We live in a data- and algorithm-driven business world. Data and algorithms also play a key role in the planning and management of value chains in companies and global supply chains. Work on improving the algorithms has been ongoing for many years; the functionality of supply chain management software, from ERP systems to specialized APS systems, has been continuously refined.

However, the quality of the data used by the algorithms has not kept pace in many companies. This applies both to the input data that is processed by a software function and to the control data that regulates the behavior of the software functions themselves.

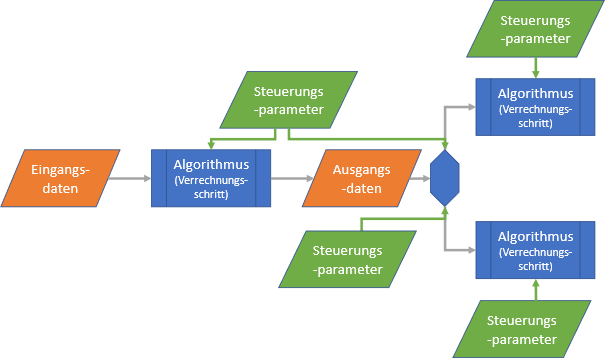

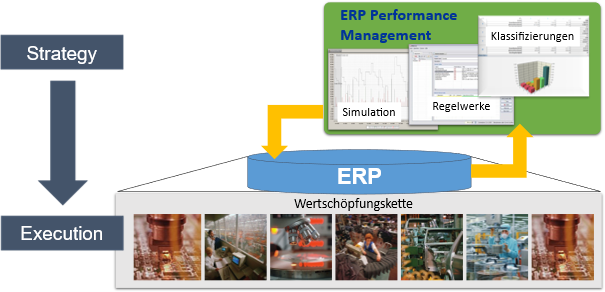

Fig. 1Every software system ultimately consists of a sequence of algorithms that process input data and are influenced by control parameters in terms of their content and sequence.

Fig. 1Every software system ultimately consists of a sequence of algorithms that process input data and are influenced by control parameters in terms of their content and sequence.

Particularly critical in this context is the data that describes the sequence of calculation steps in an ERP system.1-The functions control the behavior of a functionality itself. Although this data is not only data that is used in the scheduling algorithms, but also data that controls the behavior of the entire planning process, in technical jargon it is generally referred to as disposition parameters or MRP parameters.

Nothing works without correct scheduling parameters

Without “correctly” set MRP parameters, an ERP system will not generate any useful forecast values or sensible MRP suggestions, forcing users to make their own considerations about future material requirements and sensible replenishment. Instead of using the expensively paid-for functionality of the ERP system, companies are thrown back on the gut feeling of their dispatchers and the ERP system is only used as a golden typewriter.

Stable planning and scheduling processes that achieve identical results under the same boundary conditions cannot be achieved in this way. The fact that scheduling decisions are dependent on people and chance and change with every vacation or sick leave replacement is a daily occurrence in countless companies. A sustainable, economical value chain, in which the desired delivery readiness is continuously maintained with the lowest possible stock levels, is also a long way off with manual processes.

Fewer errors in the planning and control processes, faster processes and differentiated processes can only be achieved with more process automation, for which good dispensing parameters are of decisive importance.

Up-to-date, complete and error-free scheduling parameters are also of strategic importance for the future productivity of our companies. A large proportion of today’s personnel costs in our companies are incurred in administrative areas and no longer on the store floor. Urgently needed increases in productivity can therefore only be achieved by rationalizing and automating administrative areas, including demand planning, operational procurement and production control.

Ultimately, demographic trends will force us to automate more in the coming years, as the personnel required for these supply chain management tasks will become increasingly difficult to find and increasingly expensive to pay.

Conventional maintenance of disposition parameters does not lead to success

In discussions with companies, the responsibility for poor scheduling parameters is usually seen as lying with the users: “Unfortunately, our people don’t maintain their scheduling parameters in a disciplined manner,” they say. However, a simple calculation shows that manual master data maintenance would take far too much time and is therefore unrealistic.

