Before Christmas, in issue 4/2013 of POTENZIALE, we explained the concept of Sales & Operations Planning (SOP) and the five strategies that will help you to use SOP to absorb the whims and impatience of the market as skillfully as possible. The result of a successful SOP process is a feasible production plan that takes your company’s capacities and resources into account. But what exactly does the implementation of an SOP process look like and which departments are affected?

The results of the SOP process naturally affect a whole range of areas in the company, which are often difficult to reconcile:

- Distribution,

- Marketing,

- Supply Chain Management,

- Production,

- Purchasing,

- Procurement,

- Logistics,

- Finances and

- Possibly also development

all want to be considered with their priorities and needs.

The major management challenge of SOP planning now lies in finding a fair and feasible compromise that everyone involved can agree to. Not least for this reason, as already shown in Part 1 , there is no standard SOP process.

Global SOP process in detail

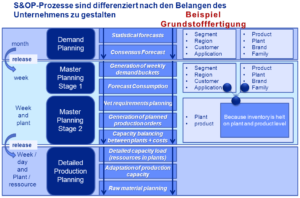

Figure 1 shows the concept of a global SOP process that we have developed for a group from the basic materials production sector.

Two key elements of this process are the statistical forecast and two-stage capacity leveling.

The statistical forecast at the start of the process is intended to ensure that an objective planning basis is used, which can then be further specified by the sales department. The two-stage capacity leveling enables a simpler, initial capacity leveling at a coarse level before the stocks and back orders are taken into account in a second, finer step at individual product level and the remaining capacity imbalances are balanced out.

Even if the individual SOP processes of companies sometimes differ significantly, we face some typical challenges in SOP planning.

These challenges can be divided into four areas:

- ensuring sufficient quality of the input information,

- the design of a process that is as responsive as possible,

- the consistent fight against the existing planning restrictions and

- the consistent use of SOP results.

Distribution and SCM – two worlds …

In order to ensure the quality of the input information for the SOP process, cooperative collaboration between sales and supply chain management is required first of all. This is not always easy. Sales is generally concerned with increasing sales, while supply chain management focuses on the total costs of the value chain.

When it comes to considering future requirements, the sales department usually thinks in terms of product groups and is interested in the long-term trend of market development. Supply chain management, on the other hand, plans in units of individual products or SKUs and is more interested in short- to medium-term changes in demand that are relevant to scheduling.

Forecasts of market requirements are essential

If you start the SOP process with statistical default values and do not require the sales department to provide information on all individual products, you are already on the safe side. It is then often sufficient to request sales information only for those articles for which the statistics are not sufficient. In principle, however, you need statements on projects or campaigns from Sales as well as information on special market developments for the planning process. Make sure that the sales department comments on future market requirements and not on its original budget-relevant expectations. In practice, the latter will occur quite frequently, hence this note.

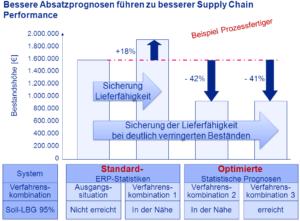

The importance of a good sales forecast for the outcome of the entire SOP process, the supply chain and market supply is often underestimated. The drastic figures from the project at a process manufacturer are intended to illustrate the true importance of a good sales forecast(Fig. 2).

Our analyses in this project showed that with the existing quality of the sales forecast, almost 20% more stock would have had to be built up to ensure the required delivery capacity. On the basis of an improved statistical forecast, however, the required delivery readiness was achieved with 40% less stock.

Central procurement management reduces response time

But it is not only the quality of the statistics as such that is important for the quality of the forecast results. The quality of the input data used in the statistics is also of great importance.

If the demand forecast for the entire supply chain can be based on point-of-sale data, this not only enables significantly lower stock levels at all warehouse levels, but also greater flexibility and faster reactions throughout the entire supply chain. A few industries are already trying this in the form of CPFR (Collaborative Planning, Forecasting and Replenishment). In most industries and companies, on the other hand, requirements are passed upstream from inventory level to inventory level – from distribution to procurement.

However, the entire supply chain is able to react much more accurately and quickly if the issue data from the last stock level, often the sales figures at the point of sale, are passed on directly and used for central planning. In order to keep planning and inventories consistent, replenishment should also be managed centrally.

Independent restocking by the customer

VMI (Vendor Managed Inventory) solutions with customers are another helpful tool for recognizing customer requirements earlier and responding more flexibly. Instead of working together in the traditional way via ordering and delivery, the VMI concept enables the customer to restock independently and frees them from waiting for customer orders and meeting strict delivery deadlines. This VMI process is usually controlled by a minimum and a maximum stock level, which decouples the supplier from the customer’s order dictates and thus enables more flexible capacity planning. VMI concepts thus contribute to greater flexibility in capacity balancing within the SOP process.

