly sales forecast planning has been significantly reduced since the introduction of automatic sales forecasting. Previously, almost every sales employee spent around 2 days a month on planning, creating 20 files and around 12 different reports. Today, only special campaigns have to be planned manually and deviations analyzed; however, these are processed in a standardized way and everything is much more transparent than before. Receipt slips are sent by the APS system for each special plan requirement. “This high level of transparency of the APS system ensures that nothing gets lost. In a way, this is both a blessing and a curse,” explains Pradel. “Ultimately, however, this transparency also helps people to deal with the important things and not look for errors in Excel tables and extinguish trouble spots in production.”

Root cause analysis with just a few clicks

Fluctuations in sales forecasts are now much easier to understand. “Even if goods become too much or too scarce, you can get the essential information you need very quickly,” adds Rabing. “The question is: has something gone wrong in production or is it due to a change in demand? If the latter is the case, you can communicate directly with the sales staff and get to the bottom of the matter even more precisely in order to then initiate appropriate measures.” The high level of transparency ultimately helps to make an ever better overall forecast for an increasingly efficient supply chain and more efficient production. Thanks to the high level of data transparency, it is now possible to avoid unnecessarily expensive retooling in production caused by incorrectly estimated sales or Excel errors. The improved forecasts have ultimately also led to greater calm in production.

Data quality convinces even critical sales staff

“The longer we work with it, the more satisfied we are with it,” summarizes Pradel. “Initially, the sales department had reservations about the quality of the forecasts.” It’s hard to let go of your gut feeling. It needs trust. For this reason, the data was initially compared with the previous planning methods, but it quickly became clear that the automatically generated sales forecasts were comparable and only showed deviations of around 5-10% – which can always be cushioned with suitable safety stocks. Sales therefore became increasingly satisfied. They have got rid of the XXL Excel tables for the standard forecasts, and since special requirements for critical customers can be predefined and automatically applied using a set of rules, the forecast is always set appropriately based on the rules. Anything that is inconspicuous no longer needs to be looked at today. You only have to focus on the deviations, which ultimately leaves more time for the essentials: Acquiring new customers and looking after existing ones.

Possible ERP/APS constellations

Different constellations can be selected for the interface between ERP and APS systems, and the rules for which system is responsible for which task vary accordingly. For example, an APS system can be used exclusively for sales forecasting, as is the case at Logocos. Without this special function of the APS system, it can also optimize scheduling based purely on the order data from the ERP system. The expansion levels of the APS system’s responsibilities to deliver optimized data to the ERP system range from the delivery of gross planned requirements/planned independent requirements to planned orders, production orders and purchase orders. In this expansion stage, APS systems are used directly as operational systems and replace this functionality of the ERP system. Logocos currently uses the APS system to supply data to Infor-LN, which is broken down into weekly gross planned requirements/planned independent requirements using the planned value distribution method. Logocos therefore still has the option of converting the scheduling itself to the APS system in a further step. The reasons for this often lie in reducing inventory while at least maintaining or even increasing delivery readiness through the optimized use of forecasting processes and extended rules and regulations, which classic ERP systems do not offer. Another reason may also be the more intuitive and efficient user guidance, in order to further reduce purely operational-administrative tasks and thus create more time for qualitative tasks.