Specific analysis:

Data-based & data-driven

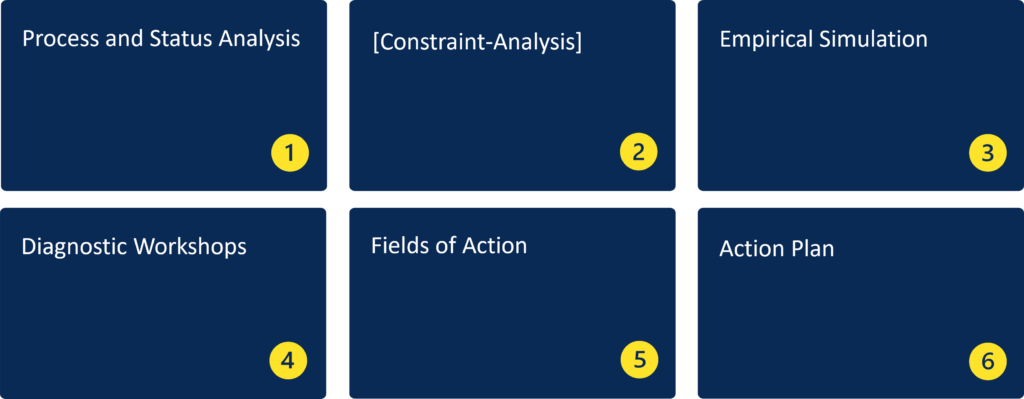

Our situation analysis methodology is specifically designed to optimize the overall concept of your supply chain. We start with a thorough process and status analysis to ensure that your processes are recorded precisely. At the same time, we transfer master and transaction data from your ERP system and, if necessary other sources, and verify and cleanse the data. This data forms the basis for analyses and simulations of improvement approaches in the digital twin. In complex cases, we also develop detailed cause-and-effect networks as part of a constraint analysis in order to uncover potential for improvement from a second perspective. All findings are incorporated into the definition of fields of action and the detailed specification of improvement measures.

Empirical simulation

in the digital twin

The core competence of our approach is empirical simulation: we use the data from your ERP system to create a digital twin of your supply chain network. In this safe, virtual environment, we run “what if” scenarios to simulate potential changes and their effects without disrupting the operational system. These simulations are a powerful tool for identifying optimisation potential.

Diagnosis & development of measures

Through diagnostic workshops, we work with your team to identify quick wins and derive specific areas for action. The result is a tailor-made action plan that not only identifies optimisation approaches, but also includes a detailed cost estimate and a realistic implementation plan. The entire process is designed to be completed within a timeframe of 4-6 months so that you can benefit from the improvements quickly and effectively.