In the context of sustainable inventory management, it has proven successful not to simply work with blanket inventory targets for product groups or inventory levels, but to specify material-number-specific target inventory values and identify inventory reduction potential or the need to increase inventory. This provides users with an orientation value that shows them whether they are pushing stocks too high or too low by intervening in the orders and production orders proposed by the ERP system.

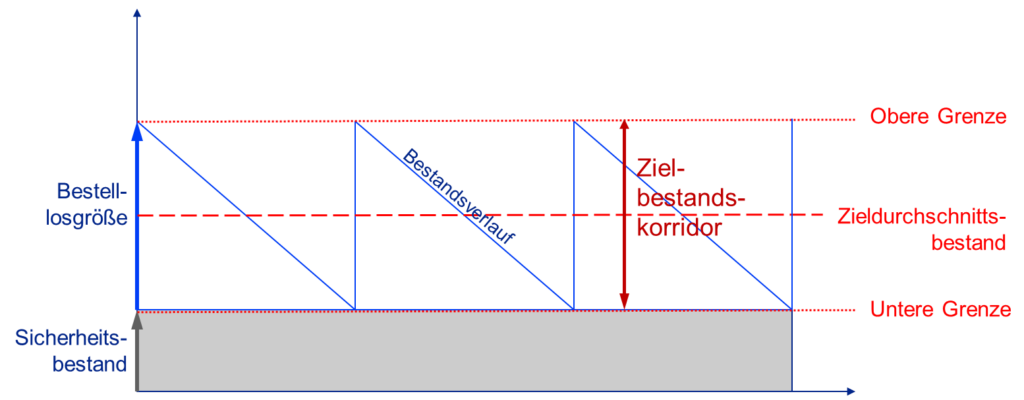

The target stock of an item is, strictly speaking, a target average stock. It results from the MRP settings of the ERP or merchandise management system. In relation to the individual item, a target stock level cannot be permanently maintained; instead, the stock level fluctuates around the target stock value. Ideally, the resulting actual average stock should correspond to the target average stock. In practice, the target average stock is therefore supplemented by an upper and a lower limit, between which the stock trend may fluctuate, and the breach of these limits is monitored in relation to the individual items.

Our tip:

As the target average stock level is derived from the MRP settings of the ERP or MRP system, the MRP parameters should be set up properly and set via a set of rules. This is the only way to ensure that the target portfolio fulfills its function as a reference value.

If you want to arrive at truly reliable target stock levels, you also need to determine the target stock level by simulation and not by a simple calculation from the planning parameters.

Image rights: © Rainer Sturm / aboutpixel.de