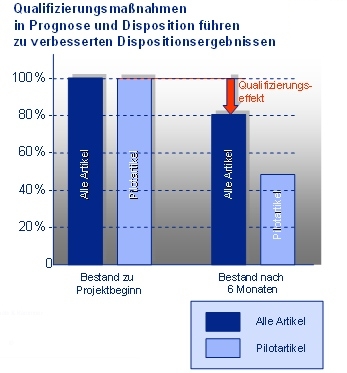

The fact that employees cost money is nothing new. Nor does the fact that qualified, motivated employees cost more at first glance. However, if you take a closer look, good qualifications don’t just mean higher wage costs – they can also bring profits! And not just through smoother, more effective work processes and more motivated employees who can achieve more in less time. In fact, it is possible to prove that professional training measures have a measurable influence on the stock level, particularly in planning and scheduling – and thus quantify it in euros!

Of course, training alone is not enough to sustainably reduce inventories in the long term, optimize delivery readiness and minimize planning costs. But without knowledge of the background, theories and practical application examples, there is a risk that employees will unconsciously fall back into “old patterns” in the medium to long term once a supply chain optimization project has been successfully completed, meaning that some of the problems that were thought to have been eliminated will return.

Planning and scheduling also need practice

In addition to and independently of our supply chain optimization projects, our seminars and training courses therefore teach the theoretical basics of planning and controlling the entire supply chain, from demand forecasting and sales and operations planning, through scheduling and production control to inventory management, logistics strategy and SAP optimization, and combine these training courses with practical application examples on a training system, depending on the customer’s topic and budget.

For example, following our training and practice measures in consulting projects on inventory reduction, we regularly find that the inventory and delivery readiness situation also improves in product areas in which we have not yet changed inventory management: The purchasers and planners apply their new knowledge directly to their entire area of responsibility. And this is precisely the best prerequisite for sustainably lower inventories: recognizing, understanding and implementing.

Not only beginners make mistakes

Of course, you might think that such training measures are all well and good for beginners, but experienced dispatchers don’t need them. But it is precisely this routine that often leads to a certain “operational blindness” that obscures the need to adapt to changing market situations. It is therefore particularly important for the success of a training course that:

- employees and managers are aware of the existing problems,

- The specific problems are addressed and the theoretical background is explained by experts with practical experience,

- apply the acquired knowledge as practically as possible, e.g. on an exercise system, and

- be practiced continuously by the employees.

It is certainly particularly important for the acceptance and implementation of the theories taught and practical application options that training participants have someone in front of them with whom they can discuss and practise “at eye level”. That’s why you should take a close look at where and by whom you have your employees trained. No matter how theoretically sound someone without practical experience may be, your employees will still be able to smell that the teacher has never had to deal with the problems addressed “in real life”. This considerably reduces the likelihood of gaining the aforementioned benefits from the training.

Example of in-house training

But what exactly should a training course look like so that your employees emerge from it with more knowledge and the right tools and, in the worst-case scenario, inventories don’t shoot through the roof again while delivery readiness plummets?

As an example, we show you the structure of a dispatcher training course for ebm-papst Mulfingen GmbH & Co. KG, one of the world’s leading manufacturers of drive and ventilation technology.

The company’s approximately 36 planners and dispatchers were trained in four groups of 9 people. Two training days were scheduled for each group, which were held approximately one to two weeks apart. This resulted in a total of 8 training days. The division into several groups meant that there were no personnel bottlenecks in day-to-day business during the training and also meant that it was possible to work intensively with the individual participants. In order to be able to cover the individual points of the “timetable” in sufficient depth, the two training days were conducted by two consultants per group.

In the overview, the groups were divided as follows:

| Group 1(Day 1 – Kemmner) | Group 2(Day 1 – Kemmner) |

| Group 3(Day 1 – Kemmner) | Group 4(Day 1 – Kemmner) |

| Group 1(Day 2 – Reineke) | Group 2(Day 2 – Reineke) |

| Group 3(Day 2 – Reineke) | Group 4(Day 2 – Reineke) |

The topic plans for each training day show how detailed the individual topics were addressed and what the focus was:

Training day 1:

- Introduction: The importance of production control and scheduling for a company’s success

- Some logistical basics to recap

- Logistics strategists think in item classes

- The chain of effects of inventory and readiness to deliver

- The planning chain in the company links all areas of the company

- The main production control and scheduling processes

- Push and pull

- Disposition mechanisms in detail

- Planned disposition

- Reorder point control

- Special scheduling and production control procedures

- Less hectic production thanks to stable production control mechanisms

- The contradictory goals of production control

- Understanding production with the funnel model

- Logistical positioning

- Understanding the basic laws of production logistics

- More reliable production performance thanks to OEE key figures

- OEE – what is it anyway?

- The OEE calculation in detail

- Evaluation and interpretation of the key figures

Day 1 of the training initially focused on preparing and preparing the theoretical background for the participants. On this basis, the participants were then provided with tips and tricks for their daily work with the SAP ERP system on day 2. For this part of the training, access to the SAP system with certain authorizations was necessary, so that very specific application examples could be taught here.

Training day 2:

- Introduction: Optimization of disposition

- Master data: the unkempt creatures

- Disposition parameters and how they work

- Factors influencing the logistics business model

- Identification of the relevant criteria

- Assessment of the influencing variables and their effects on the dispensing parameters

- Illustration of the mode of action on the exercise system

- Presentation of a case study on parameter optimization

- Procedure

- Concept

- Results

- Short excursion: Forecasts in SAP

- Settings and profiles

- Pitfalls in the application

- Dispatch parameters in the SAP system

- Characteristics of the disposition methods (disposition characteristics)

- Customizing: what to look out for

- Effects of the settings (exercise system, SAP test system)

- Long-term planning as an important planning alternative

- Options for parameter optimization

- Automated parameter maintenance with the dispensing control system

- Introducing simple tools

Short and long-term profit through knowledge

As the ebm-pabst example shows, training is certainly associated with time and personnel expenditure, and therefore of course also costs. But if qualified training for employees, which combines both theoretical knowledge and practical application options, can save just a few percent in inventory, it already pays off.

However, there is often another effect: Based on the acquired knowledge, employees not only tackle daily challenges more efficiently and effectively, but also in a more relaxed and systematic way, and a common technical and conceptual basis is created for internal technical discussions. This is reflected in greater motivation and a better working atmosphere – and that is a long-term gain that cannot be quantified in percentages or even in euros, but it is clearly noticeable.