Admittedly, it is a harsh statement to say that everyone is helping the climate but planning. However, it is closer to reality than the claims made by some providers of APS or planning systems, which give the impression that their specific planning algorithms make a significant contribution to reducing CO

2

-emissions (their carbon footprint).

Most companies today are trying to reduce their CO

2

–footprint; if not out of conviction, then at least for marketing reasons. Every department is called upon to make its contribution. Understandably, system providers of APS and planning systems are also trying to show that they can help their customers to reduce CO2-emissions. If you follow the publications of the system providers, pretty much every system function is cited across the board as contributing to CO2 reduction. Concrete figures are practically never found.

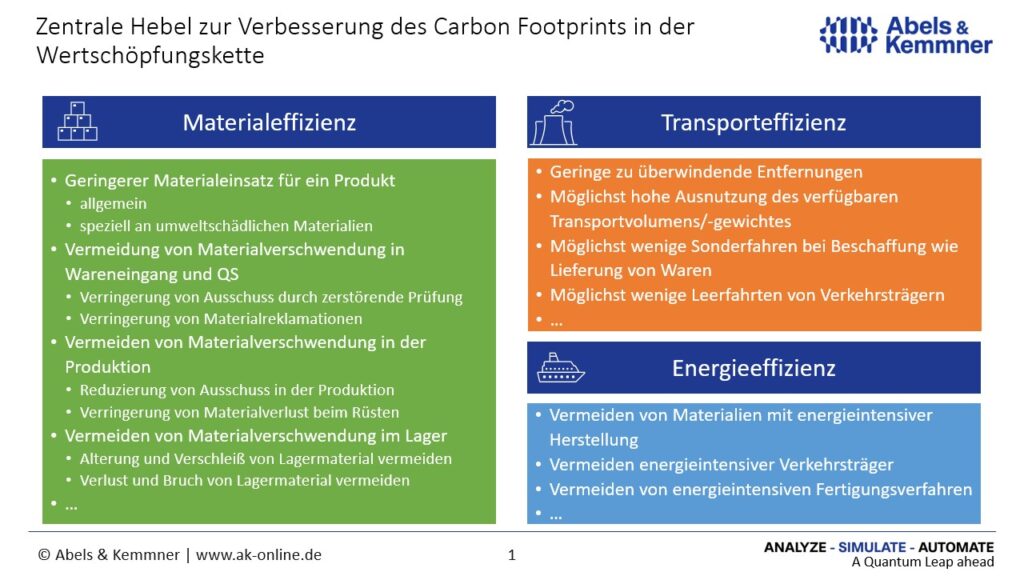

Three real levers for reducing the carbon footprint

To reduce the carbon footprint and harmful environmental impacts of a value chain, there are three main levers that cannot always be clearly separated from one another:

- Material efficiency

- Transport efficiency

- Energy efficiency

APS or planning systems can only contribute to reducing a company’s CO2 consumption to the extent that they act on these levers.

To what extent do planning systems really help to operate these three levers?

A detailed analysis quickly reveals that many planning and scheduling measures cannot influence material, transport and energy efficiency. Where planning and scheduling exert an influence, the effects are sometimes in opposite directions and in some cases success depends on external conditions that are difficult to influence.

For example, higher stock levels can lead to improved delivery readiness and therefore fewer special trips (higher transport efficiency). On the other hand, higher stocks can lead to more ageing, wear, loss and breakage (lower material efficiency).

Suppliers in the vicinity may increase transport efficiency. However, if the closer supplier procures its goods from further afield, the world has gained nothing; the company has merely done some clever accounting.

So do planning and scheduling do nothing to reduce the carbon footprint?

contribute?

However, if it is possible to achieve the same delivery readiness with less stock, every one percent reduction in stock saves 55 to 90 per mil of CO2-reduction. That doesn’t sound like much, but it adds up to 1.1% to 1.8% if you achieve a 20% reduction in stock. How we arrive at this value is explained in another blog post.

At present, however, many companies are hoarding stocks without being able to maintain their previous delivery readiness, as some incoming materials are still missing and goods cannot be produced and delivered on time. Planning and scheduling decisions therefore currently do nothing to improve the carbon footprint in most companies, but rather worsen it. Other priorities are currently at the forefront for many companies and modern, more efficient APS or planning systems can make a more significant contribution to these priorities than to CO2-reduction.