What is possible today at the technological forefront of supply chain optimization, what the efficient optimization of logistics and supply chain management has to do with the crash test of car bodies and why a digital twin helps to optimize your logistics business model.

We are all familiar with the drastic images of crash tests from pictures and videos in which the bodywork bends alarmingly around an obstacle.

In the past, countless crash tests were necessary during body development in order to achieve the right torsional rigidity of a body on the one hand and plasticity on the other. This took a long time, was very expensive and still meant a residual risk for the later operation of the car, as it was not possible to optimize every last detail. The optimization of car bodies has been taking place in the computer for some time now. The body parts are assembled using simulation software and subjected to countless crash tests. Test cycles can be carried out much faster, you can optimize more precisely and thus eliminate the residual risk more reliably.

Empirical simulation for a better overview of the supply chain

What is standard in car body development represents the technological pinnacle in the optimization of processes in supply chain management and logistics. Empirical simulation is the only way to bring improvements out of the fog of gut feeling and into the sunshine of objective facts. The interplay of value streams, requirements, forecasts and scheduling decisions in a company and throughout the entire supply chain is so complex that it can no longer be penetrated with common sense and years of experience alone.

Many practitioners know from daily experience how volatile the entire logistics business model is, with its value streams, decoupling points, storage levels and planning and control processes:

- There is not enough supply capability despite high stocks;

- Scheduling results are person-dependent and change with every staff turnover, vacation or sickness replacement;

- Improvement processes are slow, laborious and yet not sustainable;

- Priorities change regularly because no one has an overview of the interplay of processes.

An empirical simulation of the dynamic behavior of the entire supply chain in the computer makes it possible to check the effects of different solution approaches in advance and without risk and to arrive at objective numerical values. This makes discussions more objective, a consensus can be reached more quickly and decisions can be made more quickly and easily. While classic optimization of logistics processes involves slow, careful and laborious progress in pilot phases and tests with a small number of items, logistics business models that have been simulated in advance can be implemented quickly.

Digital twin depicts processes and flows

Logistical optimization using simulation is not rocket science. It all starts with a so-called digital twin of the value streams and planning and control processes. This digital twin can be generated from the deep ocean of data in an ERP or merchandise management system by combining article master data, historical time series of customer orders, purchase orders and stock issues, parts lists and, if necessary, the data from the ERP system. work plans and other data as required. Whereas in classic value stream design it can take weeks to map a value stream for selected representative articles, a complex logistical value stream model covering all material numbers is available within a few days.

And while classic value stream design only works with static average values, the digital model takes into account the dynamic behavior of the materials in the value stream. This not only makes the results more detailed and differentiated, but in many cases makes them realistic and reliable in the first place. Static average considerations, on the other hand, all too often fail in the dynamics of practice.

In order to simulate logistical effects with a digital twin, the changes to be analyzed are made to the model and simulated over a defined period of time in the past – typically 12 months. The simulation results can then be compared with the practical results known for the past and thus evaluated.

