In today’s world of turbulent flows of goods, different methods of supply chain optimization are required than in the old world of steady flows of goods.

Panta rhei-everything flows – even in the supply chain. Static calculations and static solutions therefore fall short! Empirical simulations in the digital twin help.

Since we have left the age of largely variant-free mass production behind us, static considerations have fallen short when designing supply chains. For a long time, perhaps until the coronavirus crisis, demand and goods for Renner products flowed more or less evenly. These 20 to 30 percent of the entire product portfolio often account for 60 to 80 percent of the total turnover, the total capacity utilization and often also the procurement volume. The steady flow of goods from these masses often masked the already turbulent flow of goods and demand for the rest of the product portfolio. Many companies therefore thought they could cope with static average considerations, as used in classic value stream design.

Turbulent flows of goods and demand defy static considerations

In the meantime, however, the world has changed. Today, we are also experiencing turbulent demand and turbulent flows of goods when it comes to fast-selling items. Erratic demand behavior, unreliable replenishment, unreliable production capacities, unreliable transport routes… Conventional static considerations from the old uniform world do not produce useful results when it comes to the design of value streams and the necessary planning and control mechanisms.

Such static considerations, such as average inventories, average consumptions, average idle times or average capacity utilization, are typically used in value stream mapping and can even lead to dangerous, wrong decisions.

Classic value stream design can also lead to incorrect concepts if only representative articles or article groups are considered. Ultimately, there can be no “one fits all” solution for a heterogeneous product portfolio, as is the case with most retail and production companies. Different article behavior requires different planning and scheduling mechanisms and usually also different value streams. Implementing such differentiated strategies is no longer a problem in modern supply chain management.

However, the challenges in today’s world of turbulent supply chains go even further. There are no more static solutions. Value streams must be adapted to constantly changing demand behavior, as must planning, control and scheduling parameters. The half-life of defined decoupling points, storage levels, replenishment times or dispensing parameters is getting shorter and shorter.

Dynamic simulations in the digital twin better reflect reality

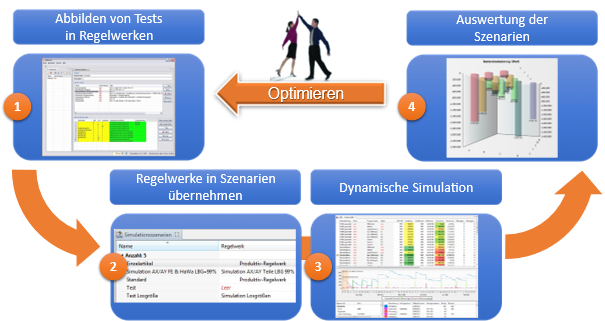

These challenges can be overcome by dynamically simulating the value streams and value stream behavior in a digital twin of the value chain or supply chain. The simulation of different strategies and solutions is based on real empirical data. We use the DISKOVER tool for this purpose. The resulting solutions no longer represent fixed values, but are mapped in sets of rules and, where these fall short, are readjusted in regular simulations.

The optimization of supply chain management in the digital twin on the basis of empirical data verifies concepts developed under real conditions and enables their rapid implementation

The optimization of supply chain management in the digital twin on the basis of empirical data verifies concepts developed under real conditions and enables their rapid implementation

That sounds complicated, and it is! But a car is also complicated and yet we get on well with it because the technology is under the surface. This is also the case with modern tools for supply chain optimization.