Optimal batch size: Economic batch sizing methods – how do they work?

For the optimum batch size, let’s take a look at economic batch sizing methods. Economical lot-sizing processes for reducing the overall costs of warehousing and procurement or set-up costs offer a large, mostly untapped potential for reducing costs. In order to apply economic lot-sizing methods correctly, users must understand the principles and limitations of economic lot-sizing methods.

Ziele der wirtschaftlichen Losgrößenverfahren bei der Losgrößenoptimierung

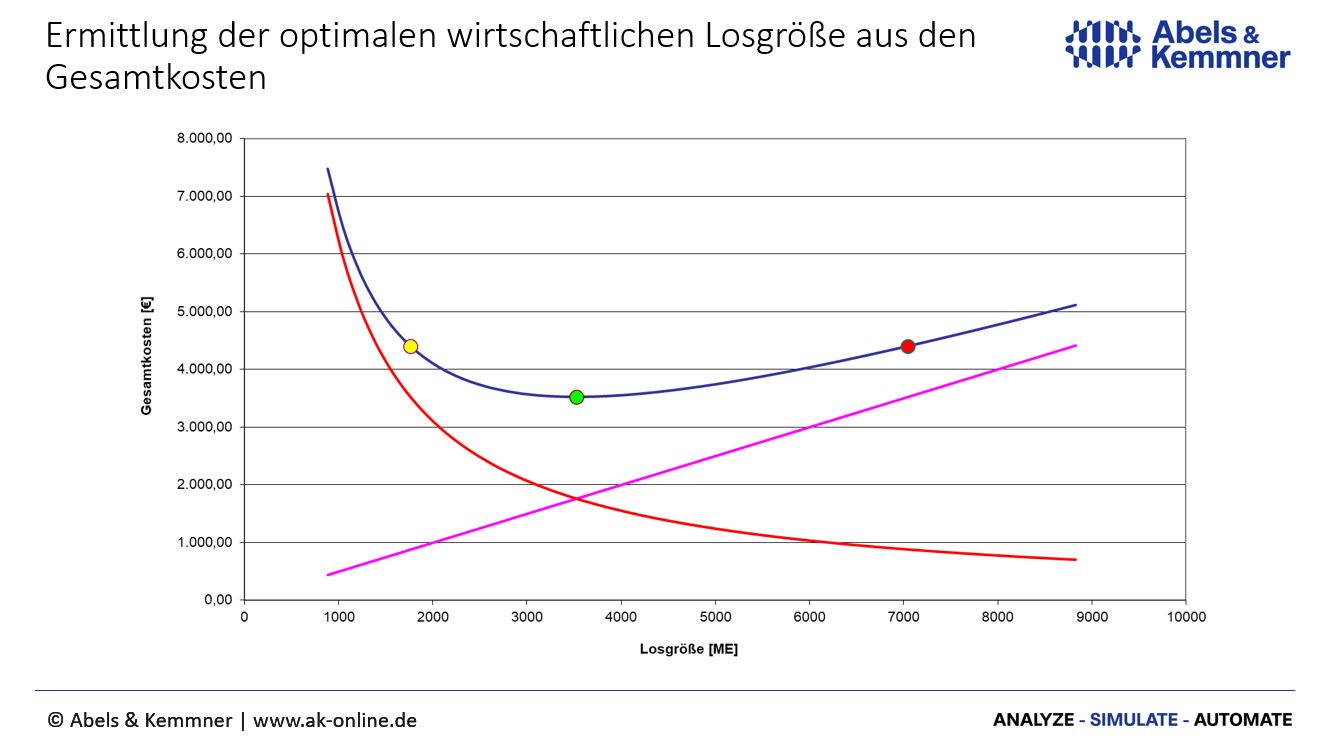

Economic lot-sizing methods aim to minimize the total costs for an item under consideration, consisting of inventory costs on the one hand and procurement costs for purchased items or setup costs for in-house production items on the other. This optimizes a small, essential component within the entire supply chain that is often overlooked in practice.

Larger batch sizes in procurement or production lead to higher inventories and therefore higher warehousing costs. These generally increase in proportion to the batch size, while the ordering costs or set-up costs – generally referred to as batch run costs – decrease in inverse proportion. A simple example: If the same absolute transportation costs are incurred for a part for batch size x as for batch size 2x, then each part only bears half of the transportation costs if twice as many parts are ordered.

If certain costs rise in proportion to the lot size and others fall inversely in proportion to the lot size, then there must be a minimum total cost for a given lot size (see Fig. 1).

Die klassischen wirtschaftlichen Losgrößenverfahren

One of the first to recognize the connection between inventory costs and batch circulation costs was Kurt Andler . In 1929, he developed a formula for calculating an economic batch size. The Andler formula is still widely used today. When calculating the optimum batch size, Andler assumed that the total quantity required for an item in a planning horizon, e.g. one year, is known. The formula now derives the batch size that should always be used for ordering from inventory costs on the one hand and procurement costs on the other. As the lot size remains constant over the planning period, this is also referred to as a static economic lot-sizing method.

