By Götz-Andreas Kemmner

Another buzzword has been added to the lexicon of business management: sales & operations planning. We’ll tell you what it’s all about and why you should look into it in our two-part article, which we start today.

The ideal image of modern production logistics is characterized by the idea of market-synchronous production: producing what the market needs. Ideally not in advance, but just in time. This ideal version of market-synchronized production is hardly economically feasible in any company today – if it ever was.

Customers and markets are far too “impatient” for that. They demand a high level of readiness to deliver, want short delivery times and on-time deliveries. The increasing number of variants in product portfolios further exacerbates this problem. In most cases, therefore, only a moderate increase in demand is spread across a broad product portfolio, which reduces demand for the individual product and causes it to fluctuate overall. In practice, we regularly hit our heads against the ceiling when trying to produce this widely distributed and fluctuating demand in line with the market: the capacities in production, the available personnel or the suppliers’ ability to deliver are not sufficient.

Strategy mix against impatience

How can you deal with such a market environment as economically as possible?

Five strategies are available to help you overcome this challenge:

- You increase production flexibility in such a way that you can follow every hook that market demand throws at you. This usually requires you to maintain higher production capacities or, if you are not yet producing around the clock and around the week, to allow your personnel capacity to fluctuate. However, this not only costs overtime and special bonuses, but often also requires a generally higher number of staff. The advantage of this strategy is usually low inventories in the value chain.

- Instead of demanding a high degree of flexibility from the value chain, you can also try to seal off production from the market firestorm with a firewall of inventories. Such a firewall is always possible at the logistical decoupling point – for make-to-stock manufacturers, typically at the finished goods warehouse, for variant manufacturers at the component warehouse before assembly. Although this results in high inventory costs, you save on flexibility costs in production. This comparison of flexibility costs with inventory costs is always the first strategic starting point for the economic optimization of the supply chain. It is not uncommon for the total costs to remain too high and we have to try to take further measures.

- One frequently used method is to reduce delivery readiness. As we all know, the required safety stocks virtually explode when delivery readiness levels exceed 95%. Every half percent reduction in delivery readiness can save considerable inventory costs and, of course, increase liquidity.

- Just as a reduction in delivery readiness reduces the necessary inventory costs, an accepted delay in delivery reduces the necessary flexibility costs in production. Of course, these two strategies do not come for free either. At the very least, there is a risk that customers will jump ship and we will lose sales to competitors. Unfortunately, it is rarely possible to calculate exactly how high the opportunity costs for this are. However, anyone with a few years of practical experience knows that these costs do arise.

- As a last resort, you can try to educate customers to be patient. The European automotive industry is particularly successful on this supposedly ideal path. We are almost conditioned to develop doubts about a selected car when we learn that the car we want to order has a short delivery time. But even the automotive industry is losing customers due to long delivery times. This strategy can only be used by actual or perceived monopolists. There are few of the former, but plenty of the latter – who drives the “wrong” brand of car, buys the “wrong” brand of watch or switches from one long-standing and inexpensive supplier to another? If customers absolutely need the products, a monopolist can perhaps expect them to grudgingly wait in the short term. But perceived monopolies cannot withstand this for long!

What does the SOP do now?

The core task of Sales & Operations Planning (SOP) is primarily to ensure the most economical market supply possible through a suitable mix of the five strategies mentioned. This is a noble demand that many companies fail to meet in practice.

In addition, the SOP usually has to deal with two other tasks: In general, markets and the demand for them develop differently than the original business plan once envisaged. Deviations from the sales plan, including the associated development of inventories, capacity utilization and personnel resources, must be identified and analyzed. This is the only way to draw the right conclusions in terms of investment and marketing. Such deviations from the plan should also be identified and the necessary measures coordinated as part of the SOP process.

Ultimately, the start-up of new articles and the phasing out of old ones are key planning tasks for the SOP. Sales and Operations Planning is also required to ensure that the markets are supplied on time and in sufficient quantities and that no excess or remaining stock is created when products are discontinued.