A good SOP therefore requires a lot of cross-departmental communication, especially between SCM and Sales. However, this also makes the entire process susceptible to delay effects that slow it down. But how can you release this “process brake” and increase the responsiveness of the SOP process?

A key tool for this is higher planning frequencies and interim information during the month instead of only running the SOP processes on a quarterly basis. Because the latter almost inevitably means that every new plan leads to drastic changes. The jumps in change, on the other hand, are already smaller with monthly planning. To achieve this, the SOP process must be set up properly and be able to run through quickly.

Too much of a good thing, as always, has undesirable side effects: SOP planning on a weekly basis becomes too time-consuming and can lead to you running after every little snag the market throws at you. At the very least, however, you should track the planned/actual deviations below the month and the planning should be adjusted accordingly if defined threshold values are exceeded. This allows you to recognize shifts in demand earlier and significantly reduce the number of drastic planning fluctuations. Remember: Those who recognize developments earlier can react earlier – those who recognize developments too late have to take action.

Close communication is not only an advantage on the customer side in order to be able to react quickly in the supply chain and relieve the burden on SOP planning. The right coordination with suppliers is also important. It should be a matter of course in an SOP process that a coordinated supply plan is passed on to the suppliers as the result of an SOP process – but this is often not the case.

Give suppliers concrete goals

It does not hurt to bear in mind that it is not only the company’s own production facilities that are struggling with limited capacities, but also suppliers. In practice, however, it is unfortunately often the case that the necessary flexibility of the suppliers has not been sufficiently coordinated with them.

Example: A statement such as “20% more within 2 months” is not a sufficiently precise statement, but only raises new questions! Should 20% more quantity be delivered once after two months or should 20% more quantity be feasible every two months? Does the delivery quantity have to be increased spontaneously and continuously to 20% additional quantity after two months or is it sufficient if the additional quantity can be delivered at the end of the two months? The material releases and order horizons required for the desired supplier flexibility, within which the suppliers have to react, are very often underestimated by both customers and suppliers and are coordinated far too tightly. Reduce restrictions – don’t cherish them!

The quality of the results of a sales and operations planning process does not improve so much by becoming better at dealing with the existing restrictions. Rather, it is important to continuously reduce the number of restrictions to be taken into account. As a general rule, the number of restrictions increases the planning effort and opportunity costs of potential sales and customer losses, while the quality of the planning result decreases. One strategic task of SOP planning must therefore be to continuously reduce the number of planning restrictions to be taken into account in the SOP process.

Planning complexity also depends on the level of alignment between demand and supply, as we recognized in Part 1:

If it is sufficient to compare the restrictions on capacities and resources at the level of product groups or product families, this simplifies the comparison. However, the result is also coarser-grained. However, the accuracy is not only limited by the level of detail of the goods; in general, neither existing stocks nor order backlogs can be taken into account, as these are naturally available at individual material level.

On the other hand, if capacity balancing is attempted at individual material level, transparency can quickly be lost.

Ultimately, the expense of an SOP process is only justified and useful if its results are used consistently. That sounds banal, but it’s not.

Reliable values replace gut feeling

Detailed analyses of the entire planning process often interrupt the planning chain by overriding requirements planning at the level of production control and operational procurement, or, to put it more drastically, throwing it in the trash. Operational planners do not believe the default values and try to work on the basis of their own experience and gut feeling.

Of course, you need to avoid such a break in the planning chain. Often, however, the cause of this behavior lies more in the poor quality of the SOP planning results than in a lack of discipline on the part of the operational planners. Only communication and a clean SOP process can help here, so that the planners gain confidence in the values provided to them.

For SOP to really succeed, Demand and Supply must see themselves as a tightrope team and secure each other. Communication is essential here, especially if you want to involve customers.

Demand and supply go hand in hand

But even within the SOP process itself, the results achieved are not always consistently used and observed. In order to successfully climb the ridges of SOP planning, the demand side and the supply side must see themselves as a rope team. Sometimes one secures the other, sometimes it’s the other way around. The supply side should not only try to fulfill the needs of the demand side, but the demand side should also try to sell what can be provided on the supply side.

The icing on the cake must be to direct customer requirements towards existing products and surplus quantities and to coordinate actions with the supply side before they are offered on the market.

Efficient and effective sales and operations management is therefore a core process within the company. If you succeed in taking the design tips presented into account, you will have laid the essential foundations. What organization and IT cannot replace is the royal authority to bring all “electors” to the table and reach a joint decision.

Further information on this topic can be found here: