Simple, fast and reliable

By Dr. Götz-Andreas Kemmner

Are my stocks too high? By how much could we reduce stocks without jeopardizing delivery readiness? Is it worth bringing in external specialists? These and similar questions come up regularly. How can you answer them quickly? For many years, A&K has been successfully using a self-developed process that makes it possible to estimate inventory reduction potential simply, quickly and reliably on the basis of a small amount of item-specific data.

How can I recognize my inventory reduction potential? John Mullen, Managing Director of Microengineering Ltd.1 in Birmingham, was also faced with this question. Using E:S:A – Excess Stock Assess, the quick analysis developed by A&K to determine excess stock and stock reduction potential, he found a precise answer in no time at all.

If overstocks were so easy to recognize, there would be none!

In order to identify excess stock, the stock reduction potential must be determined on an item-specific basis. However, extensive data is required for these analyses. In addition to master data for all articles, consumption data and demand trends from the past are essential. In order to recognize seasonalities in the demand behavior of the articles, the consumption and demand development data must be determined and evaluated retrospectively over two years. The evaluation itself is a dynamic simulation based on past trends. In this simulation, the behavior of the ERP system is mapped, whereby a series of optimization measures usually take effect that have not yet been used in the ERP system, because otherwise the inventories would presumably be lower than they are today. Such optimization measures relate, for example, to the optimization of procedures and parameters for forecasting requirements and calculating safety stock levels. In addition, a number of special features come into play: for example, the required delivery readiness level is an input variable for the simulation process and not a result variable at the end of the simulation. Article-specific evaluations are therefore essential in order to set up an ERP system correctly. However, they are too time-consuming and therefore too expensive to provide a quick preliminary statement on the overall potential for reducing a warehouse’s inventory and thus provide a plausible cost/benefit calculation for a detailed inventory reduction project.

In addition, a number of special features come into play: for example, the required delivery readiness level is an input variable for the simulation process and not a result variable at the end of the simulation. Article-specific evaluations are therefore essential in order to set up an ERP system correctly. However, they are too time-consuming and therefore too expensive to provide a quick preliminary statement on the overall potential for reducing a warehouse’s inventory and thus provide a plausible cost/benefit calculation for a detailed inventory reduction project.

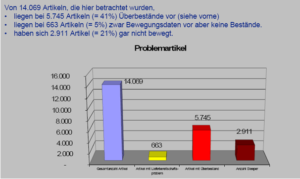

Extract from the E:S:A evaluation

E:S:A – Excess Stock Assess

In contrast to this classic approach, the E:S:A overstock analysis developed by A&K only draws on a range of item-specific master data such as batch sizes and replenishment times, current stocks and item prices, which a company can determine itself with comparatively little effort and send to A&K for a free stock reduction analysis without making internal company information transparent to the outside world.

These and a few other parameters can be used to determine item-specific overstocks and calculate expected stock reduction curves. Summed up over the total number of articles considered, this results in a statement about

- the entire stock reduction potential,

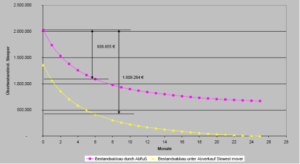

- the expected inventory reduction curve,

- the resulting cost savings and

- the stock level of non-rotating items.

Of course, any type of excess inventory analysis also requires the consideration of safety stocks. The safety stocks serve to cushion the uncertainty about the actual future requirements. Of course, this aspect is also taken into account in the overstock analysis.

The inventory analysis in the E:S:A process represents a snapshot of the situation at the time of data collection. However, as the analysis is carried out across the entire product range, the law of large numbers ensures that this snapshot is also statistically representative of a company’s effective overstock situation. However, it is not possible to make statements about individual articles using this approach. However, they are not necessary at the time when an E:S:A analysis is usually carried out.

The E:S:A procedure is structured in such a way that the company using it does not have to disclose any confidential data if it is prepared to enter the data itself into the free data entry software. Only a compressed set of data is then forwarded to A&K, from which no conclusions can be drawn about individual item data. Only the actual evaluations and processing of the results are then carried out by A&K.

The overstock survey currently being carried out by A&K in conjunction with the technical newspaper “vdi-nachrichten” is based on the E:S:A method.

975,000 stock reduction potential, of which £660,000 can be mined within the first six months, was calculated on the basis of E:S:A for Microengineering Ltd. Reason enough for John Mullen to dig for gold with the specialists from A&K.

1 Names changed for reasons of confidentiality