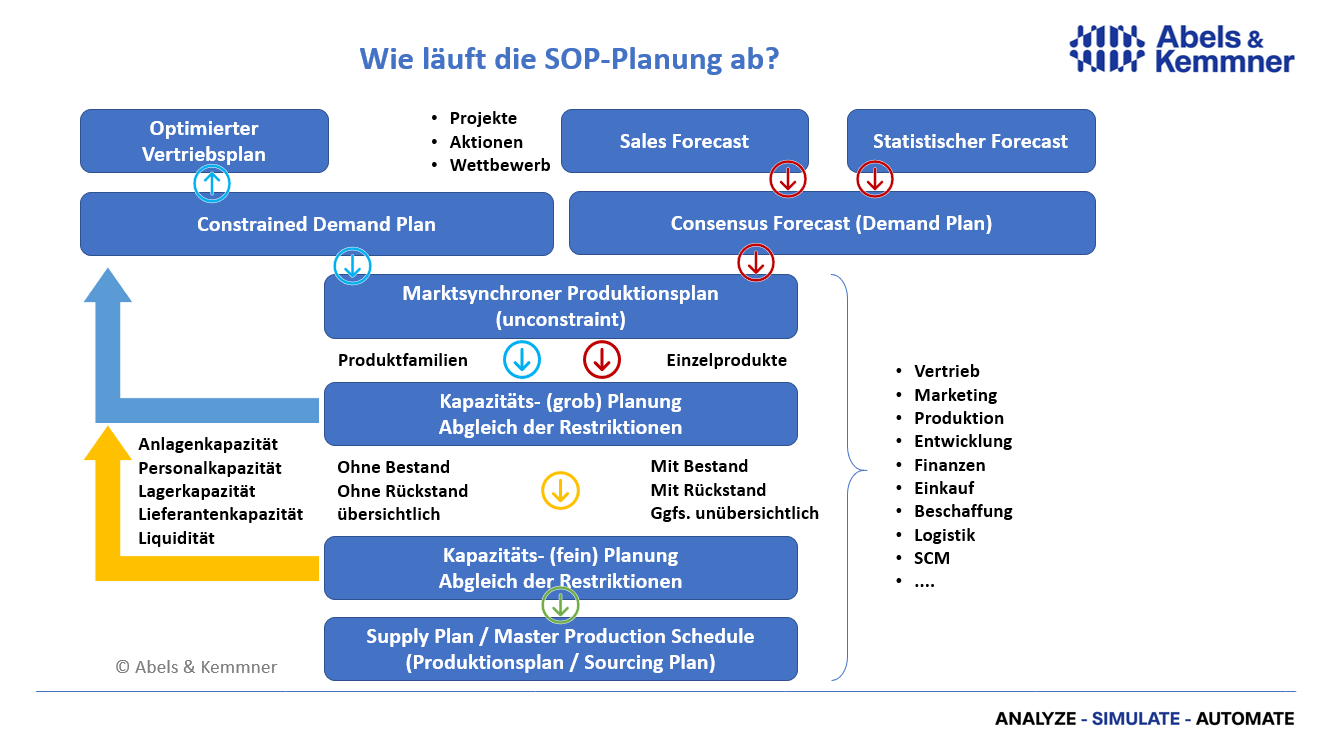

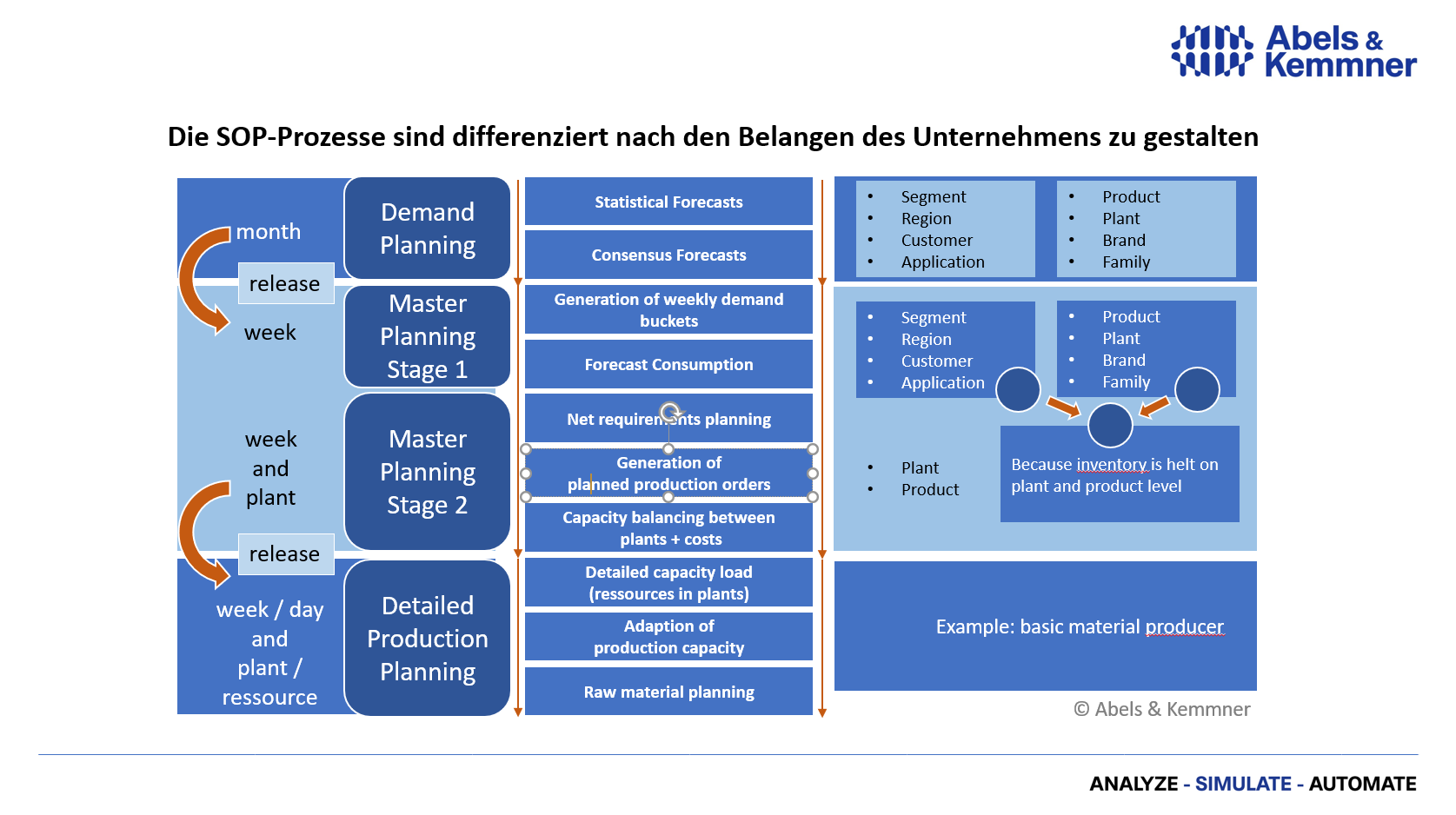

The individual constraints of a company and its markets have a strong influence on sales and operations planning. For this reason, there can be no “standard sales and operations planning process”. Nevertheless, certain basic mechanisms can be recognized that regularly occur in SOP processes (Fig. 1).

Fig. 1: Sales and Operations Planning process in the diagram

It all starts with the sales plan

The starting point of an SOP process is often a statistical forecast, which is then adjusted to a greater or lesser extent by the sales department. Above all, the sales department must incorporate information about projects, campaigns and competitive developments into the planning process. From this, an initial coordinated forecast can be developed in the form of a demand plan, often referred to as a “demand plan” or “consensus forecast”.

From this demand plan, a market-synchronized production plan can be developed largely mechanically, which does not take into account any major restrictions in terms of available capacity. Depending on whether the sales plan was developed at the level of product families or directly at the level of individual products, the market-synchronized production plan also focuses on product families or individual products.

Second step: capacity planning

The next step is to carry out more or less detailed capacity planning. The most important restrictions that may need to be taken into account are

- the system capacity,

- the personnel capacity,

- the storage capacity,

- the transport capacity, if applicable,

- the unfortunately often neglected supplier capacity and

- possible liquidity restrictions.