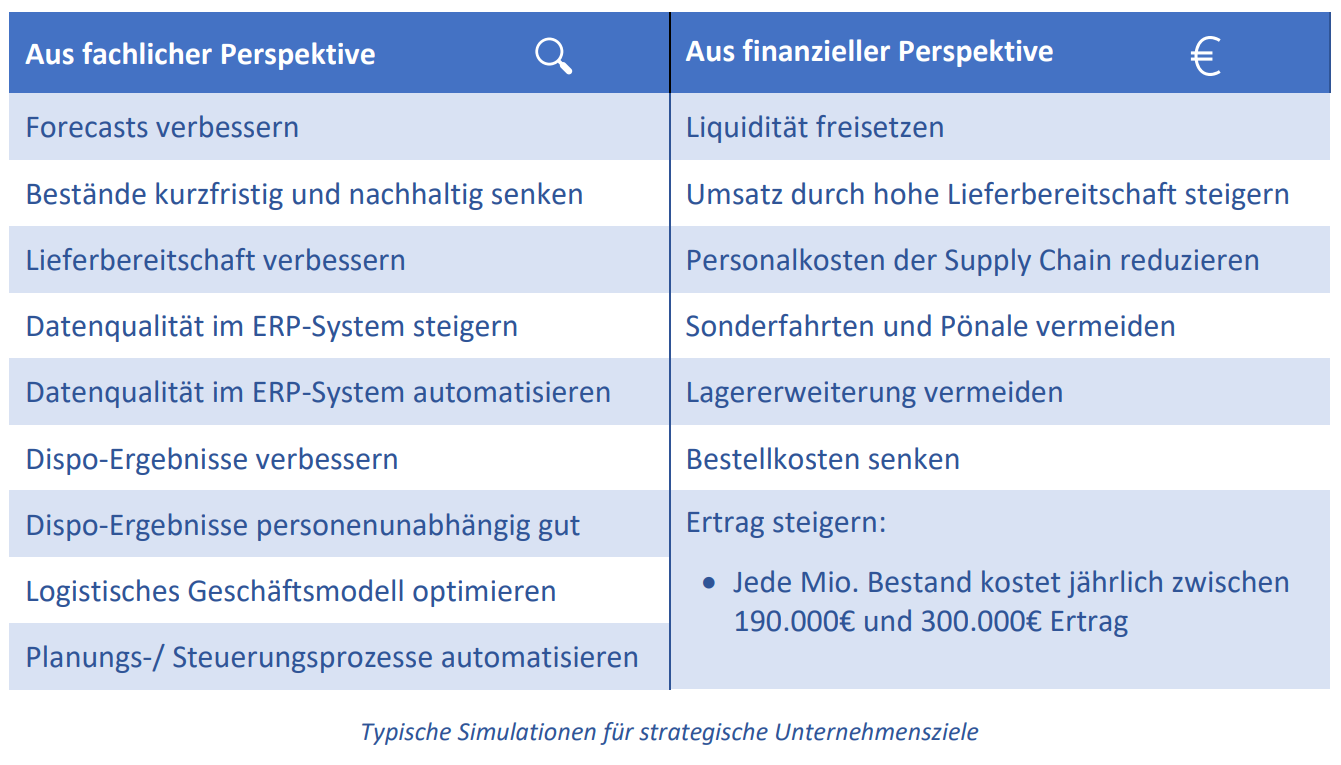

Simulation helps with strategy, forecasting and optimization

The simulation approach is very broadly applicable. It can answer strategic questions, such as the optimization of the logistics business model or the restructuring of value streams. He can take care of improving sales forecasts or scheduling, balancing stocks and delivery readiness or answering detailed questions.

The questions can relate to individual, selected or all articles and can concern the entire value chain, even across several company levels. They can relate to selected segments of the value chain or just to a single storage stage.

A few specific examples from different sectors may help to illustrate the situation:

At the lingerie manufacturer Anita Dr. Helbig, A&K used the simulation approach years ago to demonstrate that the planned reduction in throughput times would have little impact on inventories throughout the global supply chain. Improving the sales forecast was identified as a decisive lever. This measure enabled the stock to be reduced rapidly.

Trost, today a brand of WM SE, one of the leading automotive parts wholesalers in the independent aftermarket in Germany and Europe, pursued the goal of largely fully automated replenishment of the approximately 150 stores. Using simulation, A&K simulated the store’s replenishment strategies down to every single relevant planning and replenishment parameter for each item and developed a set of rules for setting the replenishment parameters. This has now been in operation for several years and has sustainably reduced inventories by a high double-digit million amount.

Fritz Driescher KG, a medium-sized manufacturer of medium-voltage switchgear, was pursuing the goal of significantly reducing current stocks and establishing a more efficient value chain. Using a dynamic empirical simulation of the entire value chain, A&K developed a new logistics business model in which the logistical decoupling points were shifted, an 80/20 leveling system combined with a Kanban system was set up, personnel capacity management was introduced and a scheduling rule set was implemented to tune the ERP system. As a result, it was possible to drastically reduce current stocks and significantly increase the efficiency of the entire value chain. Without the simulation of the solution concept in advance, the development of the new logistics business model and its implementation would have required significantly more time and effort.

As one of the leading DIY suppliers in Germany, GAH Alberts needs to be able to deliver at the highest level. By simulating the planning processes, A&K developed a combination of short-term and sustainable measures and implemented them as an MRP control system, which reduced inventories by 53% within nine months.

In cooperation with the Swiss Sihl Group, the decisive starting points for improving the consistency of the international planning chain were identified and jointly implemented by means of a logistical simulation of the value chain

A&K is currently working together with a major international manufacturer of technical components on a new concept for the logistics business model with the aim of reducing inventories by a high double-digit million figure.

Understanding the real process anew with the digital image

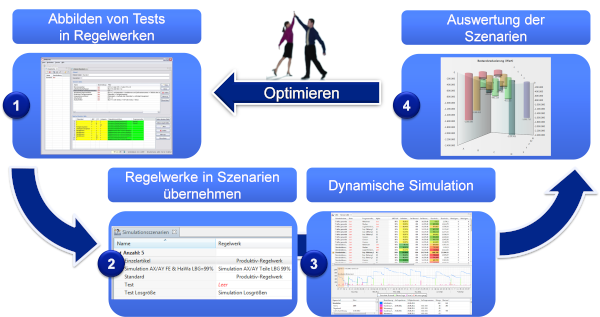

By and large, logistical optimization is performed by empirical simulation in several iteration loops. Solution approaches are defined by the project team, mapped in the system and simulated. The results are analyzed and the solution approach is iteratively optimized. A powerful simulation system can perform some of the optimization tasks automatically. using artificial intelligence mechanisms, by independently determining the solution that best achieves a given optimization goal from a given range of possible solutions.

The preceding explanations sound a lot like theoretical work on a computer. However, such a digital twin does not spare its users an understanding of the logistical conditions and restrictions in the company. While some of the potential for improvement can already be identified through various tests and simulations on the digital twin, many potentials only arise from knowledge of the company situation and the current handling of processes in the company; logistical simulation therefore also requires experienced experts.

A simulation project therefore begins with a down-to-earth process analysis and consists of regular workshops in which optimization approaches are jointly identified and reviewed with the company’s employees. It results in an action plan with fields of action and sub-projects.

It is therefore worth looking into digital rather than conventional optimization methods. The advantages are obvious. Practical application has shown that the simulation approach is usually more cost-effective and more profitable than conventional optimization methods. The larger the item portfolio under consideration, the greater the cost advantage, as the number of material numbers to be considered has practically no effect on the project costs. In addition, the simulation approach enables shorter payback periods than traditional optimization projects thanks to the faster implementation of the solutions developed. From this alone, a typical logistics simulation project practically finances itself.

Picture: Honda_CT_Simulation_Animation