In recent years, interest in Sales and Operations Planning (S&OP) for demand planning in industry and retail has increased continuously. S&OP is not necessary for every company, as long as three homework tasks have not been completed, no S&OP process should be set up.

The core idea of S&OP is to harmonize the market requirements that a company has to satisfy (demand side) with the possibilities of material supply on the part of procurement and production (supply side) in day-to-day business.

The need for Sales & Operations Planning in demand planning must always be examined if the supply side is unable to provide the material quantities required by the demand side on the required dates over a longer period of time or in principle. However, a lack of material availability alone does not necessarily make it necessary to set up an S&OP process. It may be enough,

- correctly adjust the “logistics business model”,

- improve the quality of automatic demand forecasts,

- correctly set planning and scheduling parameters in the ERP system.

If one or more of these three components are not in order, it makes more sense in terms of material availability and required stocks to do the homework here first before setting up an S&OP process. If these foundations are laid correctly, the supply side may already be able to satisfy market requirements and the expense of installing an S&OP process can be avoided.

A genuine Sales & Operations Planning process in requirements planning always means shortage management

If there are still substantial availability problems after these measures, an S&OP process can help to set the right priorities in order to cause the least amount of sales damage to customers or the market. A true S&OP process always struggles in some way with a lack of one or more resources, primarily material, production capacity, storage capacity or liquidity, which ultimately means that the market cannot be fully served. For sales, this requires decisions as to which customers and products should be prioritized. Depending on the given bottlenecks, these decisions have repercussions primarily on procurement, production, finance or logistics and must therefore be coordinated with these areas. An S&OP process structures the preparation and coordination in terms of timing and content.