If planning is carried out at product family level, it is not normally possible to take open stocks and any order backlogs into account in capacity planning because these two variables always relate to a specific material number or order backlog. refer to a specific article. But the planning is clearer. If capacity reconciliation is carried out at the individual product level, it is possible to plan more precisely and take stock levels and back orders into account when reconciling capacity. However, this also makes capacity leveling more complex and confusing. Splitting capacity leveling into a rough-cut and a detailed planning step is therefore often the method of choice to make use of both advantages.

Effective S&OP is a meeting point for Sales, Marketing, SCM, Production and Purchasing to create a feasible production plan.

Third step: Recursion

The existing capacity restrictions should have an impact on demand planning and thus lead to a corrected demand plan. This means that some of the originally planned requirements can be brought forward and some can be canceled if they cannot be met in terms of capacity. This resulting, corrected demand plan must now be realizable with the available resources. At the end of the SOP process, the result is a production plan that can be implemented with the available capacities and resources and that must be realized!

However, capacity leveling can also reveal capacity reserves that are available for the manufacture of certain products in excess of their actual required quantity or excess stocks of products. The fine art of Sales & Operations Planning now consists of deciding which of these excess quantities could be sold on the market through sales activities and which free capacities should be used to produce further products in excess of expected demand. The corresponding quantities must be included in an optimized sales plan as a sales target for the sales department.

Further information on this topic can be found here:

Image rights: © Jorma Bork / pixelio.de