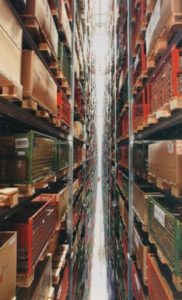

How inventory reduction reduces costs and creates liquidity

If you need a cash injection, you should also take a look at your warehouse. By optimizing the disposition, it may be possible to gain some liquidity.Those who have collateral to offer always get money. Often, however, these securities cannot be provided. In addition, Basel II and Basel III are increasing the requirements for banks’ equity ratios. The higher a credit risk is assessed, the higher the collateral the bank has to provide on its side and the higher the interest rates. This is why the situation for SMEs will not become more relaxed in the near future and, above all, will not become cheaper. This is why the alternative form of financing with the cash injection from the warehouse is so interesting and also virtually free of charge. At the bank, you often pay eight percent or more in comparison.

Many SMEs have not yet recognized this type of financing for themselves. By reducing inventories and working capital, however, liquidity can be created, costs reduced and the ability to deliver guaranteed, if not increased. All of this happens without entrepreneurial restrictions on decision-making authority or returns or both. The advantage of internal financing by reducing working capital is that you remain in control of your own decisions and your own returns. In addition, you even reduce the financing costs for inventories, which are often between 19 and 30 percent.

Companies often have to write off a portion of their inventories, for example because expiration dates have passed or the products can no longer be sold at cost. You have to store what you buy or produce, possibly externally, and you need infrastructure for this. Personnel must also be paid to manage the stock. These and other costs must be added to the financing costs. Inventory assets therefore cost between 19 and 30 percent per year rather than just four to eight percent debt financing.

Sustainability can only be achieved by ensuring that scheduling decisions are made as objectively as possible.

Reducing inventory, on the other hand, lowers costs while increasing liquidity. Stocks must of course be reduced carefully. The trick is to reduce these in such a way that the supply capability can still be maintained, and perhaps even expanded, with the reduced inventories. This can be achieved with suitable approaches in practically every sector, whether trade or production.

Reducing inventories – but how?

As a rule of thumb, it can be said that eight out of ten SMEs can achieve at least a 20 percent reduction in inventory. For a statistically average company in the manufacturing industry, this would enable it to increase cash and cash equivalents by 50 percent or reduce long-term liabilities by 30 percent. The problem for many companies, not just SMEs, is that although they are constantly working to reduce their inventories, the effects are not sustainable. Sustainability can only be achieved by ensuring that scheduling decisions are made as objectively as possible.

Virtually all companies today use enterprise resource planning systems to manage their warehouse, among other things. For very few, however, the system works in a clean, structured way and with the right focus. The errors result from the fact that the systems usually do not map the processes in the company correctly and the employees have to make manual adjustments. Experts often have to make adjustments to find the right operating point and maintain it in the long term.