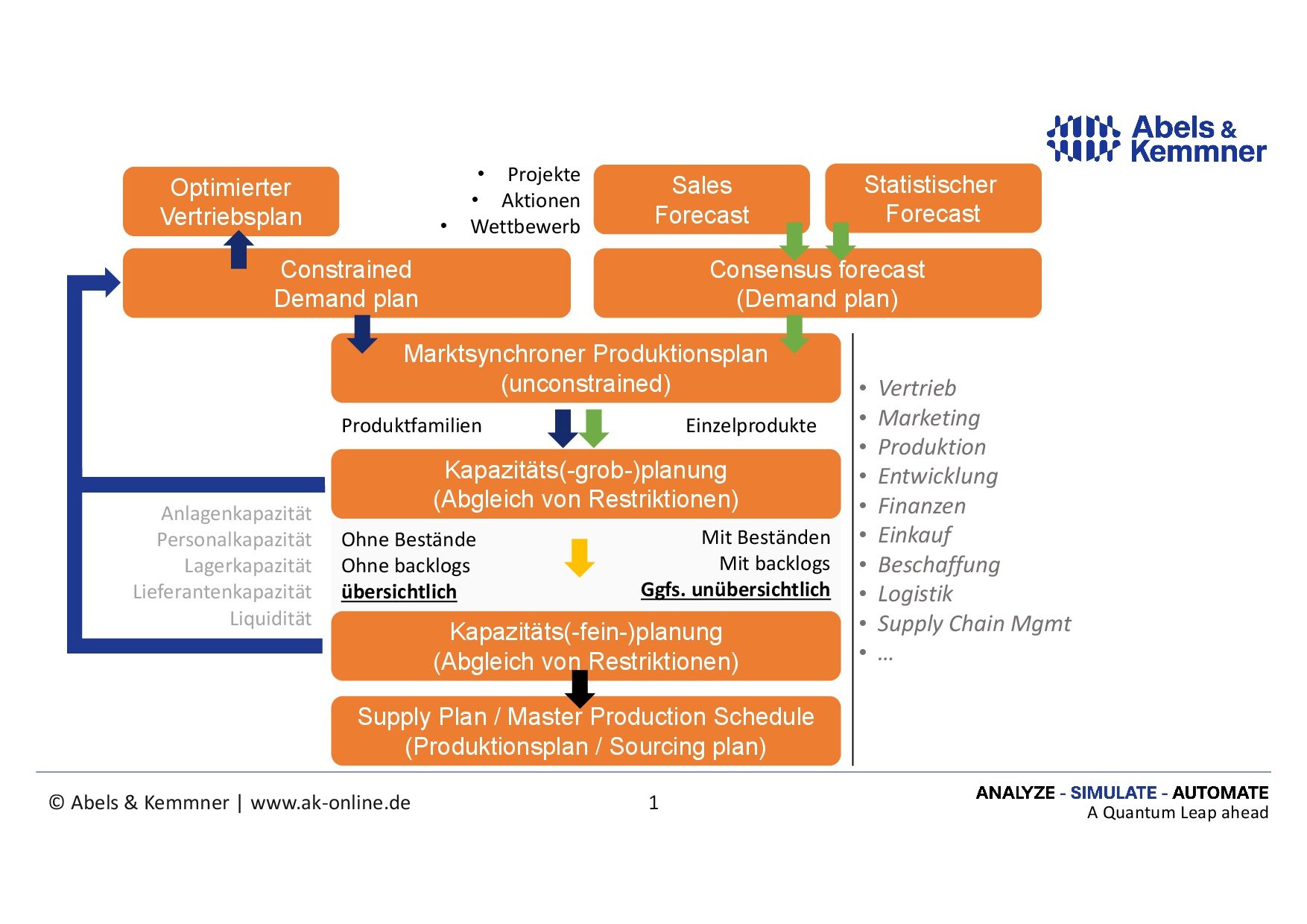

A complete Sales and Operations Planning (S&OP) process for demand planning includes the following tasks, which should be carried out on a monthly basis if possible:

Determine market requirements

The future market requirements are determined as precisely as possible

Feasibility check

It is checked whether production and procurement are able to fulfill the expected market largely on time and in the right quantities. For this purpose, the entire market requirements (unconstrained forecast) are planned “against unlimited capacity”. The result shows a possible lack of resources, particularly a lack of storage capacity, a lack of production capacity, a lack of personnel, insufficient material supply from suppliers or a lack of liquidity.- Resource expansion or reconciliation If the required resources can be expanded economically or are sufficient after all by bringing forward procurement and production quantities, the reconciliation process is already complete here.

- Prioritization of requirementsIfit becomes apparent that the resource bottlenecks cannot be sufficiently expanded to satisfy all anticipated market requirements, priorities must be set within or between customers, sales channels or sales companies, or all must be quoted equally. This coordination initially concerns the various sales areas. However, the inclusion of procurement and production may become necessary if compromises are found on the sales side that have consequences for the supply side.

- Adoption of the final requirements planThejointly agreed requirements plan must then be made available for further planning processes in procurement and production. For an S&OP process to be successful, it is important that all parties involved, demand side and supply side, adhere to the agreements made.

The challenge of considering resources

The feasibility check raises the question of how detailed the resource comparison should be. This question is particularly important when considering capacity bottlenecks. If capacity planning is carried out on the basis of individual capacities and detailed work schedules, a very detailed picture is obtained of the capacities that are still lacking despite possible adjustments. However, the result is so detailed that it is difficult to recognize the necessary correct consequences; you can no longer see the wood for the trees, so to speak.

Alternatively, the congestion situation can also be viewed in condensed form. The focus is then on bottleneck capacities, critical work processes and usually only considers product or product groups. However, it is then no longer possible to compare this with existing stocks and back orders can only be roughly taken into account at best. You are then in a world of gross planning.

Does a Sales & Operations Planning process offer any flexibility at all in demand planning?

A jointly agreed requirements plan that is updated and fixed on a monthly basis – that doesn’t exactly sound like agile production. An S&OP process brings peace of mind to procurement and production plans by avoiding ongoing rescheduling. This increases efficiency at the expense of short-term flexibility. However, the flexibility that short-term rescheduling supposedly allows hardly leads to any improvements in a bottleneck situation, as only one problem can be solved by causing another problem. A characteristic feature of bottlenecks is a lack of flexibility.

Some companies try to allow a small degree of flexibility by not planning a certain proportion of material stock or production capacity. However, this approach means that some customer or market requirements that can still be realized are not served in order to be able to meet spontaneous customer requirements. From a sales perspective, this can make perfect sense if it enables new customers to be acquired without losing existing customers and the bottleneck situation is only temporary, so that existing customers can be served again in the short to medium term.