Reorganization of the supply chain process at Montegrappa, Italian manufacturer of exclusive writing instruments

By Gabriele Racinelli and Benjamin Grell (project members at Montegrappa) Dr. Bernd Reineke and Andreas Capellmann

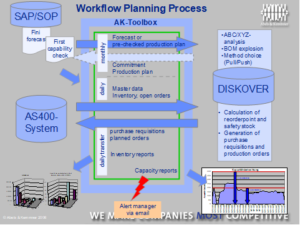

Montegrappa is a traditional manufacturer of luxury writing instruments based in Bassano del Grappa, Italy. In recent years, artisanal production has been increasingly confronted with new requirements due to current market developments. A high level of planning security and the optimal utilization of available resources are essential in the new market environment. The DISKOVER optimization and planning tool has made it possible to automate the planning and control process and thus significantly accelerate it.

The previous planning process was only rudimentarily supported by the outdated ERP system. In addition to the necessary transparency, there was a lack of basic functionalities such as requirements planning, BOM explosion or capacity planning. The process was supported more poorly than well by numerous individual solutions based on Excel and handwritten documentation.

The planning process was correspondingly lengthy and time-consuming, not to mention the many potential sources of error that led to major uncertainties. Furthermore, the effort for planning and controlling production was to be reduced by switching to pull mechanisms for the procurement of regularly required parts, which was not supported by the existing ERP system. In order to speed up the planning process and increase planning accuracy, it was decided to introduce a suitable planning tool as a subsystem of the ERP system. Daily routine tasks in production planning and material procurement were to be automated and accelerated by the tool. The choice fell on the DISKOVER planning and optimization system from Abels & Kemmner GmbH.

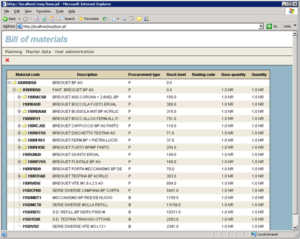

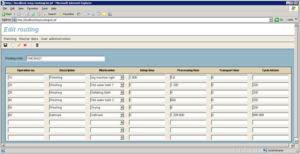

In addition to the functions for forecasting and planning the supply chain as well as end-to-end scheduling with graphical processing of the planning results, DISKOVER impressed with its new MRP (Manufacturing Resources Planning) functionality. This includes primary and secondary requirements planning with BOM explosion, capacity planning and scheduling based on routing data.

DISKOVER SCO – The second generation

of the successful disposition management tool from Abels & Kemmner

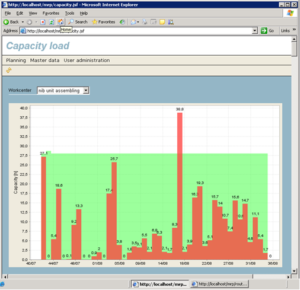

The new scheduling management add-on for ERP systems, DISKOVER SCO, is optionally accessible from any workstation with a web browser thanks to web server-supporting technologies, without the need to install special software. Thanks to the graphical evaluation of capacities, bottlenecks in machines and personnel can be quickly identified. No time is lost in reacting to the situation.

Data procurement and processing proved to be a major challenge for the project. On the one hand, the ERP system, which runs on an IBM AS/400 machine, had to be connected without manual intervention by the planner. Secondly, a range of data had to be compiled and documented: Work schedules, calendar and machine capacity data as well as personnel capacities. In the course of the project, further master data had to be revised that was available in the ERP system but had never been used due to the previous procedure and was of poor quality. These included replenishment times, batch sizes and minimum order quantities. Orders and customer orders also had to be checked and revised, as there were many “data corpses” in the system that led to incorrect results.

The DISKOVER system was implemented on the basis of an MS-SQL database on a server directly in Bassano. The IT team at the parent company Richmont developed interface programs that read the necessary data from the ERP database in Milan and write it to transfer tables in the MS SQL database. Within a short time, these programs were running very stably. DISKOVER has been set up so that the data transfer is triggered as soon as the interface data is available and the MRP run then starts. This made it possible to synchronize both systems without losing time and without manual intervention and to keep them at the same data status.

In addition to the technical solution, the focus was on integrating and qualifying employees. Thanks to the direct involvement in the project and the participation of the planners in the conception and decisions, those involved were always up to date and were able to familiarize themselves with the system. Additional user requirements could thus also be incorporated and realized in the implementation of the system and the interfaces. In addition to minor adjustments to the screen interface, these were additional reports that enabled a condensed presentation of the procurement situation. This included a missing parts overview that not only displays the affected orders and products, but also shows the procurement situation of the missing part and the higher-level material at a glance at the touch of a button.

The direct display of capacity requirements within a freely selectable period made planning even easier. With Montegrappa, the capacity requirements are summarized at weekly level and displayed graphically. A switch in the master data enables automatic capacity balancing, which shifts orders from overload periods to periods with free capacity according to predefined priority rules. This is particularly helpful for bottleneck capacities such as the CNC department for turning and milling the writing instrument bodies. In assembly, the capacity analysis is used to plan personnel resources, possibly with the addition of seasonal or temporary workers.

All in all, it was worth the effort. By using DISKOVER, it has been possible to significantly increase the accuracy and transparency of planning and at the same time drastically reduce the workload. Based on a monthly demand forecast for the finished products and daily updated data from the ERP system, DISKOVER determines all the activities required to fulfill the sales plan. The results are transferred to the ERP system in the form of orders or production orders, which remains the leading system.