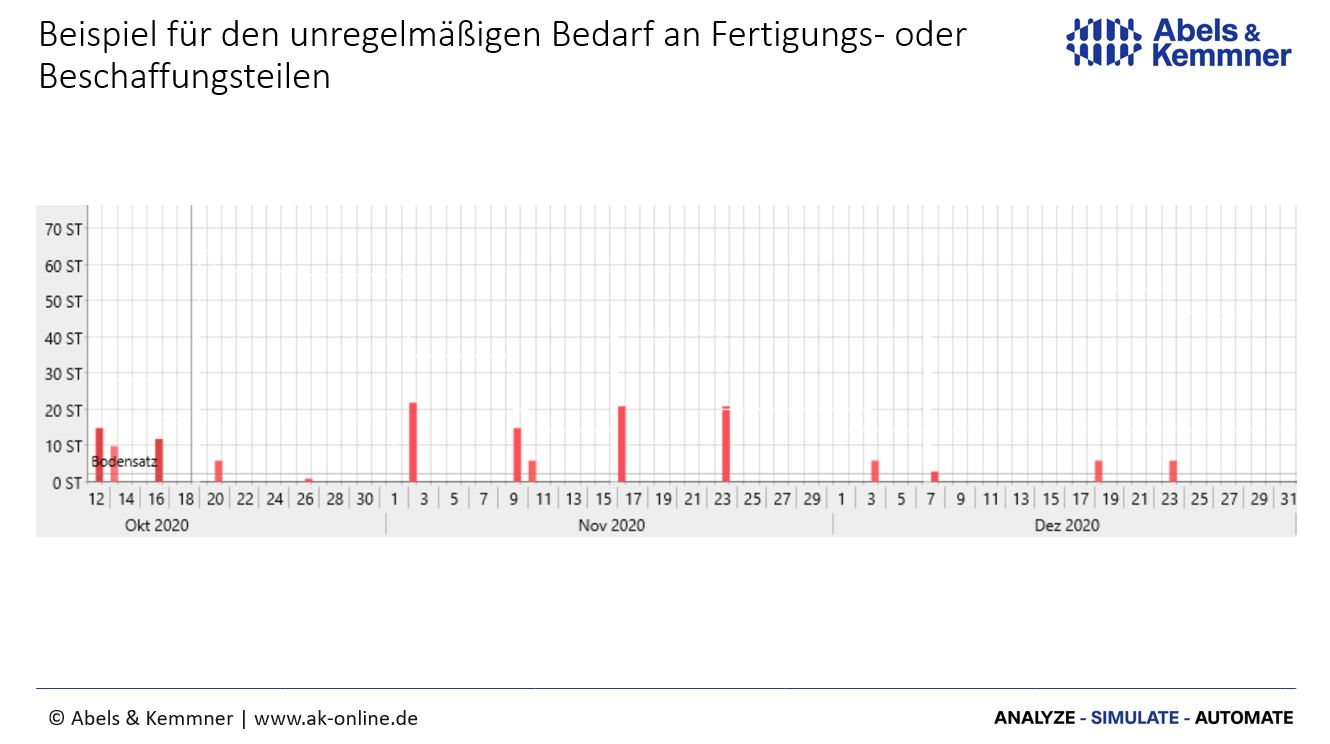

In practice, however, production or order requirements are rarely evenly distributed over the planning horizon. Rather, they follow each other irregularly and are of different heights (Fig. 2). The decisive answer as to how to determine economic batch sizes for “dynamic” requirements was provided by two Americans back in 1958. Messrs. Wagner and Whitin developed an economic lot-sizing method with which dynamic lot sizes could be calculated. This mathematical solution takes into account the fact that the decision on a first lot size in the planning horizon automatically limits the scope for the design of subsequent lot sizes. The Wagner-Whitin method determines a sequence of lots with different sizes and different time intervals, which minimizes the total costs. The result is a scientifically precise answer to the question of the correct batch sizes for single-stage, single-product production without capacity limits.

The Wagner-Whitin method was too complex to be used by hand or with the calculating machines of the time. In the course of the following years, approximation methods were developed which, at the expense of theoretical accuracy, manage with little computational and storage effort. In 1968, for example, the part period method and the sliding economic lot size method, and in 1973 the Silver-Meal method and in 1979 the Groff method were introduced. These are the “classic” economic lot-sizing procedures that are offered in many ERP systems. In addition, there are a large number of other methods for determining optimum batch sizes that have so far found little resonance in practice.

Herausforderung Verfahrensauswahl – optimale Losgröße und wirtschaftliche Losgrößenverfahren

If economic batch sizes are calculated for the same demand situation for an item using different methods, the calculated batch sizes usually differ significantly from one another. In practice, this leads to major irritations.

However, the question of which economical batch sizing method actually leads to the lowest total costs under real conditions can be answered with modern, powerful software tools.

Read also Optimal batch size – calculate the most cost-effective batch size with economic batch sizing methods

What is your experience of optimum batch sizes and economical batch sizing processes? Write to us!

You can find more helpful tips on our knowledge page.