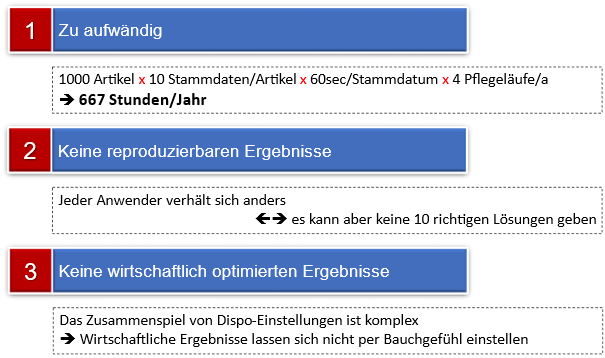

Fig. 2Conventional maintenance of disposition parameters does not lead to success

It is important to understand that all items are subject to a life cycle and that market demand is influenced by many factors. It is therefore not sufficient to set the MRP parameters of an article once when creating the article. They must be readjusted regularly. If a user is responsible for 1000 material numbers, has to maintain 10 dispensing parameters for each material number, spends an average of 60 seconds per dispensing parameter for calling up, thinking about and setting parameters and has to check the dispensing parameters four times a year, this would take 667 hours per year. This corresponds to an additional 40% job per planner, dispatcher or production controller just to maintain the MRP parameters! In practice, planners are usually responsible for far more articles, have to maintain more than 10 parameters and, if possible, do so monthly and not just once a quarter.

It could be argued that the staff would have the time to maintain the scheduling parameters, as better scheduling parameters would enable greater automation. However, if every user maintained their own master data, neither reproducible scheduling decisions nor stable scheduling processes would be possible. Every user behaves slightly differently, has different experiences and a different perception of risk and therefore adjusts the dispensing parameters differently from their colleagues. Can there be 10 different correct solutions for one disposition decision? Probably not!

It makes more sense to define standardized criteria for all users as to how dispensing parameters must be set. In the 1990s, therefore, the idea of the scheduling manual emerged, in which, among other things, specifications were made for the maintenance of scheduling parameters. These dispatch manuals were not widely successful; we now only very rarely find corresponding work instructions. The scheduling manuals initially failed due to their manual application, which meant that the time required to maintain the scheduling settings was more time-consuming than with individual data maintenance based on the user’s gut feeling. However, even where this hurdle has been overcome with appropriate software support, the results of scheduling have not been satisfactory.

The biggest hurdle in maintaining scheduling parameters is that the dynamic interplay of requirements, forecasts, scheduling decisions and value streams in the company and throughout the entire supply chain is so complex that it cannot be penetrated with common sense alone.

It is therefore not enough to standardize setting rules and automate their application. The first step is to set all the relevant scheduling parameters for each individual material number, which are interlinked in many algorithms, in such a way that they lead to economical scheduling decisions on average, not in individual cases (!), given the dynamic operational processes. Different companies may well pursue different objectives. Should the required readiness for delivery of an item be achieved with the lowest possible average stocks or with the lowest possible costs, or is the focus on reducing inventory and ordering costs? It can also make sense to pursue different profitability targets for different items within a company.

Economic settings for scheduling parameters can only be found using simulation

In order to find the right settings for scheduling parameters under the dynamic circumstances described above, in our experience there is no economic way around simulations with empirical data. The only alternative to this approach would be to make parameter settings in practice using trial-and-error a lengthy, complex and risky undertaking.

