By Dirk Etgeton and Michael Lingen[1], ikado GmbH

Many companies have different purchasing systems with complex data structures that need to be decoded in order to purchase direct materials successfully and sustainably.

It is not uncommon for many plants in a group of companies to purchase the same components and materials independently from a large number of suppliers.

But how can synergies, commonalities and optimized purchasing be ensured?

Typical problems that occur when analyzing purchasing-relevant data:

- several plants buy the same parts from the same supplier and do not know it

- the same goods are purchased via distributors, often from different ones the same goods are managed by different plants under different material numbers

- the same component is purchased in different plants from the same supplier but at different prices, currencies and conditions

- There are important components that are only purchased from one supplier.

- the origin and supply chains of the components and materials are not known

Creating more transparency – but how?

Uncovering, repairing and linking such data inconsistencies and intransparencies is a laborious task for which there is unfortunately all too often not enough time in practice. It is easier if you have the right tools to analyze the large amount of information and data in a targeted manner.

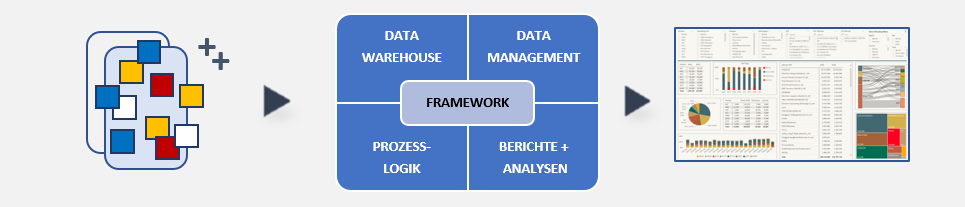

To do this, we use an analysis platform that has been developed over many years, is sustainable and can be expanded at will, allowing us to cut through the Gordian knot of data. We usually proceed in four steps.

- Inventory

The first step is to develop an understanding of the data, the processes and systems, the corporate structure, the business environment and the company’s goals.

Because “you can only improve what you know” – quote from an old hand from the purchasing management department of an automotive supplier.

- One-off detailed analysis of the data

If these potentials are promising, the next step is to analyze the data in detail. It usually takes a few weeks to evaluate the data for direct and indirect purchasing material taken over by the company. The time is needed to clean up, consolidate, categorize and prepare historical and future purchasing data.

- Development and design of analysis tools

If the knowledge gained is to be safeguarded for the future, a one-off clean-up is not enough. A further project step, in which the consultants work intensively with the client’s project team, serves to establish sustainable processes, tools and roadmaps for achieving the objectives in purchasing.

- Realization and implementation

In a final step, the findings from the previous project steps are implemented. This means, among other things

- Adaptation of purchasing and negotiation strategies / purchasing and

- Company objectives in accordance with the analyses performed previously

- Identification of further savings opportunities

- Creation of key figures for purchasing

- Price variance analyses

- Supply chain transparency

- Analysis of delivery and payment terms

- Introduction of metrics for data quality

Documentation

At the end, the new purchasing processes are documented and handed over to the company to ensure that the knowledge gained and processes developed are still understood even if the original project team members are no longer available after some time due to staff turnover.

The methodology presented here has proven itself in numerous projects and typically leads to the following in purchasing organizations

- Negotiating (with data and facts) at eye level with suppliers

- Reduction of material costs

- Improved liquidity in payment transactions

- More time for value-adding activities

- More transparency and efficiency in company processes

- Management on the basis of key figures

- Improved decision-making for purchasing decisions

Once again, this shows the hidden potential that lies in improving data quality and systematically processing unstructured data in many companies.

[1 ] Michael Lingen is Managing Director and Dirk Etgeton Head of Consulting at ikado GmbH, Aachen, an IT systems and consulting company that specializes in data optimization in purchasing, among other things.

Featured image: Thrive Themes