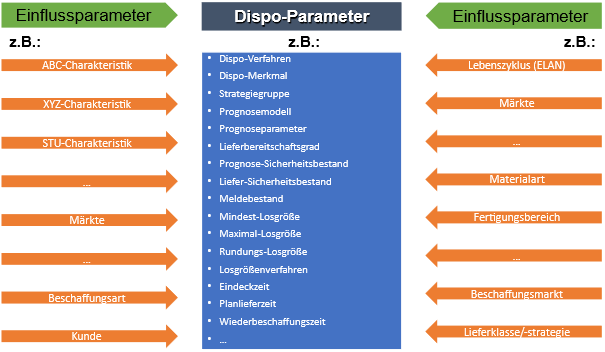

Fig. 3Disposition parameters must be correctly set and adjusted depending on numerous influencing variables

We draw on the extensive historical databases of the ERP system to optimize the dispensing parameters using simulation. By linking customer order histories, stock issue histories and stock flows with article master data, parts lists, routings and other ERP data, a complete dynamic model of the structure and value stream behavior of an entire supply chain can be created. This digital twin of the physical supply chain conceals the special features of market behavior as well as the special features of value stream behavior. This digital twin can be used to empirically determine and improve the effects of different MRP parameter settings on stock levels, readiness to deliver, warehousing and ordering costs, the number of incoming and outgoing goods and other cost drivers so that the desired economic goals are achieved as well as possible.

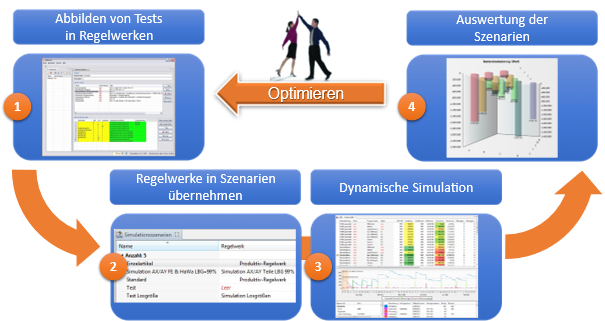

Fig. 4: In a digital twin, the most economically sensible settings of the scheduling parameters can be determined systematically and empirically.

The strategy and operational behavior of supply chain management is encoded in rules

If you were to simulate all the options for setting the scheduling parameters for every single one of a company’s countless articles, this would be impossible to manage with the current performance of our computer systems, and if it were possible, the result would be completely confusing. Experience shows that this effort is not necessary if you proceed more skillfully. Instead of attaching the dispensing parameter settings to a material number, you determine under which boundary conditions, with which classification features of articles and with which article properties which parameter settings deliver the best economic results. Rules can be derived from this which state that “If an article belongs to this article class under these boundary conditions and has the following properties, then this MRP parameter is assigned this setting value.” In this way, rules can be structured into decision tables and successive decision tables into sets of rules.

These sets of rules contain the complete control intelligence of operational planning as well as the strategic considerations for the strategic positioning of your own supply chain. In this context, we speak of mapping the logistics business model in rules.

If these sets of rules are mapped in a suitable software system, such as DISKOVER, they enable the continuous and automatic maintenance of scheduling parameters. As DISKOVER can not only maintain the scheduling parameters but also carry out the simulations, the most sensible alternative settings for key scheduling parameters can be determined automatically for each individual item by means of empirical simulation and applied directly instead of coding them into rules.

The result is extensive CNC control of the ERP machine

DISKOVER automatically maintains the scheduling parameters of the ERP system without users having to intervene and spend time. As the care process does not require any effort, it is carried out daily. In this way, the parameter settings are readjusted promptly and the number of changes per maintenance run is kept to a minimum.

Fig. 5A powerful system for maintaining scheduling parameters is as important for an ERP system as CNC control is for a machine tool.

Of course, the future will not consist of fully automated planning processes. Planners and dispatchers are still needed. However, we must use this valuable human resource where human intervention is essential and human experience is indispensable. Today, a large part of our employees’ intelligence is wasted on tasks and articles that could be handled independently by well-maintained planning and scheduling algorithms. As a result, other tasks that urgently need to be tackled by employees are falling by the wayside.

So let’s turn the management of our supply chains upside down and redistribute the responsibilities between algorithms and humans in the right way.